To prevent the vehicle from pulling to the side during braking, the brake pads must be replaced on both front/rear brakes at the same time. Remember that the dust generated during the operation of the brake mechanisms may contain asbestos, which is extremely harmful to human health. Never blow off dust with compressed air or inhale it - wear a protective mask or respirator when servicing mechanisms. Never use gasoline or petroleum-based solvents to clean brake system components - use only branded cleaners or methyl alcohol!

1. Support the front wheels with wheel chocks, jack up the rear of the vehicle and support it on jack stands. Remove both rear wheels.

2. Fully release the parking brake and loosen the drive cable by loosening the adjusting nut.

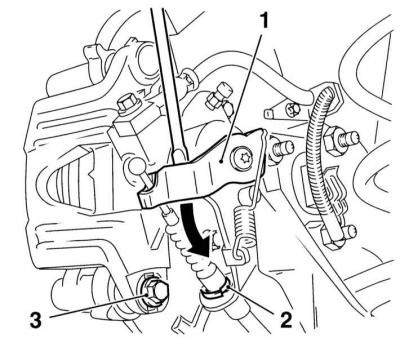

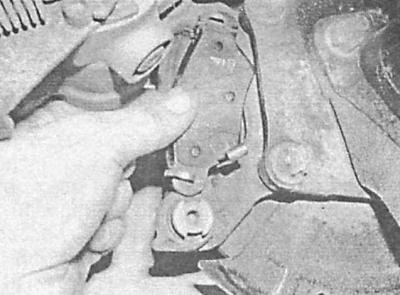

3. Using a screwdriver, press the actuating lever on the rear wheel brake caliper and disconnect the tip of the cable from it, release the latch and release the cable from the support bracket.

4. Turn out the bottom bolt of fastening of a support, holding the directing pin from turning curly brace. Remove the curly brace.

1 - Executive lever

2 - Cable fastener in the support bracket

3 — the Lower bolt of fastening of a support

5. Turn the caliper up on the axis of the upper guide and remove the pads.

A - Removing the outer pad

B - Removing the inner pad

A.

B.

6. Sweep away dust accumulated on the surfaces of the brake components (see the warning at the beginning). Wipe the caliper and piston face with a clean rag. Remove rust from the edge of the brake disc.

7. Measure the thickness of each pad, not including the metal backing. If any pad is damaged or worn beyond the allowable limit (see Specifications), replace the entire set of pads, both front wheels. Oily pads must be replaced without fail - first eliminate the cause of the leak.

8. If the condition of the brake pads is found to be satisfactory, carefully clean them of dirt with a soft wire brush, paying special attention to the back and sides. Clean the grooves in the friction linings, completely removing foreign inclusions from them. Clean the pad seats in the caliper and anchor bracket.

9. The guide pins must move freely in the caliper bushings. Lubricate the backs of the pads with copper grease. Check the condition of the anther installed on the piston, inspect the piston for signs of brake fluid leakage, corrosion and mechanical damage. Make necessary repairs if necessary (see Removal, refurbishment and installation of front wheel disc brake calipers). Replace defective components.

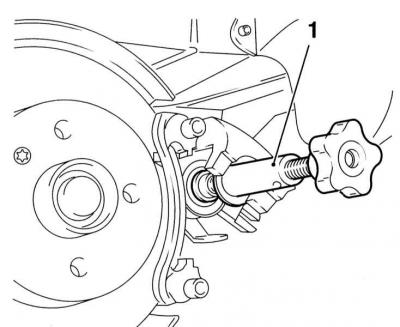

10. When installing new pads, the piston must be drowned in the caliper cylinder in order to release it for installing thicker new pads - the cutout on the piston must be aligned with the protrusion on the remove. The piston is pressed using a special tool (1), although a suitable clamp or wooden lever will work just as effectively. If the GTZ reservoir is not filled to the top, squeezing the piston should not cause brake fluid to leak out of it, however, it would be wise to check its level first - if necessary, pump out the excess.

Pressing the piston is associated with a risk of damage to the sealing collar. The compilers of this Guide recommend pinching the brake hose with a clamp and bleed the fluid through the bleeder fitting, after releasing it half a turn.

11. Turning the piston, achieve the alignment of the cutout in its end surface with the protrusion on the caliper.

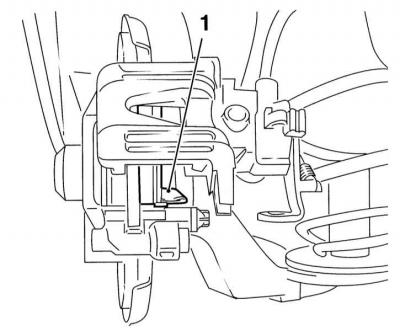

12. Turn the caliper up, install new pads in the anchor bracket with friction linings to the disc. Acoustic signal wear spring (1) installed on the inner block.

13. Lower the caliper onto the pads. Clean the bottom bolt threads with a wire brush, or «drive away» her lerkoy. Lightly lubricate the threaded part of the bolt with locking compound, then screw in the bolt and tighten it to the required torque while holding the drive pin from turning with an open-end wrench.

14. Place the handbrake drive cable into the caliper bracket and secure with a brace.

15. Wring out the executive lever and connect to it a tip of a cable.

16. Depress the foot brake pedal several times until you feel «hardness» her move.

17. In the same manner, replace the brake pads on the opposite wheel.

18. Adjust parking brake cable (see Parking brake actuator adjustment).

19. Install the wheels, lower the vehicle to the ground and tighten the wheel bolts to specification.

20. Check brake fluid level, correct if necessary (see chapter Current service).

Visitor comments