Remember that the dust generated during the operation of the brake mechanisms may contain asbestos, which is extremely harmful to human health. Never blow off dust with compressed air or inhale it - wear a protective mask or respirator when servicing mechanisms. Never use gasoline or petroleum-based solvents to clean brake system components - use only branded cleaners or methyl alcohol!

Both brake calipers on the same axle must be changed at the same time.

Removing

1. Set the parking brake, jack up the front of the vehicle and place it on jack stands, remove the relevant front wheel.

2. Remove the cap from the GTZ reservoir, put a plastic film under it and screw it in place - laying the film seals the fit of the cap and prevents fluid from escaping when the flexible brake hose fitting is released. Alternatively, the hose can be clamped with a suitable clamp.

3. Thoroughly clean the hose fitting on the caliper. Turn out a hollow bolt of a socket and remove copper sealing washers, - washers are subject to replacement without fail. Seal the open end of the hose and fitting immediately to prevent dirt from entering the system.

4. Remove the brake pads (see Replacing the pads of the disc brake mechanisms of the front wheels). Remove the support.

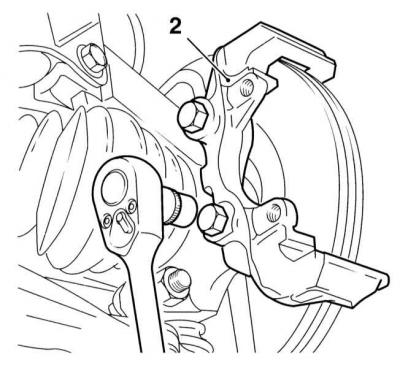

5. On ABS equipped and 2 liter models, if necessary, disconnect the caliper anchor bracket from the hub carriage.

On other models, the bracket is formed by casting the bottom bracket.

Repair

Calipers used on diesel models 1.7 l and 2.0 l are not subject to refurbishment and, in case of malfunction, are replaced as an assembly.

1. Transfer the caliper to the workbench and carefully clean it of dirt and rust using a special cleaner or methyl alcohol.

Never use petroleum-based solvents to clean the brakes!

2. Remove the piston from the caliper cylinder and remove the boot. The piston must be freely removable by hand - if necessary, connect a source of compressed air with a low supply pressure to its fitting (best to use a foot pump) and lay a wooden block between the piston and the caliper bracket.

On models with a solid anchor bracket, the piston is made of plastic.

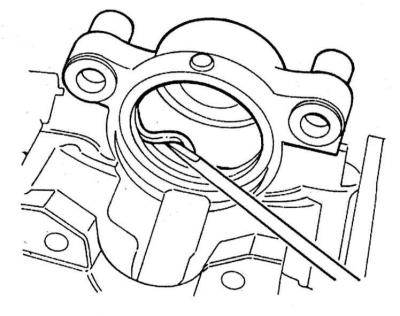

3. Using a plastic applicator, remove the piston cuff from the cylinder - try not to damage the cylinder mirror.

4. Press the guide bushings out of the caliper body.

5. Thoroughly wash all components with a special cleaner and dry them with compressed air - do not forget to wear safety goggles.

6. Replace damaged and worn parts. Carefully examine the condition of the working surfaces of the piston and cylinder, in case of defects, replace the corresponding components. Check the condition of the guide pins and the drillings for their fit - the pins should be free from damage and move easily enough in their seating slots. If you are not sure about the condition of the components, replace them.

7. If you intend to replace the old caliper, prepare all the necessary repair parts. Sealing cuffs and anthers of pistons are subject to replacement without fail.

8. Before assembly, make sure that all components are absolutely clean and dry.

9. Lower the piston and a new sealing cuff into a pure brake liquid, grease a cylinder mirror with it.

10. Use your fingers to fill the cuff into the groove of the cylinder - the use of any tools is fraught with damage to the working surface! Attach a new boot to the piston, turn it with the outer edge up, then fill the piston into the cylinder.

11. Carefully drown the piston in the cylinder, in order to avoid distortions, making rotational and translational movements with it - the outer edge of the anther should fall into the receiving groove on the caliper.

12. Fill the guide bushings into the caliper body.

Installation

1. On 1.7L models with ABS and all 2.0L models install the anchor bracket of the caliper on the hub carriage, screw in the fixing bolts and tighten them with the required force - before installation, the threaded part of the bolts should be lubricated with fixing sealant.

2. Install new copper sealing washers on the hollow bolt of the union connector and attach the hose to the caliper. Make sure that the hose fits correctly in the caliper recess, then tighten the nipple bolt to the required torque.

3. Remove the hose clamp, or remove the polyethylene from under the GTZ reservoir cap and bleed the brake system (see Bleeding the brake system).

It is enough to pump only the circuit whose caliper was removed.

4. Install the wheel, lower the vehicle to the ground and tighten the wheel bolts to the correct torque.

Visitor comments