Engines with one camshaft

Removing

Note: The engine must be cold when removing the cylinder head.

Disconnect the negative lead from the battery.

Drain the coolant from the cooling system.

Disconnect the exhaust pipe from the manifold.

The cylinder head can be removed with the pipes, or the pipes can be removed from the head before removal (chapter 4).

If the cylinder head must be removed along with the pipes, disconnect all hoses, pipes and wiring from the intake manifold (chapter 4). On carbureted engines, disconnect the hot air hose from the exhaust manifold housing.

Disconnect the air cleaner line.

Disconnect the hose on the camshaft cover. On models with fuel injection, remove the wiring bolt.

For 1.4 and 1.6 liter engines, disconnect the breather hose from the nozzle.

Loosen the alternator mounting, then disconnect the top bracket from the intake manifold.

Disconnect, if required, the wiring of the fuel injection unit from the brackets on the camshaft cover, then disconnect the connector.

Make sure that all hoses, tubes and wires are disconnected, then unscrew the nuts, noting the location of the brackets (e.g. engine lift bracket), connected to the cylinder head studs and separate the intake manifold from the cylinder head.

Remove the intake manifold gasket. If necessary, remove the exhaust manifold (chapter 4).

Remove the camshaft sprocket, unscrew the two bolts of the upper rear cover of the distributor belt.

Disconnect the high voltage wires from the spark plugs and ignition coil by hanging labels on them. to make installation easier.

Disconnect the breather hose on 1.8L and 2.0L engines, unscrew the breather bracket bolt on the cylinder head.

Disconnect the hose (And) coolant from the thermostat housing.

On carbureted engines, disconnect the hoses from the fuel pump. Clamp the ends of the hoses to prevent fuel leakage.

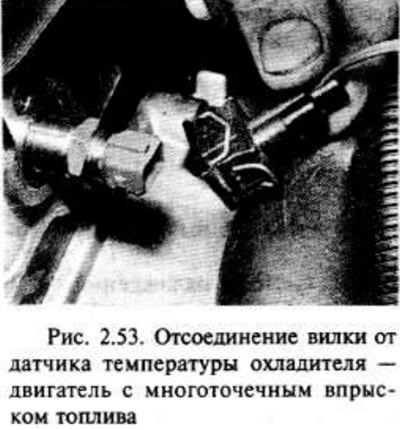

Disconnect, if required, the plug of the wire connector from the system coolant temperature sensor. Make sure all hoses, tubes and wires are disconnected.

In the sequence shown in the figure, loosen all the cylinder head bolts first by a quarter of a turn, then by half a turn, and finally unscrew them completely.

Separate the camshaft housing from the block head. If necessary, tap the body gently with a soft-shelled hammer, but do not lever it up against the mating surfaces.

Disconnect the head from the cylinder block in the same way.

Remove the rocker arms and gaskets, remembering their order for later installation.

Remove the hydraulic valve lifters from the cylinder head and arrange them in such a way that they can then be installed in their original position.

Remove the cylinder head gasket.

Installation

Clean the mating surfaces of the cylinder head and cylinder block, camshaft housing and cylinder head by carefully scraping off the dirt with a scraper. Be careful not to damage these light alloy parts as they can be easily scratched.

Cover the cooling system openings and other openings with adhesive tape or rags to prevent dirt and soot from entering. Wipe off any remaining oil in the bolt holes; if oil remains in the holes, the hydraulic pressure may cause cracks in the block while the bolts are being tightened.

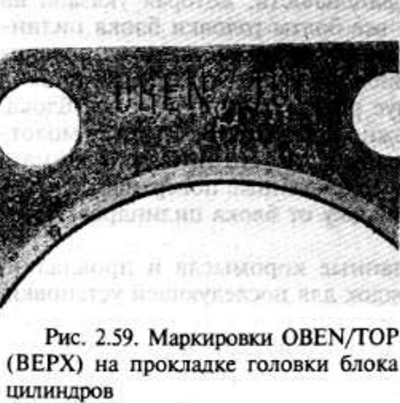

Start installing the cylinder head with a new head gasket on the block in this way. so that the word OBEN or TOR is visible from above (TOP), as indicated in the figure.

Before installing hydraulic valve lifters, we recommend disassembling and cleaning them (part of this chapter).

Install the hydraulic valve lifters, gaskets and rocker arms into the cylinder head. Lubricate the tappet holes generously with oil. Lightly lubricate the contact end surfaces of the valve tappets, support gaskets and rocker arms with molybdenum disulphide grease.

Temporarily install the crankshaft sprocket, making sure that the alignment marks are in position with the No. 1 piston at TDC.

Apply sealant (Vauxhall/Opel compound N 15 03 166, or equivalent) on the mating surface of the cylinder head, then install the camshaft housing and cylinder head.

Install new cylinder head bolts, making sure the washers are in place. Tighten the bolts by hand as far as you can.

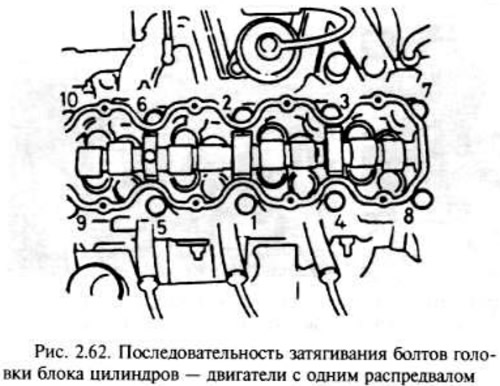

Tighten the bolts in the sequence shown in the figure. Tighten bolts in four steps to specification.

Installation is carried out in the reverse order, taking into account the following steps.

Make sure the high voltage wires are connected to the spark plugs.

Install the camshaft sprocket.

Install, if required, a manifold on the cylinder head, replacing the gaskets with new ones.

Connect the exhaust manifold pipe using a new gasket.

Install the alternator upper bracket on the intake manifold, adjust the alternator belt tension.

Fill the cooling system with coolant.

After starting the engine, check for signs of leakage.

Once the engine reaches normal operating temperature, check and. if necessary, adjust the idle speed and mixture quality. Finally, fully tighten the cylinder head bolts (fifth stage).

Engines with two camshafts

Removing the cylinder head

Disconnect the negative battery terminal.

Drain the coolant from the cooling system.

Disconnect the exhaust system (chapter 4).

The cylinder head can be removed together with the intake manifold, or it can be detached.

If the cylinder head is removed with the intake manifold, disconnect all hoses, lines, etc. (chapter 4) and remove the manifold bracket bolts. Loosen the alternator mounting, then remove the upper bolts.

If the intake manifold remains in the engine compartment, then the procedure will be as follows.

Disconnect the connector plug from the air flow meter and the breather hose from the throttle body, then disconnect the air cleaner line and remove the air flow meter (chapter 4).

Disconnect the end of the throttle cable from the lever, then unscrew the bolts, remove the intake manifold bracket.

Loosen the two wire nuts "mass" at the fuel distribution line (one at each end), and disconnect all three wires at "mass".

Disconnect the wiring harness plug from the throttle position sensor.

Pulling up the housing, disconnect the wiring from the injectors.

Disconnect the two breather hoses from the rear of the camshaft cover.

After loosening the fastening, unscrew the bolts at the top of the generator. Loosen the manifold bracket bolts.

Check that all hoses, pipes and wiring are disconnected, then, unscrewing the nuts, separate the intake manifold from the cylinder head.

Remove the manifold gasket from the cylinder head.)

Remove the camshaft sprocket.

Remove the timing belt tensioner and idler pulley. Unscrew the upper and middle clips of the outer belt cover (the upper latch is simply unscrewed, the middle one is fixed with a bolt). Unscrew the two bolts of the top rear belt cover.

Disconnect the ignition distributor cap and high voltage wires (chapter 5).

Disconnect the ignition distributor wire connector.

Disconnect the cooling system hoses from the left side of the cylinder head.

Remove the breather bracket bolt on the cylinder head.

Disconnect the upper radiator hose from the thermostat housing and the wiring from the temperature sensors in the cooling system (both in the thermostat housing).

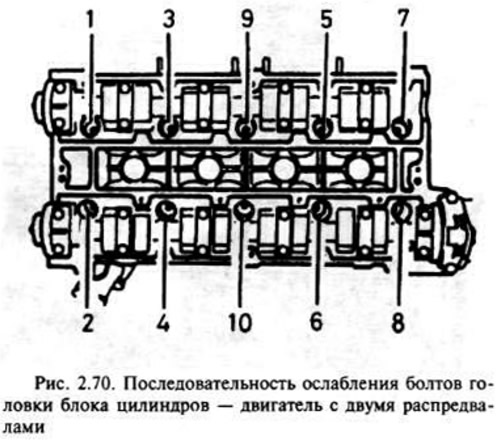

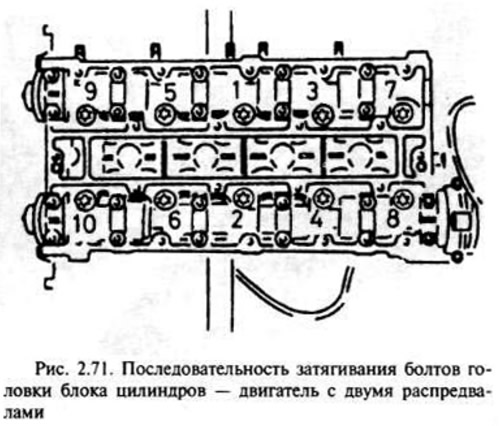

Using a socket wrench or Torx bushing, perform the operations in the sequence shown in fig. 2.70: loosen all bolts a quarter, then half a turn, and finally loosen and unscrew the bolts completely.

Raise the cylinder head. If necessary, gently tap it with a soft-shelled hammer. however, it must not be pryed with a lever over the mating surface. Remember that the head is located on the dowel pins. Remove the pad.

Installation

Remove dirt from the mating surfaces of the head and cylinder block by carefully scraping it off with a scraper. Be careful not to damage the head, it is made of light alloy and can be easily scratched. Cover the openings of the cooling system, etc. with adhesive tape or rags to prevent dirt from entering them. Wipe off all traces of oil from the bolt holes; if oil remains, hydraulic pressure may cause cracks in the block during bolting.

Begin installation by placing the new gasket on the block with the word OBEN or TOP on top (TOP).

After thoroughly cleaning the mating surfaces, position the head on the cylinder block so that the installation fonts fit into the holes.

Temporarily install the crankshaft pulley and camshaft sprockets; make sure piston no. 1 is installed in BM 1.

Install new cylinder head bolts with washers and tighten the bolts by hand as far as possible.

Tighten the bolts in the sequence shown in the figure. Tighten bolts in four steps to specification.

Further installation is carried out in the reverse order of removal, taking into account the following.

Install the belt tensioner and idler pulley, camshaft sprockets and a new belt, adjusting its tension.

If required, connect the intake manifold to the cylinder head with a new gasket.

Connect the exhaust section by installing a new gasket.

Tightening the alternator mounting bolts to the intake manifold (where required), adjust the alternator belt tension.

Pour coolant into the cooling system.

Check if all hoses, pipes and wiring are connected.

After starting the engine, check for signs of leakage.

After the engine reaches normal operating temperature, carry out the last tightening of the cylinder head bolts according to the fifth step.

Visitor comments