Position the piston/connecting rod assemblies and new piston ring sets so that the ring sets match their piston and cylinder, and measure clearances and assemble the engine in sequence.

Insert the top ring into the first cylinder and push it down with the top of the piston. This will ensure that the ring remains perpendicular to the walls of the cylinder. Position the ring as close to the bottom of the cylinder as possible.

Measure the gap in the ring lock using a set of feeler gauges.

Repeat the measurement operations, but in the upper part of the cylinder, and compare the measurements with the required values.

If the gap in the lock of the ring is too small (which is unlikely if Vauxhall/Opel parts are used), it must be increased, otherwise the ends of the ring may close together during engine operation and cause serious damage.

If the rings are new, it is unlikely that the gap between the ends of the ring will be too large, and if the gaps are too large, check that the rings are correctly selected for your engine and in particular for a certain size cylinder.

Repeat the procedure for checking each ring for the first cylinder, and then for the rings of the remaining cylinders.

After checking the gaps, the rings can be placed on the pistons.

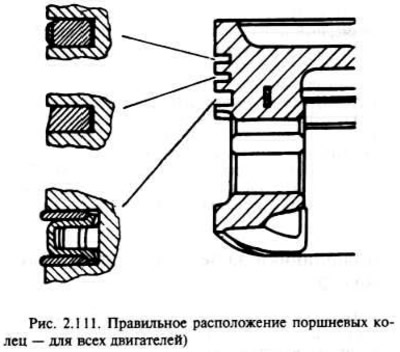

Oil scraper ring (bottom on the piston) consists of three sections and must be installed first. Install the lower steel ring, then install the expander and. finally, the top steel ring.

After installing the oil scraper ring, you can install the second (average) ring. It is usually labeled "TOR" (TOP) the side that should point towards the top of the piston. As with the removal of the rings, carefully slide the ring onto the middle groove using a feeler gauge.

Install the top ring so that the marking "TOP" corresponded to the location of the ring. If piston rings are installed with an overlapping lock, first of all install a ring with a smaller diameter.

Repeat operations with other pistons and rings.

Visitor comments