The replacement of the shoes must be carried out simultaneously on both brake mechanisms. Remember that the dust generated during the operation of the brake mechanisms may contain asbestos, which is extremely harmful to human health. Never blow off dust with compressed air or inhale it - wear a protective mask or respirator when servicing mechanisms. Never use gasoline or petroleum-based solvents to clean brake system components - use only branded cleaners or methyl alcohol!

Simultaneously with the replacement of the brake shoes, their coupling and guide springs must also be replaced, which, as a result of constant cyclic mechanical and thermal loads, stretch / sag over time, stopping developing the required force, which leads to sticking of the brakes and accelerated wear of the drums.

It is correct to disassemble the brake mechanisms one by one - the assembled mechanism, if necessary, can be used as a sample when assembling the dismantled one.

1. Remove the rear brake drum (see Removal, condition check and installation of a brake drum).

2. Sweep away dust accumulated on the surfaces of the brake components (see the warning at the beginning).

3. In several places, measure the thickness of the friction linings of the shoes. If the result of at least one of the measurements exceeds the limit value (see Specifications), all four shoes must be replaced.

4. Oiled shoes must be replaced without fail - first eliminate the cause of the development of the leak.

5. Try to remember the order of installation of the components of the brake mechanism - it will be more correct to make a sketch.

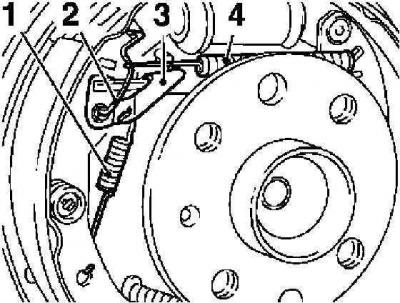

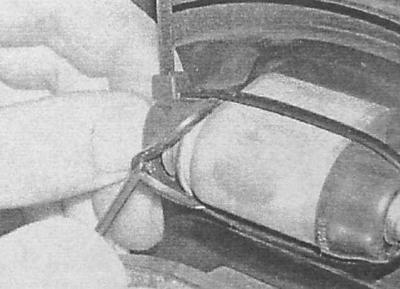

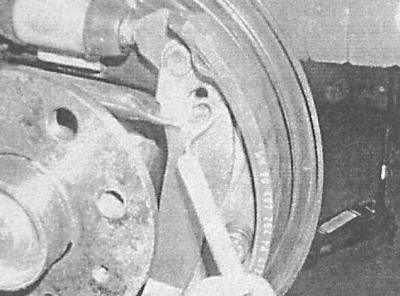

6. Disconnect and remove the top return spring.

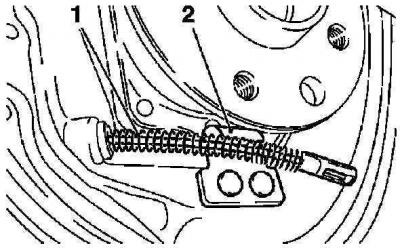

7. Remove the holder and disconnect the adjustment lever assembly with its spring.

1 — Spring of the adjusting lever

2 - Holder

3 - Adjusting lever

4 - Upper coupling spring

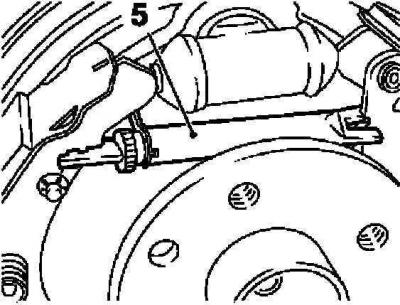

8. Slightly spread the upper ends of the shoes to the sides and remove the adjusting expansion bar installed between them.

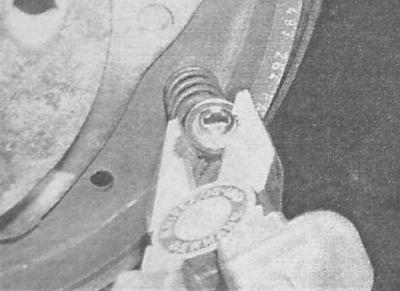

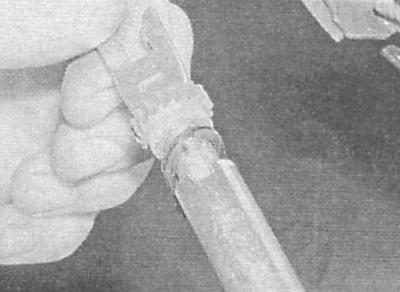

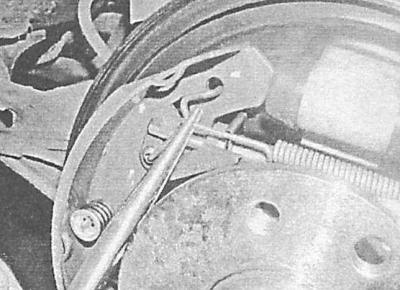

9. Using the special tool KM-346 or suitable pliers, turn the plates of the holders of the guide springs of the shoes so that the latter are released.

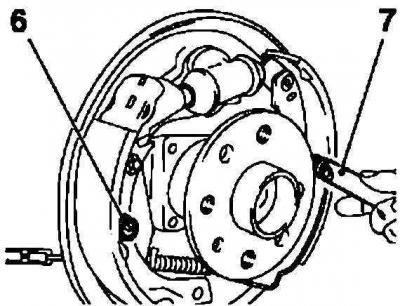

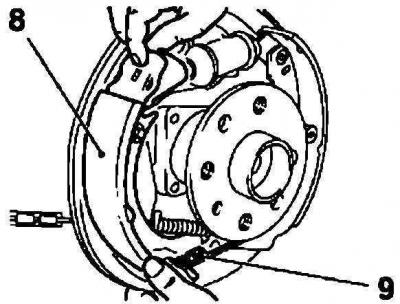

10. Disconnect lower return spring (9) from the rear shoe and remove it complete with the front (8).

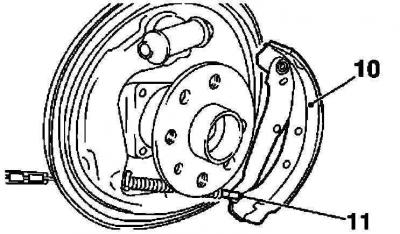

11. Remove the rear pad (10) from the anchor pin and disconnect it from the parking brake cable (11).

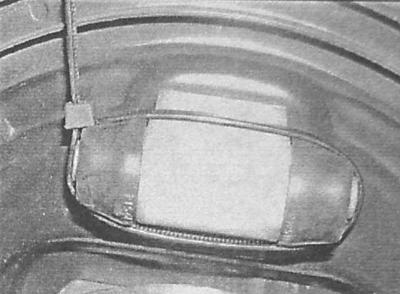

12. Do not press the foot brake pedal with the brake shoes removed - for reliability, pull the pistons of the wheel cylinder with a wire or plastic bandage.

13. If both brake mechanisms are disassembled at the same time, try not to confuse their components - the adjusting strips of the right and left mechanisms are marked with the letters L and R, respectively. Other parts of the left brake mechanism are colored marks, the right one is silver.

14. Disassemble and clean the adjusting bar, lubricate the stem threads with silicone grease.

15. Check the condition of the return springs. Corroded and stretched springs must be replaced.

Installing weak springs can cause the brakes to lock!

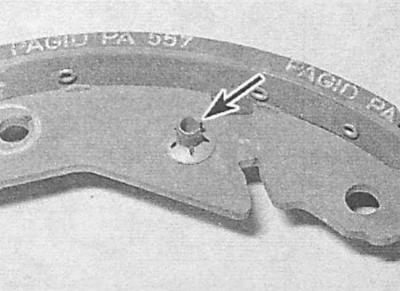

16. If necessary, transfer the parking brake actuator to a new shoe. The lever is riveted to the shoe, or fastened with a pin - the rivet should be drilled out. It may be necessary to rearrange the axis of the adjusting lever with a lock from the old shoe to the new one.

17. Remove the rubber boots from the wheel cylinder and check it for signs of leaks. Check the freedom of movement of both pistons, if necessary, carry out appropriate reconditioning (see Removal, refurbishment and installation of front wheel disc brake calipers).

18. Before installation, clean the brake shield. Lubricate the surfaces of the shield in contact with the moving components of the brake mechanism, as well as the pistons of the wheel cylinder with high-temperature grease - try to prevent grease from getting on the friction linings.

19. Hook the tip of the handbrake cable to the hook on the shoe lever - make sure that the cable gets into the guide on the brake shield. Install the rear shoe on the brake shield.

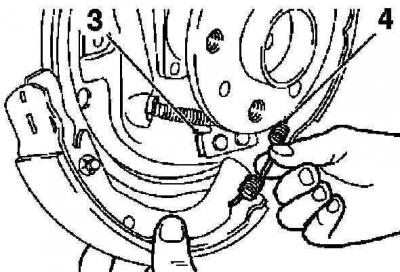

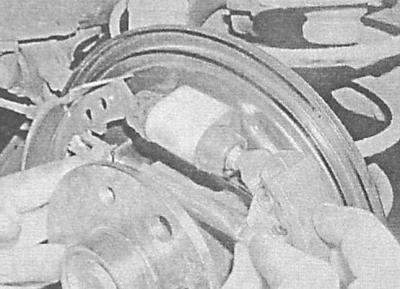

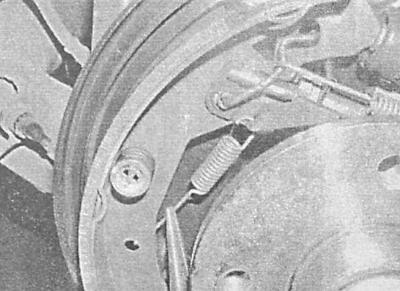

20. Install the anchor pin and rear shoe guide spring and secure the components with the retainer.

21. Connect the lower return spring to the rear shoe, then hook the front shoe onto it and install the latter in its regular place, engaging it with the guide.

3 - Guide

4 - Lower coupling spring

22. Install the guide spring and fix it with the holder.

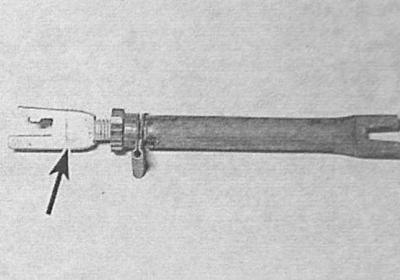

23. Screw the threaded rod all the way into the forked part of the adjusting expansion bar, shortening the latter to the limit. Unscrew the gear wheel half a turn and check its freedom of rotation.

24. Install the bar between the shoes, with the long end towards the rear shoe.

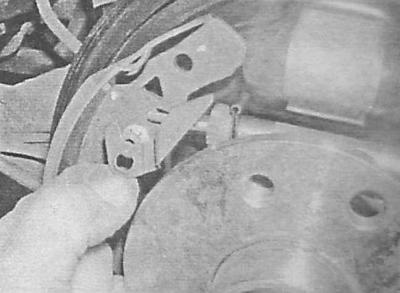

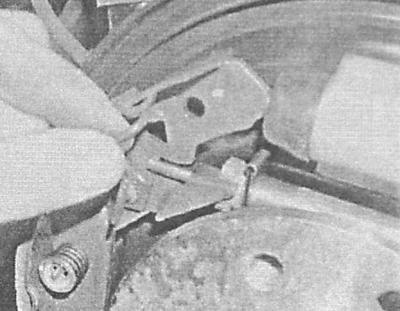

25. Hook the adjuster lever onto the ratchet wheel of the expander bar.

26. Then put the lever on the axle and fix it in this position with the holder.

27. Remove the binding from the pistons of the wheel cylinder. Make sure the shoes are properly aligned with the pistons and install the top return spring.

A - Connecting the upper return spring to the rear shoe

B - Connecting the top return spring to the front shoe

A.

B.

28. Install the adjuster spring.

29. Make sure that the stop pin of the parking brake actuating lever rests against the rib of the shoe and install the brake drum in place (see Removal, condition check and installation of a brake drum).

30. In the same manner, service the second brake

31. Having installed both drums, with the parking brake fully released, depress the foot brake pedal 20-25 times, asking an assistant to listen to the operation of the adjusting mechanisms.

32. Adjust the parking brake actuator (see Parking brake actuator adjustment).

33. In conclusion, check the level of brake fluid in the GTZ reservoir, if necessary, make the appropriate adjustment (see chapter Current service).

Full braking efficiency after changing the shoes is achieved only after 100-150 km of run - avoid sudden braking!

Visitor comments