Replacement steel and flexible brake lines can always be purchased at the car manufacturer's authorized service station, as well as in branded car accessories stores.

In no case should you use any tubes as replacements, except for branded ones specially designed for installation in the brake circuit of your car.

When installing brake lines, make sure they are at least 20 mm away from moving or vibrating body, suspension or steering components.

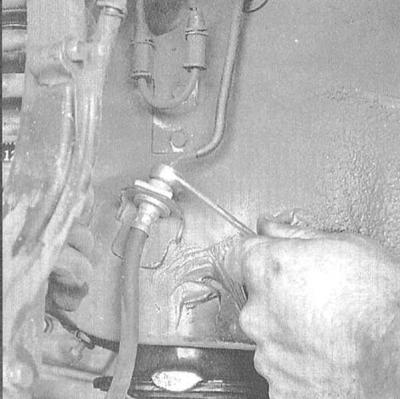

1. Use a special split-head wrench to loosen flexible hose fittings with steel tubing in hydraulic lines.

2. After loosening the nut, remove the retainer and release the brake hose from the support bracket.

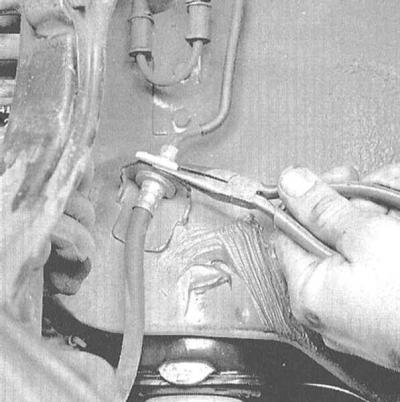

3. To disconnect the brake hose from the caliper, unscrew the hollow bolt of the union connection and discard its old sealing washers - when assembling the washers, they must be replaced without fail.

4. Disconnecting the two hoses is done using conventional open-end wrenches. When joining the units, make sure that the hoses are not twisted.

5. Rigid hydraulic line tubes are usually fixed along their entire length in special clamps. When removing the line, make sure that it is released from all clamps. When installing the lines on the car, do not forget to replace the failed clamps.

6. When replacing the brake lines, make sure that the replacement components are exactly the same size as the old sections removed from the car. Never replace steel pipes with copper ones!

7. When installing steel pipes, make sure that they are securely fixed in all provided brackets, clamps and clamps. Do not run pipes too close to moving suspension and steering components.

8. Having finished installing the new sections of hydraulic lines, check the fluid level in the GTZ reservoir. Make appropriate adjustments if necessary. Bleed the brake system (see Bleeding the brake system). Before starting the operation of the vehicle, make sure that the brakes are working properly.

Visitor comments