Install the cylinder block with the sump mating surface facing up.

Checking the operating clearance of the main bearings

Clean the bearing shells and the recesses of the working surfaces in both the cylinder blocks and the main bearing caps. If new liners are installed, make sure that all traces of protective grease are removed. Wipe the bearing shells dry with a lint-free cloth.

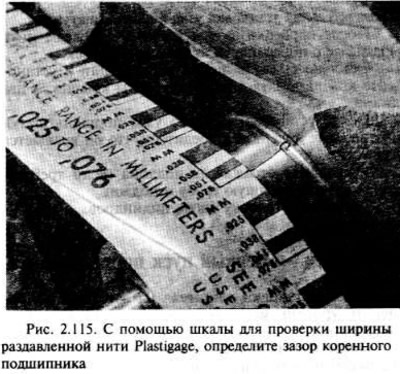

Before installing the crankshaft, it is necessary to check the clearances of the main bearings, which can be done in two ways. First, you can install the main bearing caps in the cylinder block along with the bearing shells. With the old cap bolts tightened to the correct torque, measure the inside diameter of each assembled pair of bearing shells using a dial gauge or micrometer. If you measure the diameter of each crankshaft journal, and then subtract it from the diameter of the liner, we get the value of the working clearance of the main bearing. Second (and more accurate) the way is to use an American product called Plastigage. It consists of a thin strand of perfectly round plastic material that is compressed between the bearing shell and the crankshaft journal. Deformed plastic material can be measured using the special scale supplied with the Plastigage kit.

Compare the width of the warped Plastigage thread on each journal to the scale to determine the amount of main bearing clearance.

Carefully remove all traces of Plastigage from the crankshaft and bearing shells.

Final installation of the crankshaft

Carefully remove the crankshaft from the cylinder block.

Lubricate the lips of the new crankshaft rear oil seal and rotate it on the rear of the crankshaft. Do this carefully, the sealing lips are easily damaged. Make sure the open side of the seal is facing the inside of the motor.

Liberally lubricate each bearing shell in the cylinder block and lower the knees of the vases into place. Check that the rear oil seal is installed correctly.

When landing, the crankshaft can be gently tapped with a soft-sheathed hammer on the cheeks of the counterweight.

Lubricate the bearing shells, crankshaft journals, then install the bearing caps NN 2, 3 and 4 and tighten the new bolts by hand as far as possible.

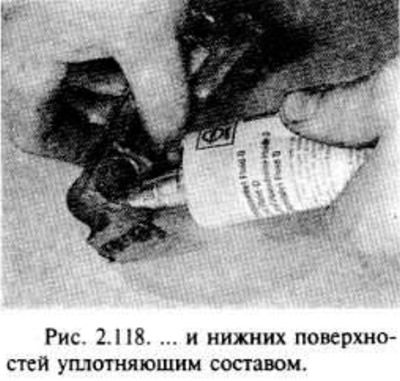

Fill the side grooves of the front covers (If you want to) and rear main bearings with joint sealing paste (paste Vauxhall/Opel pan N 15 03 294 or equivalent) and coat the bottom surfaces of the bearing caps with Vauxhall/Opel part N 15 04 201 sealant or equivalent). Install the bearing caps and hand-tighten the new bolts as far as possible. Make sure the front main bearing cap is level with the end face of the cylinder block.

Starting from the center main bearing cap outward, tighten the bearing cap bolts to specification in two steps.

After final tightening of all bolts, squeeze more sealing pastes into the side grooves of the front covers (If you want to) and rear main bearings and check that they are filled with paste.

Now you can scroll the crankshaft and make sure that it rotates freely without jamming.

Check the offset of the crankshaft along the axis.

Install pistons and connecting rods.

Install the oil pump.

Install the pallet reflector (If you want to), oil supply pipe and sump.

Install the cylinder head.

Visitor comments