SOHC engines

New pipe nuts are required during installation.

1. Relieve the pressure in the supply system (see Relieving pressure in the power supply system of gasoline engines). Disconnect the negative cable from the battery.

2. Remove the accessory drive belt and empty the cooling system (see chapter Current service).

3. Remove the air cleaner and intake ducts (see Removal and installation of components of an inlet air path).

4. Disconnect the vacuum hoses and crankcase ventilation hoses from the throttle body cover, unscrew the fixing screws and remove the cover with the sealing ring from the throttle body.

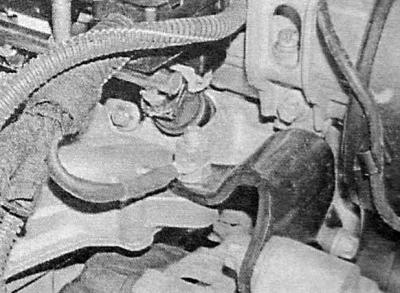

5. Disconnect the wiring from the TPS sensor, idle speed stepper motor, fuel injection injector, ECT sensor, EGR valve, fuel tank vent valve, and MAP sensor. Release the wiring harnesses from the intermediate clamps - try to remember the order of their installation. Remove the electrical wiring routing trough from the timing cover and move it away from the intake manifold.

6. Turn out bolts of fastening of an arm of fastening of the generator to the inlet pipeline. Release the generator from the lug and tilt it back.

7. Give the nipple nuts and disconnect the fuel hoses from the throttle body, - when releasing the nuts, hold the connector from turning with the second open-end wrench.

8. Disconnect the drive rod from the throttle shaft, unscrew the two fixing bolts and remove the support bracket from the pipeline together with the cable sheath fixed in it.

9. Disconnect the vacuum hoses and crankcase ventilation hoses from the throttle body, try to remember the installation position of the components. Disconnect the vacuum hose from the fuel tank vent valve.

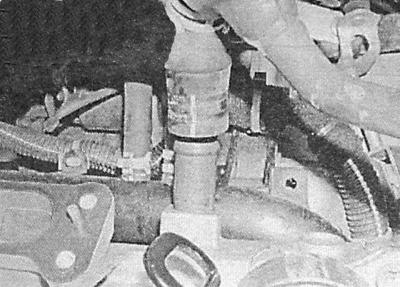

10. Loosen the mounting clamp and disconnect the coolant hose from the rear of the intake manifold.

11. Release a clamp and remove a hose of a servo drive of the vacuum amplifier of brakes from the pipeline.

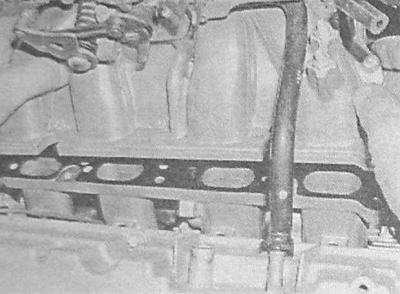

12. Make sure that all communication lines are disconnected and nothing prevents the removal of the pipeline. Turn out nuts of fastening of the pipeline.

13. Remove the pipeline from the engine and remove the sealing gasket from it - try to remember the installation position of the gasket.

14. Installation is carried out in the reverse order. Pay attention to the following points:

- Before installation, check the condition of the pipeline fixing pins, - replace defective pins. Use new pipeline nuts;

- Before installation, make sure that the mating surfaces of the pipeline and the unit are absolutely clean and dry, do not forget to replace the sealing gasket. Tighten the fixing nuts with the required force in several stages - try to ensure complete uniformity;

- Make sure that all communication lines are connected correctly and securely fixed;

- Make sure that the union nuts of the fuel lines and the vacuum brake booster hose are tightened to the required torque.

15. Finally, install the accessory drive belt and charge the cooling system (see chapter Current service).

Engines 1.4 and 1.6 l DOHC

If only the rear of the piping is to be removed, follow the procedures in paragraphs 1 to 15.

1. Remove the oil filler cap, remove the fixing screws and remove the engine guard. Screw the oil filler cap into place. Empty the cooling system (see chapter Current service).

2. Remove the air cleaner with intake duct (see Removal and installation of components of an inlet air path).

3. Overcoming the resistance of the spring, turn the tensioner by the central bolt and remove the auxiliary drive belt from the pulleys.

4. Turn out fixing bolts and remove a basic arm of the generator from the right party of the pipeline.

5. Loosen the lower alternator mounting bolt and tilt the alternator back.

6. Remove the support arm installed between the inlet pipeline and the cylinder block.

7. Disconnect the crankcase ventilation hose from the gas distribution mechanism cover.

8. Remove the fuel line with injection injectors (see Removal and installation of components of systems of distributed fuel injection Multec-S and Simtec-70).

9. Disconnect the throttle cable from the throttle body and release it from the support bracket (see Removing, installing and adjusting the throttle cable - petrol models).

10. Disconnect the wiring from the idle speed control stepper motor and TPS sensor.

11. Loosen the clamp and disconnect the brake booster servo hose from the pipeline.

12. Disconnect the vacuum hose from the MAP sensor.

13. Disconnect the fuel tank ventilation hose from the throttle body.

14. Loosen the clamps and disconnect the cooling path hoses from the throttle body.

15. Turn out fixing bolts and remove the pipeline from a landing flange. It is not recommended to disassemble the pipeline.

16. To remove the landing flange, disconnect the cooling path hose from its left side.

17. Turn out fixing nuts and remove a flange from a head of cylinders, - for removal of a flange from hairpins it is necessary to press down a hose of a cooling path a little.

18. Installation is carried out in the reverse order. Pay attention to the following points:

- Before installation, check the condition of the pipeline fastening studs, - replace damaged elements;

- Before installation, make sure that the mating surfaces are absolutely clean and dry, do not forget to replace the gasket. If the flange was removed, make sure that the nuts of its fastening are tightened evenly and with the required force;

- Install the back of the manifold, don't forget to replace the gasket. Make sure that the fixing bolts are tightened to the required torque;

- Restore the original connection of all communication lines, - make sure that they are connected correctly and securely fixed;

- Make sure that the nuts of the union connections are tightened with the required force;

19. Finally, charge the cooling system (see chapter Current service) and throttle cable adjustment (see Removing, installing and adjusting the throttle cable - petrol models).

Engines 1.8 and 2.0 l

New pipe nuts are required during installation.

1. Remove the accessory drive belt and empty the cooling system (see chapter Current service).

2. Relieve pressure in the supply system (see Relieving pressure in the power supply system of gasoline engines). Disconnect the negative cable from the battery.

3. Remove the oil filler cap, unscrew the fixing screws and remove the engine guard.

4. Disconnect the electrical wiring from the MAF sensor.

5. Release fixing collars, disconnect an inlet air line in gathering with the MAF gauge. On Zafira models remove the sealing strip of the engine compartment and the fairing cover installed under the lower edge of the windshield. In order to provide access to the intake air duct, give the fixing nuts / bolts and remove the top cover of the front panel.

6. Release the latch and disconnect the gas cable from the hinge, release the cable from the support bracket.

On models equipped with an engine management system, remove the tempostat drive cable - the cable is attached to the hinge with a spring bracket.

7. Loosen the clamps and disconnect the crankcase ventilation hoses from the timing cover and throttle body.

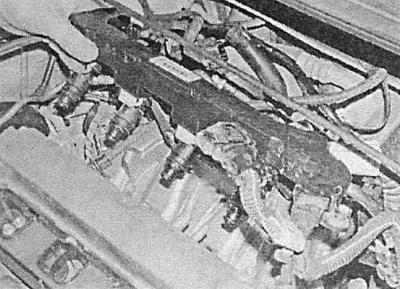

8. Disconnect the cooling path hoses from the throttle body. Disconnect the cooling system pipe from the timing cover and the left end of the intake manifold and take it to the side.

9. Disconnect the fuel tank ventilation hose from the throttle body.

10. On engines 2.0 l Disconnect the wiring from the TPS sensor and idle speed control valve. On engines 1.8 l Disconnect the wiring from the throttle controller.

11. Disconnect all remaining hoses from the throttle body - try to remember the installation position of the components.

12. On engines 1.8 l Loosen the lower alternator mounting bolt and remove the upper mounting bolt. Turn out fixing bolts and separate a basic arm of the generator from the inlet pipeline and a head of cylinders. On engines 2.0 l remove the alternator support bracket from the inlet pipeline, also remove the generator mounting bracket to the cooling system flange and inlet pipeline. Tilt the generator back.

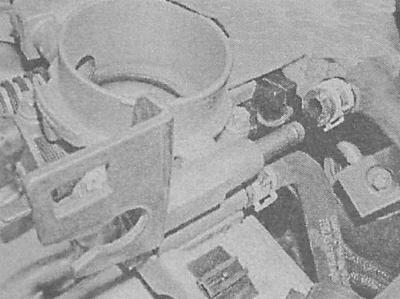

13. Remove the mounting bolts and remove the support bracket from the pipeline base.

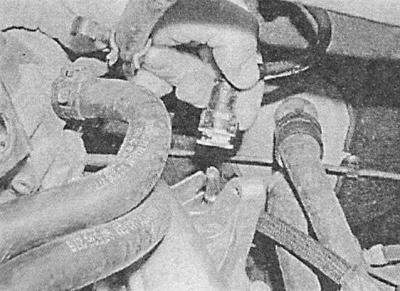

14. On engines 1.8 l loosen the nipple nut and disconnect the fuel line from the fuel line, - when releasing the nipple nut, hold the connector from turning with the second wrench. On engines 2.0 l Disconnect the fuel return line from the pressure regulator, disconnect the fuel supply line from the fuel line.

15. Disconnect the wiring from the crankshaft position sensor (CKP) and the solenoid valve-switching of the inlet pipeline, also disconnect the contact connectors of all harnesses laid in the route chute installed above the injection injectors. Turn out the left bolt of fastening of a trench. On engines 2.0 l remove the spark plug cap and disconnect the wiring from the camshaft position sensor (CMP).

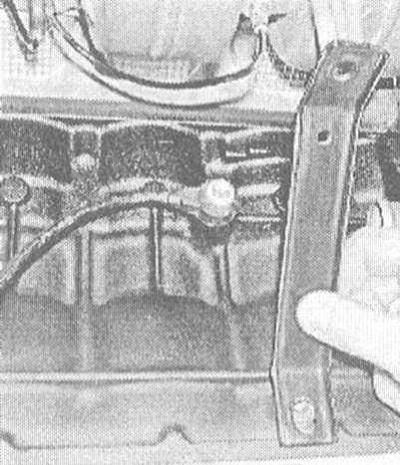

16. Turn out bolts of fastening of a fuel highway to the inlet pipeline, remove the highway in gathering with injectors and an electroconducting gutter.

17. Disconnect from the inlet pipeline a hose of the servo drive of the vacuum amplifier of brakes. Disconnect all remaining vacuum / air hoses from the pipeline - try to remember the installation position of the components.

18. Disconnect the heater hose from the inlet pipeline.

19. Turn out fixing bolts and remove a back lug of transportation of the engine from a head of cylinders.

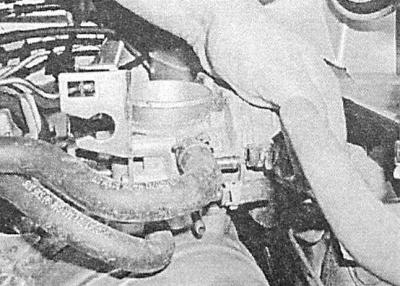

20. Loosen the TORX head screws (engines 1.8 l) and nuts (engines 2.0 l), and remove the throttle body from the intake manifold.

21. On equipped manual transmission models 2.0 l release the connector and disconnect the tube from the clutch hydraulic cylinder. On engines 1.8 l disconnect the remaining electrical wiring, remove the three mounting bolts and remove from the ECM inlet pipe.

22. Turn out fixing bolts/nuts and remove the pipeline from the engine.

23. Remove and discard gasket.

Do not attempt to disassemble the intake manifold - only diaphragm and solenoid valve assemblies are supplied to the spare parts market individually.

24. Installation is carried out in the reverse order.

- Before installation, check the condition of the pipeline fastening studs, - replace damaged elements;

- Before installation, make sure that the mating surfaces are absolutely clean and dry, do not forget to replace the gasket. Make sure that the fixing bolts are tightened to the required torque;

- Restore the original connection of all communication lines, - make sure that they are connected correctly and securely fixed;

- On models with a manual transmission, check the clutch for proper operation, if necessary, bleed the hydraulic path (see chapter Clutch and drive shafts).

- Make sure that the union nuts are tightened to the required torque.

25. Finally, install the accessory drive belt, refuel the cooling system (see chapter Current service) and throttle cable adjustment (see Removing, installing and adjusting the throttle cable - petrol models).

Visitor comments