Air conditioning system

The air conditioning system is constantly under high pressure. Never disconnect refrigeration lines or remove any system components without first discharging the system. The discharge of the air conditioning system must be carried out by an experienced specialist in a car service workshop. Always wear safety goggles when disconnecting refrigerant lines!

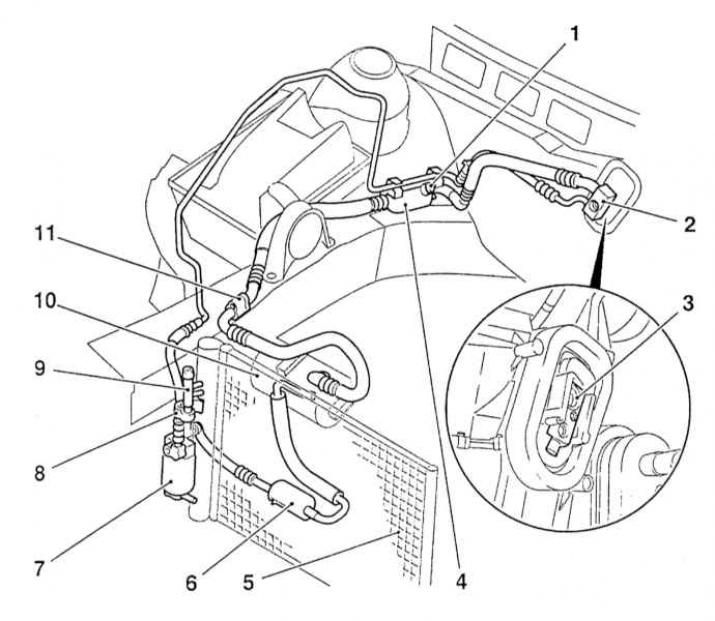

Components of a typical air conditioning system (Zafira models)

1 - Service connector of the low-pressure circuit

2 - Bolted union connection

3 - Expansion valve

4 - Pulsation damper

5 - Capacitor

6 - Pulsation damper

7 - Receiver-drier

8 - Pressure sensor

9 - Service connector of the high-pressure circuit

10 - Compressor

11 - Bolted nipple connection of the refrigerant tube

The following checks should be carried out on a regular basis to keep the air conditioning system in good working order:

- Check the condition of the compressor drive belt. If defects or signs of wear are found, replace (see chapter Current service).

- Check the tension force of the drive belt, if necessary, make the appropriate adjustment (see chapter Current service).

- Check the hoses of the refrigeration path for cracks, swelling, signs of hardening and aging of the rubber, evaluate the condition of the fittings. Replace defective components.

- Check the condenser coil plates for insect debris, old leaves, and other debris stuck between them. If necessary, clean the gaps with a thin brush, or blow them with compressed air.

- Check the system charge level.

- If water leaks are found on the floor mats under the instrument panel, remove the condensate drain pipe from the evaporator casing and check the patency of both holes with a piece of wire.

The air conditioning system must be switched on for at least 10 minutes at least once a month (even in the winter season). Prolonged inactivity of the A / C leads to hardening and failure of the sealing rings and cuffs of the connecting path.

Leaks that occur in the path are best manifested by increasing the operating parameters of the system (temperature and pressure), - leave the air conditioner on for 5-10 minutes with the engine running. Leak sources can be identified by oil drips.

Due to the complexity of the system design and the need to use special equipment, its maintenance, in-depth diagnostics and refurbishment are beyond the qualifications of an average amateur mechanic and must be carried out in a car service workshop. Only the simplest checks and replacements listed below in this Section fall within the competence of the owner of the car.

If the system does not function at all, check the condition of the appropriate fuse and relay.

The most typical cause of a malfunction in the functioning of the A/C is a decrease in the charge level of the refrigerant oil. The following simple checks will quickly identify signs of a low refrigerant level.

Checking the charge level of the refrigerant

1. Warm up the engine to normal operating temperature.

2. Turn on the A/C for maximum cooling capacity. Select the maximum fan speed. Open the doors to avoid cycling the system when the enclosed air volume in the cabin cools.

3. The operation of the A/C compressor clutch is accompanied by a distinctly audible click, after which the central part of the clutch should begin to rotate. After the temperature of the system reaches the operating temperature, feel the two pipes connected to the evaporator on the bulkhead of the engine compartment.

4. The thinner tube leading to the evaporator from the condenser outlet should feel cold enough to the touch. The thicker tube from the evaporator outlet back to the compressor should be a little more (2-6 degrees) colder. If the exhaust pipe is noticeably warmer to the touch than the inlet, then the system needs to be recharged. Insert the thermometer into the air outlet duct through the central vent on the instrument panel. With the K / V turned on, the temperature of the air leaving the deflector should be 2-4.5 degrees lower than the ambient temperature (up to 4.5°C). In very hot weather (above 40°C), it is permissible to increase the output temperature to a level of 15.7°C, but no more. If the air conditioner does not provide the required intensity of air cooling, the system should be recharged. For a more detailed diagnosis of the state of the system, the car should be driven to a specialized workshop.

5. Look into the viewing window, usually provided in the cover of the receiver-drier assembly - foaming of the refrigerant inside the receiver indicates a drop in its level. In hot weather, bubbles in the viewing window may be present even at a normal level of the working fluid - after turning off the system, foaming should stop.

Adding refrigerant

To charge the air conditioning system of the vehicles covered in this manual, use only refrigerant oil R-134a.

1. Prepare the standard charging kit R-134a (ask at car accessories stores). The kit includes a bottle of refrigerant oil, a valve nozzle and a piece of hose connected between the valve and the fitting of the low-pressure part of the refrigeration tract. Only refrigerant oil R-134a should be used, never R-12); the container must be 12 ounces (Ounce). Since one can of oil may not be enough to fully charge the system, it makes sense to buy a couple at once just in case. Make sure that at least one of the cans is tinted with red oil, which will allow you to quickly identify refrigerant leaks if they occur.

Never fill the system with more than two cans of refrigerant!

2. Connect the charging kit to the LOW PRESSURE section of the refrigeration circuit, following the manufacturers instructions.

Do not attempt to connect the kit to the fitting of the high-pressure part of the duct! The design of the fitting connections allows the set to be connected only to the low-pressure part of the system.

3. Close the valve on the adapter and screw the adapter onto the cartridge head, making sure that the o-ring/rubber seal is present.

Be sure to wear safety goggles!

4. Remove the dust cap from the fitting of the low-pressure part of the refrigeration circuit and connect the hose of the charging set equipped with a quick connection to it (see illustration Components of a typical air conditioning system (Zafira models)).

The design of the choke units will not allow the connection of the set to the high-pressure part of the tract.

5. Warm up the engine to normal operating temperature and turn on the A/C. Make sure that the charging kit hose does not come into contact with the cooling fan blades and other moving components in the engine compartment.

6. Rotate the valve nozzle to pierce the head of the cartridge, thereby opening the refrigerant supply (you should hear the characteristic sound of escaping gas). During the entire charge, hold the can strictly upright, shaking it from time to time. Charging should be interrupted when the temperatures of the evaporator inlet and outlet tubes are equal. Between charging series, pause to allow the system to stabilize.

Never add more than two bottles of refrigerant to the system! Wrap a towel soaked in warm water to prevent icing on the can during refilling.

7. If you have an accurate thermometer at hand, insert it through the deflector into the central air duct K / V and follow it for the temperature of the air supplied to the passenger compartment.

8. When the cartridge is empty, close the valve and disconnect the hose from the system's low-pressure connection. Replace the dust cap immediately.

9. Disconnect the valve nozzle from the cartridge, if necessary, move it to the second cartridge and continue filling. Upon completion of the procedure, place the unfinished cartridge upright on the rack and use it as needed to recharge the system.

Heating system

If the heater does not provide adequate heating of the air supplied to the passenger compartment, the reason for such a failure may be one of the following:

- The thermostat is stuck open, preventing the engine coolant supply to the heater heat exchanger from reaching normal temperature. Replace thermostat (see Disconnecting and replacing cooling system hoses);

- There is a violation of the patency of the cooling tract, which blocks the supply of coolant to the heater heat exchanger. Feel the hoses connected to the nozzles on the rear bulkhead of the engine compartment - both of them must be hot, otherwise the patency of the tract is broken (blocked hoses, heat exchanger, or heater control damper). Disconnect the hoses and back-flush the heat exchanger. Flush both hoses as well;

- If it is not possible to restore the patency of the heat exchanger by flushing, it should be replaced (see Removal and installation of the heater heat exchanger).

- If the heater fan speed does not correspond to the selected position of the corresponding switch on the system control panel, check the condition of the fuse, connecting wiring, relay, switch and resistor assembly (see Removal and installation of the resistive assembly of the heater fan drive electric motor).

- If there is no air outlet through the deflectors at all, take the following actions:

- Switch on the ignition and activate the heater fan. Press your ear against the deflector and try to hear by ear if the drive motor is working;

- If there are no sounds confirming the correct functioning of the motor, and the resistive assembly is in order, the electric motor should be replaced (see Removal and installation of the heater fan drive electric motor).

1. Moistening of the carpet on the floor under the heater's heat exchanger, or steam escaping through the air duct deflectors indicate heat exchanger leaks. Remove heat exchanger (see Removal and installation of the heater heat exchanger) and replace it with a new one (the heater heat exchanger cannot be repaired).

2. Check the patency of the drain hose coming from the heater/evaporator assembly and routed to the right side of the bulkhead. A blockage in this hose can cause steam to escape from the duct deflectors when the heater is turned on.

Eliminate air conditioning odors

Unpleasant odors that often occur when A/C is turned on are caused by the formation of mold colonies on the evaporator heat exchanger plates. A warm, humid environment creates favorable conditions for the emergence and development of fungal microorganisms.

Access to the evaporator heat exchanger is extremely limited on most models. The procedure for guaranteed complete removal of mold, performed in a car service workshop, is quite laborious, time-consuming and requires the use of strong disinfectants. In principle, sufficiently effective processing can be performed at home by the owner of the car on his own.

1. Specialty aerosol disinfectants designed for servicing air conditioning systems are available from almost any automotive accessory store. It should be remembered that the price of a tool is usually directly proportional to its effectiveness. Switch the system to closed air circulation mode and turn on the heater fan at maximum speed for ten minutes. In order to dry the system, turn on the heating to maximum intensity. Disconnect the electrical wiring from the compressor to prevent it from tripping.

2. The product is usually supplied through a long hose. Remove the resistive assembly of the electric motor of the heater fan drive (see Removal and installation of the resistive assembly of the heater fan drive electric motor), insert the nozzle of the supply nozzle into the resulting hole and move it to the left, pointing at the evaporator heat exchanger. The supply of the product is carried out in accordance with the instructions of its manufacturer. Try to treat the entire surface of the heat exchanger as completely as possible. The duration of each processing cycle and the intervals between series must be indicated on the container label.

Visitor comments