Engines 1.4, 1.6 and 1.8 l

See Removal and installation of the oil pan - models with a cast pallet.

Please note that on models 1.4 and 1.6 l, the pan is installed through a gasket, which must be replaced without fail during assembly.

When installed on 1.4 and 1.6 l models, the sealant is applied to the mating surface of the cylinder block in the areas where the oil pump housing and the rear main bearing cover are docked.

On 1.8 l models, a pad of sealant with a thickness of about 2.5 mm should be applied to the entire mating surface of the mating flange; at the docking site of the fifth main bearing cap, the pad thickness should be increased to 3.5 mm.

Engines 2.0 l

Removing

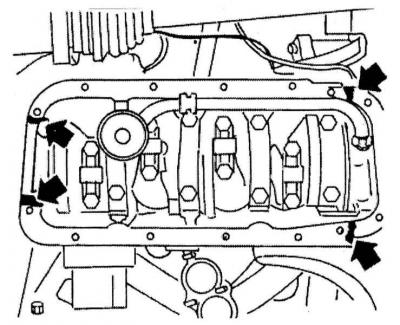

1. Follow the procedures - see Removal and installation of the oil pan — Withdrawal, - after disconnecting the wiring from the oil level sensor, release the lock and push the sensor inside the sump.

2. Turn out bolts of fastening of the bottom section of the pallet to the main cast section. Remove the bottom section and its seal, being careful not to damage the sensor wiring.

3. To remove the main section of the sump, you must first remove the oil filter (see chapter Current service).

When installing the filter, it would be wise to replace it.

4. On models with manual transmission, disconnect the right drive shaft from the box (see chapter Clutch and drive shafts). To ensure adequate access, remove the right shaft bearing flange from the gearbox housing.

5. Turn out bolts of fastening of a landing flange of the pallet to a case of transmission.

6. Turn out bolts of fastening of an oil pickup to the bridge of covers of radical bearings and to the oil pump.

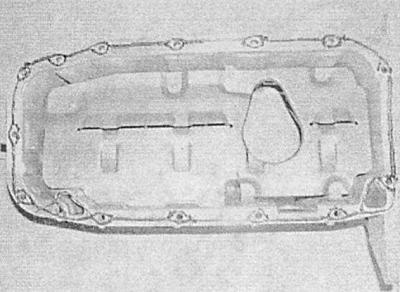

7. Loosen evenly in several steps, then remove the bolts of the main sump section to the cylinder block/oil pump. If pallet «stuck» and does not lend itself, lightly tap it from the sides with a soft-faced hammer. Lower the pan and remove it from under the vehicle complete with oil pickup. Remove and discard the sealing gasket - the gasket must be replaced during reassembly without fail.

Installation

The pan mounting bolts must be replaced without fail.

1. Thoroughly clean the mating surfaces of the sump, oil intake and block, completely removing traces of dirt and oil from them. Clean the threaded holes in the pan from traces of the old anaerobic sealant.

2. Replace the oil pickup O-ring.

3. Make sure that the mating surfaces of the main section of the sump and cylinder block are absolutely clean and dry, remove traces of anaerobic sealant from the threaded part of the mounting bolts.

4. Apply a layer of sealant to the mating surface of the cylinder block around the oil pump housing and rear main bearing cap.

5. Lay a new gasket on the main pan section and apply a few drops of anaerobic sealant to the threads of the mounting bolts.

6. Press the pan assembly with the oil pickup and sealing gasket to the block and install the mounting bolts. Moving from the center to the edges in a diagonal sequence, gradually tighten the casting mounting bolts to the required torque. Also, with the required force, tighten the oil intake mounting bolts.

7. Tighten with the required effort the bolts of the flange of the main section of the pallet to the transmission case.

8. Install the exhaust pipe (see chapter Power and exhaust systems). Install the driveshaft bearing flange.

9. Install the drive shaft (see chapter Clutch and drive shafts).

10. Make sure that the mating surfaces of the lower and main sections of the sump are absolutely clean and dry, lay a new gasket on the lower section and press the assembly to the main assembly - do not forget to install a new o-ring on the oil level sensor connector and put the connector in the main section of the sump.

11. Install new sump bath bolts, then, moving in a diagonal sequence from the center outwards, tighten the bolts to first stage torque. Then tighten the fasteners to the stage 2 corner in the same order.

12. Install a new oil filter.

13. Connect the electrical wiring to the oil level sensor.

14. Lower the car and fill with fresh engine oil (see chapter Current service).

Visitor comments