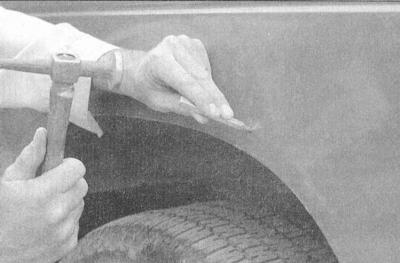

2....then screw the hammer shaft into the hole and actuate it. Tap the edge of the dent with a mallet to help the metal return to its original shape. After the end of this procedure, the surface of the dent should approach its original contour and protrude approximately 0.3 cm above the surface of the surrounding metal.

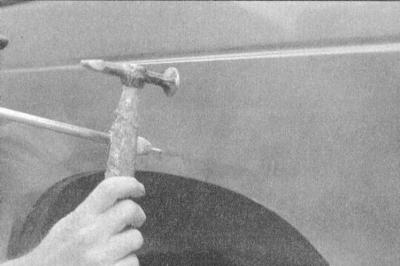

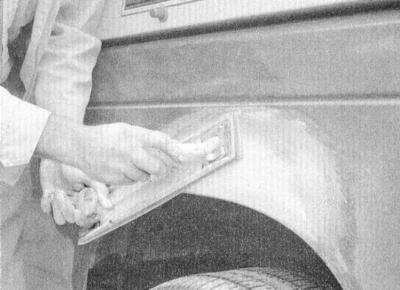

3. Using coarse sandpaper, remove the paint to bare metal. You can do it by hand, but the tool shown in the photo will help you speed up the process. Using a finer, approx. 320 grit sandpaper, wipe away the paint within a radius of at least 2.5 cm around the dent area.

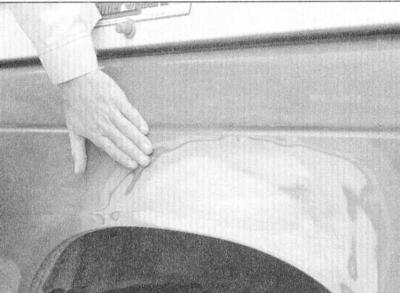

4. After removing the paint, it is better to check by touch than by sight whether the metal surface is sufficiently even. Hammer out the bulges and/or pull out the cavities where necessary. Clean the surface to be restored with a wax or silicone stain remover.

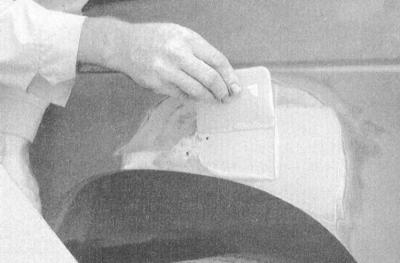

5. Following the instructions on the package, mix the pack of plastic putty with the hardener. The mixing ratio is critical, and if you break it, the putty will harden too slowly or too quickly (and you will not have time to apply it and give the desired shape).

6. Working quickly to prevent the putty from setting, use the plastic applicator to apply pressure to the surface of the metal, making sure it fully engages with the metal. Treat the putty so that it takes a shape close to the original shape of the site and slightly rises above the surrounding surface.

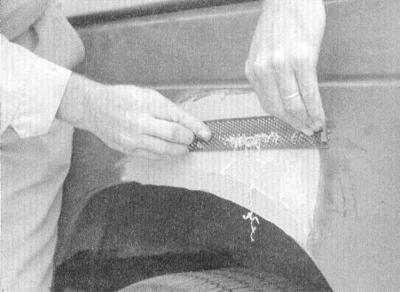

7. Let the putty harden to such a state that it can only be pushed through with a fingernail. Using a file or the tool shown in the photo, roughen the putty.

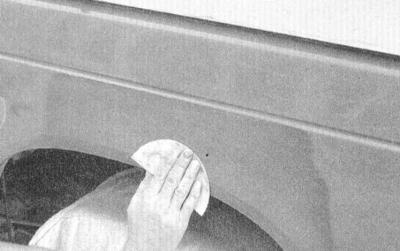

8. Using coarse sandpaper, mounted on a plank or bar, process the putty so that it becomes smooth and even. Gradually move to thinner and thinner grades of paper, always using a plank or block, and finish with number 360 or 400.

9. As a result of processing, the hand should not feel the boundaries of the transition from putty to bare metal and from bare metal to old paint. If this goal is achieved, remove dust and cover adjacent panels and trim.

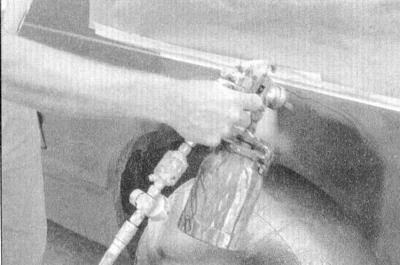

10. Apply several coats of primer to the surface to be treated. Don't overspray the primer so it doesn't run off, and after applying each coat, let the previous one dry. Usually a professional spray gun is used here, but auto parts stores have a primer in an inexpensive aerosol can.

11. The primer will help to reveal defects or scratches. Fill them with polishing paste. Following the instructions on the package, process it with a thin (No. 360 or 400) sandpaper until smooth. Repeat polishing by applying polishing paste and sanding until the primed surface is completely smooth.

12. Finish sanding with very thin paper (No. 400 or 600), to remove excess primer. Wash the treated area with water and let it dry. Use a sticky cloth to completely remove dust, then apply a coat of exterior paint. Do not attempt to wipe or wax the area until the paint is completely dry (at least two weeks).

Repairing easily scratched paintwork

1. If the scratch is superficial and does not affect the metal of the body panel, the restoration of the paintwork is extremely simple. To remove loose paint particles and wax, lightly rub the defective area with fine sanding paste. Rinse the treated surface with clean water.

2. Using a small brush, fill in the scratch with the same type and color of paint that was used to paint this panel. Continue applying paint layer by layer until the bottom of the scratch is level with the surface of the surrounding body panel paintwork. Allow the paint to cure for at least two weeks, then carefully sand the transition area using a fine sanding paste. Finally, wax the restored panel.

3. If the scratch has penetrated the paint and reached the metal of the panel, causing the development of corrosion, the restoring repair must be carried out using a different technology. Use a penknife to scrape off powdered rust from the bottom of the scratch, then treat the damaged area with a corrosion inhibitor to prevent future corrosion. Using a hard rubber or nylon applicator, fill the damaged area with a gloss type putty. If necessary, which is especially useful when removing narrow deep grooves, the putty can be diluted with a special solvent. Before the putty hardens inside the scratch, wrap your fingertip in a soft cotton cloth, dip it in the solvent, and quickly run it along the scratch. As a result, the surface should become slightly concave. Now, after the putty has hardened, the treated area can be painted using the technology described in the first part of this subsection.

Dent Repair

1. When repairing deep dents, the first task is to pull out the deformed surface of the body panel in order to restore its original shape. Note that it makes no sense to achieve 100% compliance with the original, especially since this is unattainable due to irreversible damage to the internal structure of the metal at the moment of impact. It will be enough to bring the deformed surface to a level located 3 mm below the surface of the surrounding undamaged part of the panel.

If the dent is shallow, pulling it out generally loses all meaning.

2. If the deformed area can be approached from the back side of the panel, you should try to straighten the panel from the inside by tapping the metal with a soft-faced hammer. At the same time, a wooden block should be pressed tightly against the front side of the damaged area in order to extinguish the impact impulse and to avoid excessive bending of the restored metal.

3. If the dent is located on the two-layer section of the body panel, or access to the latter from the back of it is impossible for any other reason, the method should be changed. Drill several small holes in the most heavily deformed areas of the dent, then screw long self-tapping screws into them, leaving the heads of the latter sticking out above the metal surface. Now proceed to pull the metal by grasping the screw heads with self-locking pliers.

4. At the next stage of processing, the damaged area and the surface of the panel surrounding it to a width of approximately 3 cm should be completely cleaned of paint. This work is best done with a wire or grinding attachment to an electric drill. No less effective paint stripping can be done manually using sandpaper. The final step in preparing the surface for puttying is to roughen the exposed metal of the dent by scratching it with a screwdriver or a piece of file, or by drilling small holes. The roughness of the surface increases the efficiency of adhesion of putty paste to it. Then you can proceed to puttying and painting the treated area (see below).

Repair of rusted holes and holes

1. Using a sander or wire attachment to an electric drill, remove all paint from the damaged area and in an area about 3 cm wide around it. No less effective work can be done manually with sandpaper. Having cleaned the surface of paint, it is possible to assess the degree of damage to the metal by corrosion and decide on the advisability of repairing the panel (perhaps it would be wiser to replace it entirely, if in principle it is possible). New body panels can often be purchased not for as much money as it seems - it is enough to spend a couple of days driving around city showdowns and car dumps.

2. Remove all body trim from the damaged panel, with the exception of those that can serve as a guideline when restoring the original shape of the damaged area (for example, facing of block headlights, etc.). Using scissors for metal or using a hacksaw blade, remove all loose, loose, and hopelessly corroded pieces of metal. Using a hammer, bend the edges of the hole inward to form a recess for placing putty material in it.

3. Use a wire brush to remove powdered rust from the damaged area. If you have access to the underside of the panel, treat it around the damaged area with a corrosion inhibitor.

4. Before proceeding with puttying, the hole should be plugged. This is usually done by gluing or screwing a piece of tin, fine wire mesh, or aluminum foil to the back of the panel in the damaged area. Having securely blocked the hole, you can proceed to puttying the panel and its subsequent painting (see below).

5. The best material for plugging large holes is fiberglass or a fine-mesh plastic mesh. Having cut a piece of material that is suitable in size, insert it into the hole and overlap it on the back of the panel with lumps of putty paste.

6. For sealing narrow holes, aluminum foil, available in the form of adhesive tape, is best suited. It is enough to remove the protective film and glue the foil on the back of the body panel, firmly plugging the hole. For the purpose of strengthening the foil can be glued in several layers.

Puttying and painting

Currently, the chemical industry offers a wide range of different body putties to the attention of buyers. However, for this type of work, the two-component putty paste offered with the kits for repairing body panels with the hardener attached to it in a tube is best suited. To achieve smoothness and regularity of the putty surface, the paste should be applied with a flexible rubber or nylon applicator.

1. Strictly following the manufacturers instructions (violation of them can lead to incomplete hardening of the putty mass), knead a little putty on a clean wooden plank, or a sheet of cardboard. Try to use the hardener carefully.

2. Using the applicator, apply the prepared mixture to the treated (see above) the surface of the damaged area of the body panel. To obtain the correct contour of the surface to be removed, each stroke with the applicator should go through the entire length of the restored area. As soon as the shape of the restored area of the panel approaches the original, immediately stop applying the putty, as it, while curing, will begin to stick to the applicator, forming lumps and leaving furrows on the treated surface. Continue to apply putty layer by layer at intervals of about 20 minutes until the surface level of the repaired area is slightly above the surrounding metal of the undamaged part of the panel.

3. After the paste hardens, the excess putty mass can be removed with a scraper or file. The next step is sanding and polishing. This work is best done with waterproof sandpaper with a uniform grit and strong abrasive adhesion (preferably imported). Sanding should be started with coarse-grained paper No. 40, progressively reducing the grit to No. 400. In order to achieve adequate flatness of the sanded surface, the paper should be wrapped around a block of dense rubber, wood or foam (for convenience, paper can be pasted on a bar). During the surface treatment, the paper should be regularly and frequently wetted with water. The described technology makes it possible to achieve absolute smoothness of the restored surface at the final stage of grinding.

4. On completion of sanding, the machined area should be surrounded by a ring of clean, bare metal, ending in a gradually fading edge of undamaged paintwork. Rinse the treated area of the panel with clean water, washing off all the abrasive formed during grinding, then dry the surface thoroughly.

5. From an aerosol can, spray the treated surface, covering it with a thin layer of a light primer, which will help to identify any mistakes made during the grinding process. Detected defects are then eliminated by re-puttying. Repeat the sanding step. Continue in the same vein until you achieve the desired shape and smoothness of the restored section of the panel. Finally, don't forget to rinse the panel with clean water and dry it.

6. Now you can proceed to staining. Work with the spray gun should be carried out with still air in a dry, warm and dust-free room. If circumstances force painting outdoors, the choice of suitable weather conditions should be taken seriously. When working indoors, beat the dust by spraying the floor with water. If only a section of the bodywork is being painted, cover the surrounding undamaged panels with old newspaper and secure them with duct tape. Finishing elements such as chrome decorative strips, door handles, headlight trim, etc., are best removed from the body panel during the painting stage.

7. When using paints supplied in aerosol form, shake the can thoroughly, then spray a test surface, practicing painting technology. Cover the surface prepared for painting with a thick layer of primer. The thickness of the coating should be achieved by repeatedly applying paint in thin layers. Spare no water, sand the prepared surface with fine-grained sandpaper No. 400. Allow the primer to dry completely before applying decorative paint.

8. Start applying decorative paint in thin layers to the primed surface. Start painting from the center of the area to be restored, making circular movements with a hand with an aerosol can / spray gun, expanding their radius in a spiral and not stopping until the entire prepared area is covered with a layer of fresh paint with an overlap of three to five centimeters. After 10-15 minutes (better not later, so as not to damage the edge of the paint that is starting to dry out) after applying the last layer, peel off the adhesive tape covering the surrounding body panels and remove the newspapers.

9. The final polymerization of the paint occurs after about two weeks, after which, to smooth the transition from fresh to old paint, rub the restored surface with a thin polishing paste. Finally, wax the panel.

Restoration of plastic components

Cracked plastic components should be repaired by a specialist. The technology is based on the use of a drill machine for turning a groove along the crack, into which a plastic rod is then placed from the same type of plastic as the repaired part itself. Next, the halves of the cracked panel are soldered to each other using a special hair dryer. Excess plastic is removed by grinding.

Less serious damage can be repaired by the amateur mechanic by filling the defect with a 2-component epoxy (the technology is similar to that used for puttying damaged areas of metal body panels).

When replacing a damaged plastic component, care must be taken to select a replacement panel that matches the color. Special paints and primers should be used to touch up parts made of plastic - ask in car accessories stores and strictly follow the manufacturer's instructions.

Visitor comments