2. After returning the head from the workshop, valves with related elements will already be installed in it. In this case, you should omit the procedures of the next two paragraphs and proceed directly to the actions described below (see item 5).

3. On diesel engines lubricate the valve stems with liquid oil and thread them into their guide bushings.

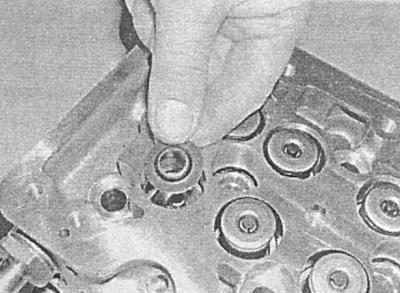

4. Install valve spring seats.

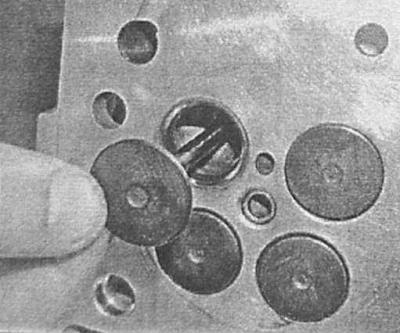

5. On gasoline engines install the spring seats, then, after dipping them in clean engine oil, place the oil deflector cap on the guide bushing of the first valve - proceed very carefully, trying not to damage the sealing edges of the cap. The cap is pressed onto the sleeve using a cylindrical mandrel, which can be a replaceable end head of the appropriate size, or a pipe section of a suitable diameter.

6. On diesel engines repeat the procedures of the previous paragraph (the oil cap is first placed on the valve stem, then on the guide sleeve).

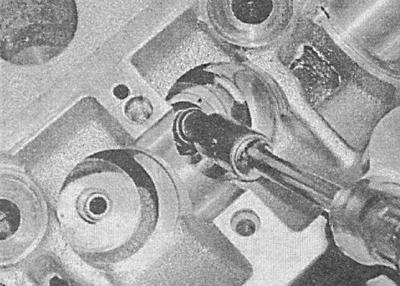

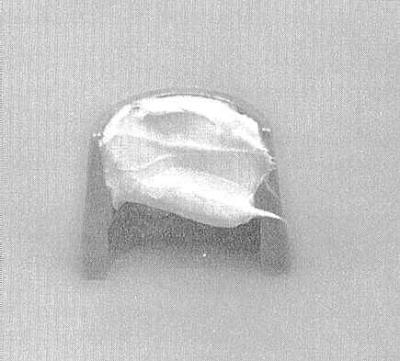

7. Using a special tool, compress the spring by lowering the plate, then install the crackers of the split lock into the opened upper groove on the valve stem. For the purpose of temporary fixation of the crackers before releasing the tool, lubricate them from the inside with grease. Slowly release the spring and check that the shims are securely seated.

Usually springs are installed in coils with a reduced pitch to the head.

8. On DOHC engines Install the valve lifters and camshafts.

9. On SOHC engines install the camshaft, hydraulic pusher assemblies and valve levers.

10. Make sure that the old components removed from the head for further use are installed strictly in their original places.

Visitor comments