Common parameters

A complete list of engines used to complete the Opel Astra-G / Zafira models

Gasoline engines

Astra-G

|

Working volume (l) |

code designation

|

Type

|

Developed power

|

Year of issue |

|

1.2 |

X12XE

|

1.2i 16V DOHC

|

kW (hp)

|

03/1988- |

|

Z12XE

|

1.2i 16V DOHC

|

48 (65)

|

sep.00 | |

|

1.4 |

X14XE

|

1.4i 16V DOHC

|

55 (75)

|

03/1998- |

|

Z14XE

|

1.4i 16V DOHC

|

66 (89)

|

09/2000- | |

|

1.6 |

X16SZR

|

1.6i SOHC

|

66 (89)

|

03/1998-08/2000 |

|

X16XEL

|

1.6i 16V DOHC

|

55 (75)

|

03/1998-08/2000 | |

|

C16SEL

|

1.6i SOHC

|

74 (100)

|

09/1998- | |

|

C16SEL

|

1.6i CS, CD,

|

74 (100)

|

10/1999- | |

|

Z16SE

|

1.6i SOHC

|

74 (100)

|

09/2000- | |

|

Z16XE

|

1.6i 16V DOHC

|

62 (85)

|

| |

|

Z16XE

|

Cabrio 1.6i 1 DOHC

|

74 (100)

|

03/2001- | |

|

1.8

|

X18XE1

|

1.8i 16V DOHC

|

74 (100)

|

03/1998-08/2000 |

|

X18XE1

|

Coupe 1.8i 16V DOHC

|

85 (115)

|

09/1999-08/2000 | |

|

X18XE1

|

1.8i CDE,

|

85 (115)

|

Oct.99 | |

|

Z18XE

|

Coupe 1.8i 16V DOHC

|

85 (115)

|

09/2000- | |

|

Z18XE

|

1.8i 16V DOHC

|

92 (125)

|

09/2000- | |

|

Z18XEL

|

Coupe 1.8i DOHC

|

92 (125)

|

03/2001- | |

|

Z18XE

|

Cabrio 1.8i 1 DOHC

|

85 (115)

|

03/2001- | |

|

2.0

|

X20XEV

|

2.0i 16V DOHC

|

92 (125)

|

03/1988- |

|

C20SEL

|

2.0i CDX, CSX DOHC

|

100 (136)

|

10/1999- | |

|

Z20XER

|

2.0i 16V DOHC

|

95 (129)

|

09/2000- | |

|

Z20LET

|

Coupe 2.0i 16V DOHC

|

118 (160)

|

12/2000- | |

|

2.2

|

Z22SE

|

2.2i 16V DOHC

|

141 (192)

|

09/2000- |

|

Z22SE

|

Coupe 2.2i 16V DOHC

|

108 (147)

|

12/2000- | |

|

Z22SE

|

Cabrio 2.2i 1 DOHC

|

108 (147)

|

03/2001- |

Zafira

|

Working volume (l) |

code designation

|

Type

|

Developed power

|

Year of issue |

|

1.6 |

X16XEL

|

1.6i 16V DOHC

|

74 (100)

|

03/1999-08/2000 |

|

Z16XEL

|

1.6i 16V DOHC

|

74 (100)

|

09/2000- | |

|

CNG (Gasmotor)

|

1.6i 16V

|

71 (96)

|

09/2001- | |

|

1.8

|

X18XE1

|

1.8i 16V DOHC

|

85 (115)

|

03/1999-08/2000 |

|

Z18XE

|

1.8i 16V DOHC

|

92 (125)

|

09/2000- | |

|

2.0 |

Z20

|

2.0 16V Turbo

|

141 (192)

|

09/2001- |

|

2.1 |

Z22SE

|

2.2 16V DOHC

|

108 (147)

|

09/2000- |

Diesel engines

Astra-G

|

Working volume (l) |

code designation

|

Type

|

Developed power

|

Year of issue |

|

1.7 |

X17DTL

|

1.7DTL SOHC-Turbo

|

50 (75)

|

03/1998-08/2000 |

|

Y17DT

|

1.7DT DOHC

|

55 (75)

|

09/2000- | |

|

Y17DIT

|

1.7DIT DOHC-Turbo

|

55 (75)

|

08/2000- | |

|

2.0 |

X20DTL

|

2.0DTL 16V SOHC-Turbo

|

60 (82)

|

03/1998-08/2000 |

|

Y20DTL

|

2.0DTL 16V SOHC-Turbo

|

60 (82)

|

09/2000- | |

|

Y20DTH

|

2.0DTH 16V SOHC-Turbo

|

74 (100)

|

09/2000- | |

|

2.2 |

Y2.2DTR

|

2.2DTR

|

-

|

- |

Zafira

|

Working volume (l) |

code designation

|

Type

|

Developed power

|

Year of issue |

|

2.0 |

X20DTL

|

2.0DTL 16V SOHC-Turbo

|

60 (82)

|

03/1998-08/2000 |

|

Y20DTL

|

2.0DTL 16V SOHC-Turbo

|

74 (100)

|

09/2000- | |

| 2.2 |

Y2.2DTR

|

2.2DTR

|

-

|

- |

Engine designations covered in this manual

Gasoline engines

|

8-valve 1.6L SOHC engine |

X16SZR |

|

16-valve DOHC engines |

|

|

X14XE |

|

X16XEL |

|

X18XE1 |

|

X20XEV |

Diesel engines

|

1.7L 8-valve SOHC engine with low pressure turbocharged |

X17DTL |

|

1.7L DOHC 16-valve non-turbo engine |

Y17DT |

|

2.0L 16-valve DOHC low pressure turbo engine |

X20DTL/Y20DTL |

|

2.0L 16-valve DOHC engine with high-pressure turbocharging

|

Y20DTH |

Main performance characteristics

Cylinder displacement, cm3

|

Gasoline engines |

|

|

1.2 l

|

1199 |

|

1.4 l

|

1389 |

|

1.6 l

|

1598 |

|

1.8 l

|

1796 |

|

2.0 l

|

1998 |

|

2.2 l

|

2198 |

|

Diesel engines |

|

|

1.7 l

|

1686 |

|

2.0 l

|

1995 |

|

2.2 l

|

2172 |

Engine power, kW (at rpm) /Torque, Nm (at rpm)

|

X12XE

|

48 (5600) /110 (4000) |

|

Z12XE

|

55 (5600) /110 (4000) |

|

Z14XE/X14XE

|

66 (6000) /125 (4000) |

|

Z16SE/X16SE

|

62 (5400) /138 (2600) |

|

Z16XE/X16XE

|

74 (6000) /150 (3600) |

|

Z16XEP/X16XEP

|

76 (6000) /147 (3600) |

|

Z18XE/X18XE

|

92 (5600) /170 (3800) |

|

Z20LET/X20LET

|

141 (5400) /250 (1950—5300) |

|

X20XEV

|

100 (5600) /188 (3400) |

|

X20XER

|

118 (6800) /188 (4300) |

|

Z22SE/X22SE

|

108 (5800) /203 (4000) |

|

Y17DT/X17DT

|

55 (4400) /165 (1800—3000) |

|

Y17DT (ECO)

|

55 (4400) /165 (1800—3000) |

|

X20DTL/Y20DTL

|

60 (4300) /185 (1800—2750) |

|

Y20DTH

|

74 (4300) /230 (1950—2500) |

|

Y22DTR

|

92 (4000) /280 (1500—2750) |

Compression ratio

|

Z12XE/X12XE

|

10.1:1 |

|

Z14XE/X14XE

|

10.5:1 |

|

Х16SZR

|

9.6:1 |

|

Z16SE/X16SE

|

9.6:1 |

|

Z16XE/X16XE

|

10.5:1 |

|

Z16XEP/X16XEP

|

10.5:1 |

|

Z18XE/X18XE

|

10.5:1 |

|

Z20LET/X20LET

|

8.8:1 |

|

X20XEV

|

10.8:1 |

|

X20XER

|

10.8:1 |

|

Z22SE/X22SE

|

10.0:1 |

|

Y17DT/X17DT

|

18.4:1 |

|

Y17DT (ECO)

|

18.4:1 |

|

X20DTL/Y20DTL

|

18.5:1 |

|

Y20DTH

|

18.5:1 |

|

Y22DTR

|

18.5:1 |

Compression pressure

The data are given only for the engines considered in this Manual.

|

Gasoline engines |

|

|

Rated value (all covered in the Guide

engines), bar

|

12—15 |

|

Maximum allowable difference between cylinders (all considered

in the engine manual), bar

|

1 |

|

Diesel engines |

|

|

Nominal value, bar | |

|

12—15 |

|

26—30 |

|

25—28 |

|

Maximum allowable difference between cylinders, bar

| |

|

1 |

|

1 |

|

1 |

Maximum allowable speed, rpm

|

Z12XE/X12XE

|

6250 |

|

Z14XE/X14XE

|

6400 |

|

Z16SE/X16SE

|

6000 |

|

Z16XE/X16XE

|

6400 |

|

Z16XEP/X16XEP

|

6400 |

|

Z18XE/X18XE

|

6400 |

|

Z20LET/X20LET

|

6400 |

|

X20XEV

|

Data not provided |

|

X20XER

|

Data not provided |

|

Z22SE/X22SE

|

6500 |

|

Y17DT/X17DT

|

5100—5300 |

|

Y17DT (ECO)

|

5200 |

|

X20DTL/Y20DTL

|

4750 |

|

Y20DTH

|

4950—5050 |

|

Y22DTR

|

4920—5080 |

Arrangement / number of cylinders / number of valves per cylinder

|

SOHC engines |

row/4/2 |

|

DOHC engines |

row/4/4 |

The order of operation of the cylinders

1-3-4-2 (the first cylinder is located on the timing side)

Normal direction of rotation of the crankshaft

Clockwise

Cylinder diameter, mm

|

Z12XE/X12XE

|

72.5 |

|

Z14XE/X14XE

|

77.6 |

|

Z16SE/X16SE

|

79.0 |

|

Z16XE/X16XE

|

79.0 |

|

Z16XEP/X16XEP

|

79.0 |

|

Z18XE/X18XE

|

80.5 |

|

Z20LET/X20LET

|

86.0 |

|

X20XEV

|

86.0 |

|

X20XER

|

86.0 |

|

Z22SE/X22SE

|

86.0 |

|

Y17DT/X17DT

|

79.0 |

|

Y17DT (ECO)

|

79.0 |

|

X20DTL/Y20DTL

|

84.0 |

|

Y20DTH

|

84.0 |

|

Y22DTR

|

84.0 |

Piston stroke, mm

|

Z12XE/X12XE

|

72.6 |

|

Z14XE/X14XE

|

73.4 |

|

Z16SE/X16SE

|

81.5 |

|

Z16XE/X16XE

|

81.5 |

|

Z16XEP/X16XEP

|

81.5 |

|

Z18XE/X18XE

|

88.5 |

|

Z20LET/X20LET

|

86.0 |

|

X20XEV

|

86.0 |

|

X20XER

|

86.0 |

|

Z22SE/X22SE

|

94.5 |

|

Y17DT/X17DT

|

86.0 |

|

Y17DT (ECO)

|

86.0 |

|

X20DTL/Y20DTL

|

90.0 |

|

Y20DTH

|

90.0 |

|

Y22DTR

|

98.0 |

Operating parameters of engines

Operating parameters are given only for the engines covered in this manual (see above).

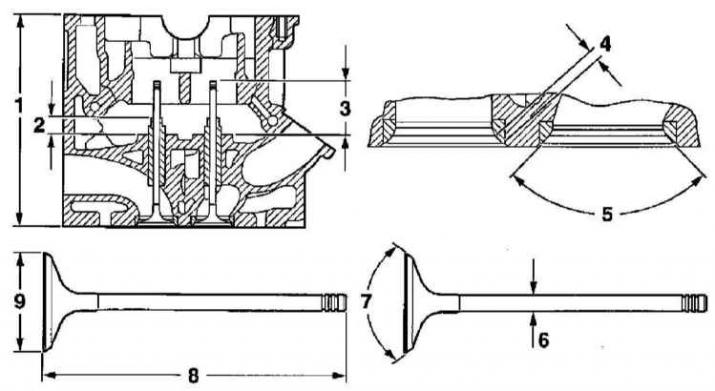

Dimensional characteristics of the installation of valves

1 — Height of a head of cylinders

2 - Installation height of the valve guide

3 — Installation height of the valve

4 - The width of the working chamfer of the valve seat in the cylinder head

5 - The angle of inclination of the chamfer of the valve seat

6 - Valve stem diameter

7 - The angle of inclination of the chamfer of the valve disc

8 - Valve length

9 — Diameter of a plate of the valve

Cylinder head

Maximum allowable flatness of the mating surface, mm

|

Gasoline engines |

0.05 |

|

Diesel engines |

|

|

Engines 1.7 l SOHC and DOHC |

0.1 |

|

Engines 2.0 l |

Data not provided |

Cylinder head height, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC

|

95.9—96.1 |

|

Engines 1.4, 1.6 L DOHC

|

134.9—135.1 |

|

Engine 1.8L DOHC

|

135.8—36.0 |

|

Engine 2.0L DOHC

|

134 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

106.10 |

|

105.75 |

|

Engines 1.7 L DOHC |

94.95—95.05 |

|

Engines 2.0 l |

140.0 |

Width of working chamfers of saddles of valves, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC | |

|

1.3—1.5 |

|

1.6—1.8 |

|

Engines 1.4, 1.6, 1.8 and 2.0 l DOHC | |

|

1.0—1.4 |

|

1.4—1.8 |

|

Diesel engines |

|

|

Engine 1.7 SOHC (inlet and outlet) | |

|

1.3 |

|

2.0 |

|

Engines 1.7 L DOHC (inlet and outlet) |

1.5—1.7 |

|

Engines 2.0 l (inlet and outlet) |

1.4—1.8 |

Valve seat angle

|

Diesel engines 1.7L DOHC |

90° |

Camshaft (s)

The value of axial play, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC

|

0.09—0.21 |

|

Engines 1.4, 1.6,1.8 and 2.0 l DOHC

|

0.04—0.015 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC

|

0.05—0.20 |

|

Engine 1.7L DOHC

|

Data not provided |

|

Engines 2.0 l

|

0.04—0.14 |

Maximum allowable value of radial runout, mm

|

Gasoline engines |

0.040 |

|

Diesel engines |

|

|

Engines 1.7 l SOHC and DOHC |

0.05 |

|

Engines 2.0 l |

0.06 |

Jaw lifting height, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC | |

|

5.61 |

|

6.12 |

|

Engines 1.4, 1.6,1.8 DOHC | |

|

8.5 |

|

8.0 |

|

2.0L DOHC | |

|

10.0 |

|

10.0 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

9.40 |

|

9.40 |

|

Engine 1.7L DOHC | |

|

7.68 |

|

7.77 |

|

Engines 2.0 l | |

|

8.0 |

|

8.0 |

The size of the gaps in the thrust bearings

Data not provided

Valves and guides

Protrusion height of the guide bushings above the surface of the head, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC |

80.85—81.25 |

|

Engines 1.4, 1.6 and 1.8 l DOHC |

10.70—11.00 |

|

Engine 2.0L DOHC |

13.7—14.0 |

|

Diesel engines |

|

|

Engines 2.0 l |

11.20—11.50 |

Valve stem diameter, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC | |

|

Standard size (identification mark K) | |

|

6.998—7.012 |

|

6.978—6.992 |

|

Repair size 0.075 mm (identification mark K1)

| |

|

7.073—7.087 |

|

7.053—7.067 |

|

Repair size 0.150 mm (identification mark K2)

| |

|

7.148—7.162 |

|

7.128—7.142 |

|

Engines 1.4 and 1.6 l DOHC | |

|

Standard size (GM identification label) | |

|

5.995—5.970 |

|

5.935—5.950 |

|

Repair size 0.075 mm (identification mark K1)

| |

|

6.030—6.045 |

|

6.010—6.025 |

|

Repair size 0.150 mm (identification mark K2)

| |

|

6.105—6.120 |

|

6.085—6.100 |

|

Engines 1.8 L DOHC | |

|

Standard size (GM identification label) | |

|

4.955—4.970 |

|

4.935—4.950 |

|

Engine 2.0L DOHC | |

|

Standard size (GM identification label) | |

|

5.955—5.970 |

|

5.945—5.960 |

|

Repair size 0.075 mm (identification mark K1)

| |

|

6.030—6.045 |

|

6.020—6.035 |

|

Repair size 0.150 mm (identification mark K2)

| |

|

6.105—6.120 |

|

6.095—6.110 |

|

Diesel engines |

|

|

Engines 1.7 L DOHC | |

|

Standard size | |

|

7.970—7.985 |

|

7.955—7.970 |

|

Repair size 0.075 mm | |

|

8.045—8.060 |

|

8.030—8.045 |

|

Repair size 0.150 mm | |

|

8.120—8.135 |

|

8.105—8.120 |

|

Engines 1.7 L DOHC | |

|

6.00 |

|

6.00 |

|

Engines 2.0 l | |

|

Standard size (identification mark K) | |

|

5.955—5.970 |

|

5.945—5.960 |

|

Repair size 0.075 mm (identification mark K1)

| |

|

6.030—6.045 |

|

6.020—6.035 |

|

Repair size 0.150 mm (identification mark K2)

| |

|

6.105—6.120 |

|

6.095—6.110 |

Maximum allowable valve runout, mm

|

All engines |

0.03 |

Inner diameter of guide bushings, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC | |

|

7.030—7.050 |

|

7.105—7.125 |

|

7.180—7.200 |

|

Engines 1.4 and 1.6 l DOHC | |

|

6.000—6.012 |

|

6.075—6.090 |

|

6.150—6.165 |

|

Engines 1.8 L DOHC | |

|

5.000—5.012 |

|

5.075—5.087 |

|

5.150—5.162 |

|

Engine 2.0L DOHC | |

|

6.000—6.012 |

|

6.075—6.090 |

|

6.150—6.165 |

|

Diesel engines |

|

|

Engines 1.7 L DOHC | |

|

8.000—8.017 |

|

8.075—8.092 |

|

8.150—8.167 |

|

Engines 1.7 L DOHC |

7.000—7.015 |

|

Engines 2.0 l | |

|

6.000—6.012 |

|

6.075—6.090 |

|

6.150—6.165 |

Size of a backlash of landing of a core of the valve in the directing plug, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC | |

|

0.018—0.052 |

|

0.038—0.072 |

|

Engines 1.4,1.6 and 1.8 l DOHC |

Data not provided |

|

Engine 2.0L DOHC | |

|

0.030—0.057 |

|

0.040—0.067 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

Rated value | |

|

0.015 |

|

0.030 |

|

Limit value | |

|

0.047 |

|

0.062 |

|

Engines 1.7 L DOHC | |

|

Rated value | |

|

0.019 |

|

0.0215 |

|

Limit value

|

Data not provided |

|

Engines 2.0 l |

Data not provided |

Valve length, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC | |

|

99.35 |

|

99.65 |

|

Engines 1.4 and 1.6 l DOHC | |

|

101.51—101.93 |

|

100.55—100.97 |

|

Engine 1.8L DOHC | |

|

100.1—100.3 |

|

99.4—99.6 |

|

Engine 2.0L DOHC | |

|

102.0—102.2 |

|

92.15—92.35 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

123.22—123.27 |

|

Engines 1.7 L DOHC | |

|

98.45 |

|

98.10 |

|

Engines 2.0 l | |

|

97.1—97.2 |

|

96.9—97.0 |

Height of installed valves, mm

|

1.6L SOHC petrol engine |

13.75—14.35 |

Diameter of valve plates, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC | |

|

38.0 |

|

31.0 |

|

Engines 1.4 and 1.6 l DOHC | |

|

31.0 |

|

27.5 |

|

Engine 1.8L DOHC | |

|

31.2 |

|

27.5 |

|

Engine 2.0L DOHC | |

|

31.9—32.1 |

|

28.9—29.1 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

36.0 |

|

32.0 |

|

Engines 1.7 L DOHC | |

|

27.15 |

|

28.5 |

|

Engines 2.0 l | |

|

28.9—29.1 |

|

25.9—26.1 |

The angle of inclination of the working chamfers of the valve plates

|

Diesel engines 1.7L DOHC |

89° |

Valve guide length, mm

|

Diesel engines 1.7L DOHC |

41.75—42.25 |

Valve clearance on a cold engine (1.7L DOHC diesel engine only), mm

|

intake valves |

0.4 ± 0.5 |

|

exhaust valves |

0.4 ± 0.5 |

Balance Assembly (2.0 DOHC petrol engine if equipped)

Engagement clearance, mm

|

0.02—0.6 |

The ratio of the plate code to its thickness

|

Code 55

|

0.535—0.565 |

|

Code 58

|

0.565—0.595 |

|

Code 61

|

0.595—0.625 |

|

Code 64

|

0.625—0.655 |

|

Code 67

|

0.655—0.685 |

|

Code 70

|

0.685—0.715 |

|

Code 73

|

0.715—0.745 |

|

Code 76

|

0.745—0.775 |

|

Code 79

|

0.775—0.805 |

|

Code 82

|

0.805—0.835 |

|

Code 85

|

0.835—0.865 |

Cylinder block

Maximum allowable flatness of the mating surface, mm

|

Gasoline engines |

0.05 |

|

Diesel engines |

|

|

Engines 1.7 l SOHC and DOHC |

0.1 |

|

Engines 2.0 l |

Data not provided |

Cylinder diameter, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC | |

|

Standard size | |

|

78.975—78.985 |

|

78.985—78.995 |

|

78.995—79.005 |

|

79.005—79.015 |

|

79.015—79.025 |

|

Repair size 0.5 mm (Group 7)

|

79.465—79.475 |

|

Engines 1.4 L DOHC | |

|

Standard size | |

|

77.575—77.585 |

|

77.585—77.595 |

|

77.595—77.605 |

|

77.605—77.615 |

|

77.615—77.625 |

|

Repair size 0.5 mm (Group 7)

|

78.065—78.075 |

|

Engines 1.6 L DOHC | |

|

Standard size | |

|

78.975—78.985 |

|

78.985—78.995 |

|

78.995—79.005 |

|

79.005—79.015 |

|

79.015—79.025 |

|

Repair size 0.5 mm (Group 7)

|

79.465—79.475 |

|

Engines 1.8 L DOHC | |

|

Standard size | |

|

80.485—80.495 |

|

80.495—80.505 |

|

80.505—80.515 |

|

80.515—80.525 |

|

Repair size 0.5 mm (Group 00)

|

80.995—81.005 |

|

Engine 2.0L DOHC | |

|

Standard size | |

|

85.975—78.985 |

|

85.985—85.995 |

|

85.995—86.005 |

|

86.005—86.015 |

|

86.015—86.025 |

|

Repair size 0.5 mm (Group 7)

|

86.465—86.475 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

Standard size | |

|

82.475—82.485 |

|

82.485—82.495 |

|

82.495—82.505 |

|

82.505—82.515 |

|

82.515—82.525 |

|

Repair size 0.5 mm (Group 7)

|

82.965—82.975 |

|

Engines 1.7 L DOHC | |

|

79.000—79.009 |

|

79.010—79.019 |

|

79.020—79.029 |

|

Engines 2.0 l | |

|

Standard size | |

|

83.975—83.985 |

|

83.985—83.995 |

|

83.995—84.005 |

|

84.005—84.015 |

|

84.015—84.025 |

|

Repair size 0.5 mm

|

84.465—84.475 |

The inner diameter of the beds of main bearings without liners (1.7L DOHC diesel engines only), mm

|

Group 1 |

55.992—56.000 |

|

Group 2 |

55.984—55.992 |

|

Group 3 |

55.976—55.984 |

Maximum admissible ovality of cylinders, mm

|

Gasoline engines |

0.013 |

Maximum allowable taper of cylinders, mm

|

Gasoline engines |

0.013 |

|

Diesel engines |

|

|

Engines 1.7 l SOHC and DOHC |

0.015 |

|

Engines 2.0 l |

Data not provided |

Connecting rod and piston assemblies

Pistons and piston rings

Piston diameter, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC | |

|

Standard size | |

|

78.955—78.965 |

|

78.965—78.975 |

|

78.975—78.985 |

|

78.985—78.995 |

|

78.995—79.005 |

|

Repair size 0.5 mm (Group 7)

|

79.445—79.455 |

|

Engines 1.4 L DOHC | |

|

Standard size | |

|

77.555—77.565 |

|

77.565—77.575 |

|

77.575—77.585 |

|

77.585—77.595 |

|

77.595—77.605 |

|

Repair size 0.5 mm (Group 7)

|

78.045—78.055 |

|

Engines 1.6 L DOHC | |

|

Standard size | |

|

78.955—78.965 |

|

78.965—78.975 |

|

78.975—78.985 |

|

78.985—78.995 |

|

78.995—79.005 |

|

Repair size 0.5 mm (Group 7)

|

79.445—79.455 |

|

Engines 1.8 L DOHC | |

|

Standard size | |

|

80.455—80.465 |

|

80.465—80.475 |

|

80.475—80.485 |

|

80.485—80.495 |

|

Repair size 0.5 mm (Group 00)

|

80.965—80.975 |

|

Engine 2.0L DOHC | |

|

Standard size | |

|

85.945—78.955 |

|

85.955—85.965 |

|

85.965—85.975 |

|

85.975—85.985 |

|

85.985—85.995 |

|

Repair size 0.5 mm (Group 7)

|

86.435—86.445 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

Standard size | |

|

82.445—82.455 |

|

82.455—82.465 |

|

82.465—82.475 |

|

82.475—82.485 |

|

82.485—82.495 |

|

Repair size 0.5 mm (Group 7)

|

82.935—82.945 |

|

Engines 1.7 L DOHC | |

|

78.930—78.939 |

|

78.940—78.949 |

|

78.950—78.959 |

|

Engines 2.0 l | |

|

Engine X20DTL/Y20DTL | |

| |

|

83.905—83.915 |

|

83.915—83.925 |

|

83.925—83.935 |

|

83.935—83.945 |

|

83.945—83.955 |

|

84.395—84.405 |

|

Engine X20DTH | |

| |

|

83.885—83.915 |

|

83.895—83.905 |

|

83.905—83.915 |

|

83.915—83.925 |

|

83.925—83.935 |

|

84.375—84.385 |

Piston fit clearance in cylinder, mm

|

Gasoline engines |

0.02—0.04 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

0.02—0.04 |

|

Engine 1.7L DOHC |

0.061—0.08 |

|

Engines 2.0 l |

|

|

0.06—0.08 |

|

0.08—0.10 |

Piston protrusion (diesel engines 1.7 l), mm

|

SOHC engine |

0.65—0.095 |

|

DOHC engine |

0.063—0.083 |

Clearances in piston ring locks, mm

|

Gasoline engines |

|

|

0.3—0.5 |

|

0.4—1.4 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

0.20—0.40 |

|

0.25—0.50 |

|

Engine 1.7L DOHC | |

|

0.25—0.35 |

|

0.20—0.30 |

|

0.20—0.40 |

|

Engines 2.0 l | |

|

0.25—0.50 |

|

0.25—0.50 |

Thickness of piston rings, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC | |

|

1.2 |

|

1.5 |

|

3.0 |

|

Engine 1.4L DOHC | |

|

1.2 |

|

1.5 |

|

3.0 |

|

Engines 1.6 and 2.0 l DOHC | |

|

1.5 |

|

1.5 |

|

3.0 |

|

Engine 1.8L DOHC | |

|

1.2 |

|

1.2 |

|

2.0 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

2.0 |

|

3.0 |

|

Engine 1.7L DOHC | |

|

2.0 |

|

1.5 |

|

3.0 |

|

Engines 2.0 l | |

| |

|

2.0 |

|

2.5 |

|

1.75 |

|

3.0 |

The value of the side clearance of the ring fit in the piston groove, mm

|

Gasoline engines |

|

|

Engine 1.6 l SOHC and 1.4, 1.6 and 1.8 l DOHC

| |

|

0.02—0.04 |

|

0.04—0.06 |

|

0.01—0.03 |

|

Engine 2.0 DOHC | |

|

0.02—0.04 |

|

0.01—0.03 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

0.12—0.18 |

|

0.12—0.15 |

|

0.025—0.15 |

|

Engine 1.7L DOHC | |

|

0.09—0.15 |

|

0.04—0.15 |

|

0.02—0.15 |

|

Engines 2.0 l | |

|

Engine X20DTL/Y20DTL | |

|

0.11—0.16 |

|

0.05—0.09 |

|

0.03—0.07 |

|

Y20DTH engine | |

|

0.08—0.12 |

|

0.05—0.09 |

|

0.03—0.07 |

Piston pins

Diameter, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC and 1.4, 1.6 and 1.8 l DOHC |

17.997—18.000 |

|

Engine 2.0L DOHC |

21.000 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

26 |

|

Engine 1.7L DOHC |

27 |

|

Engines 2.0 l |

29 |

Length, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC and 1.4, 1.6 and 1.8 l DOHC |

55 |

|

Engine 2.0L DOHC |

55.7—58.0 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

69 |

|

Engine 1.7L DOHC |

64 |

|

Engines 2.0 l |

68 |

Gap of landing of a finger in the piston, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC |

0.009—0.012 |

|

Engines 1.4, 1.6 and 1.8 l DOHC |

0.007—0.010 |

|

Engine 2.0L DOHC |

0.011—0.014 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

0.007—0.011 |

|

Engine 1.7L DOHC |

0.002—0.012 |

Gap of landing of a finger in the top head of a rod, mm

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

0.014—0.025 |

|

Engine 1.7L DOHC |

0.002—0.015 |

Connecting rods

The value of axial play on the neck of the crankshaft, mm

|

Gasoline engines |

|

|

Engine 1.6L SOHC |

0.07—0.24 |

|

Engines 1.4, 1.6 and 1.8 l DOHC |

0.11—0.24 |

|

Engine 2.0L DOHC |

0.07—0.24 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

0.20—0.40 |

|

Engine 1.7L DOHC |

0.25—0.58 |

|

Engines 2.0 l |

0.07—0.28 |

Maximum allowable weight difference between connecting rods (1.7L SOHC and DOHC diesel engines only), G

|

4 |

Crankshaft

The value of the axial play of the crankshaft, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC and 1.4, 1.6 and 1.8 l DOHC |

0.1—0.2 |

|

Engine 2.0L DOHC |

0.03—0.15 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

0.06—0.30 |

|

Engine 1.7L DOHC |

0.03—0.15 |

|

Engines 2.0 l |

0.05—0.15 |

Diameter of main journals, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC and 1.4, 1.6 and 1.8 l DOHC | |

|

Standard size

|

54.980—54.997 |

|

First repair size (0.25mm)

|

54.730—54.747 |

|

Second repair size (0.50 mm)

|

54.482—54.495 |

|

Engine 2.0L DOHC | |

|

Standard size | |

|

57.974—57.981 |

|

57.981—57.988 |

|

57.988—57.995 |

|

57.732—57.745 |

|

57.482—57.495 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

Standard size

|

57.974—57.995 |

|

First repair size (0.25mm)

|

57.732—57.738 |

|

Second repair size (0.50 mm)

|

57.482—57.495 |

|

Engine 1.7L DOHC | |

|

First size group (one cutout)

|

51.928—51.938 |

|

Second size group (two cutouts)

|

51.918—51.928 |

|

Engine 2.0 l | |

|

Standard size | |

|

67.966—67.974 |

|

67.974—67.982 |

|

67.716—67.732 |

|

67.466—67.482 |

Diameter of connecting rod journals, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC and 1.4, 1.6 and 1.8 l DOHC

| |

|

Standard size

|

42.971—42.987 |

|

First repair size (0.25mm)

|

42.721—42.737 |

|

Second repair size (0.50 mm)

|

42.471—42.487 |

|

Engine 2.0L DOHC | |

|

Standard size

|

48.970—48.988 |

|

First repair size (0.25mm)

|

48.720—48.738 |

|

Second repair size (0.50 mm)

|

48.470—48.488 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

Standard size

|

48.970—48.988 |

|

First repair size

|

48.720—48.738 |

|

Second repair size (0.50 mm)

|

48.470—48.488 |

|

Engine 1.7L DOHC |

Data not provided |

|

Engine 2.0 l | |

|

Standard size

|

48.971—48.990 |

|

First repair size (0.25mm)

|

48.721—48.740 |

|

Second repair size (0.50 mm)

|

48.471—48.490 |

Maximum allowable neck ovality, mm

|

Gasoline engines |

0.04 |

|

Diesel engines |

|

|

Engines 1.7 l SOHC and DOHC |

Data not provided |

|

Engines 2.0 l |

0.03 |

Maximum allowable value of the taper of the necks, mm

|

Gasoline engines |

Data not provided |

|

Diesel engines |

Data not provided |

Maximum permissible value of the radial runout of the shaft, mm

|

Gasoline engines |

0.03 |

|

Diesel engines |

|

|

Engines 1.7 l SOHC |

0.06 |

|

Engines 1.7 L DOHC |

0.04—0.082 |

|

Engines 2.0 l |

0.03 |

The size of the gaps in the main bearings, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC and 1.4, 1.6 and 1.8 l DOHC |

0.017—0.047 |

|

Engine 2.0L DOHC |

0.015—0.040 |

|

Diesel engines |

|

|

Engines 1.7 l SOHC |

0.030—0.080 |

|

Engines 1.7 L DOHC |

0.030—0.058 |

|

Engines 2.0 l |

0.016—0.069 |

The size of the gaps in the connecting rod bearings, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC and 1.4, 1.6 and 1.8 l DOHC |

0.019—0.071 |

|

Engine 2.0L DOHC |

0.006—0.031 |

|

Diesel engines |

|

|

Engines 1.7 l SOHC |

0.025—0.100 |

|

Engines 1.7 L DOHC |

0.025—0.058 |

|

Engines 2.0 l |

0.022—0.061 |

Lubrication system

Oil pump type

|

Gasoline engines |

|

|

Engines 1.6 l SOHC |

Gear, directly driven by crankshaft shaft |

|

Engines 1.4, 1.6, 1.8 and 2.0 l DOHC |

Rotary, driven by timing belt |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

Rotary, with direct drive from the crankshaft |

|

Engine 1.7L DOHC |

Rotary, driven by timing belt |

|

Engines 2.0 l |

Gear, directly driven by crankshaft shaft |

The minimum allowable pressure at idle at an engine temperature of at least 80°C, bar

|

Gasoline engines |

1.5 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC |

3.9 |

|

Engine 1.7L DOHC |

1.27 |

|

Engines 2.0 l |

1.5 |

The value of the working clearances in the oil pump, mm

|

Gasoline engines |

|

|

Engines 1.6 l SOHC | |

|

Gear teeth clearance

|

0.08—0.15 |

|

Axial play of gears

|

0.10—0.20 |

|

Engines 1.4, 1.6, 1.8 and 2.0 l DOHC | |

|

Gap between gear teeth

|

0.10—0.20 |

|

Axial play of gears

|

0.03—0.10 |

|

Diesel engines |

|

|

Engine 1.7 l SOHC | |

|

Lateral fit clearance of the outer rotor | |

|

0.24—0.36 |

|

0.40 |

|

The gap between the teeth of the rotors | |

|

0.10 |

|

0.145 |

|

Axial play of the rotors | |

|

0.035—0.100 |

|

0.150 |

|

Engine 1.7L DOHC | |

|

Lateral fit clearance of the outer rotor | |

|

0.24—0.36 |

|

0.40 |

|

The gap between the teeth of the rotors | |

|

0.13—0.15 |

|

0.20 |

|

Axial play of the rotors | |

|

0.035—0.100 |

|

0.150 |

|

Engines 2.0 l |

Data not provided |

Tightening force of threaded connections, Nm

|

Connection type |

Meaning |

|

Wheel bolts |

110 |

Gasoline engines

Engine 1.6L SOHC

|

Connection type |

Meaning |

|

Timing cover bolts | |

|

4 |

|

6 |

|

Timing Belt Tensioner Fixing Bolt

|

20 |

|

Bolts of fastening of a cover of the gas-distributing mechanism

|

8 |

|

Camshaft gear bolt

|

45 |

|

Camshaft rear thrust plate bolts

|

8 |

|

Bolts of an end cover of the case of the gas-distributing mechanism

|

8 |

|

Connecting rod cap bolts * | |

|

25 |

|

pull at an angle of 30° |

|

Water pump mounting bolts

|

8 |

|

Crankshaft Pulley Bolt * | |

|

95 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Bolts of fastening of a rotor of the gauge of position of a cranked shaft (CKP)

|

8 |

|

Bolts of fastening of a head of cylinders * | |

|

25 |

|

pull at an angle of 60° |

|

pull at an angle of 60° |

|

pull at an angle of 60° |

|

Bolts of fastening of a driving disk * | |

|

55 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Fastener of a cover of a driving disk

|

8 |

|

Power unit suspension mounts | |

|

Left support | |

|

55 |

|

55 |

|

20 |

|

35 |

|

15 |

|

front support | |

|

55 |

|

Rear support | |

|

55 |

|

55 |

|

60 |

|

Right support | |

|

55 |

|

35 |

|

Bolts of fastening of the engine to transmission | |

|

60 |

|

Flywheel mounting bolts * | |

|

35 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Bolts of fastening of a forward subframe * | |

|

90 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Bolts of fastening of covers of radical bearings crankshaft shaft | |

|

50 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Emergency oil pressure sensor

|

30 |

|

Oil pump | |

|

8 |

|

6 |

|

50 |

|

Oil intake bolts

|

8 |

|

Bolts of fastening of the pallet crankcase of the engine | |

|

Models without A/C (stamped pallet) | |

|

10 |

|

55 |

|

Models with A/C (cast pallet) | |

|

10 |

|

40 |

|

45 |

* Use new bolts.

Engines 1.4, 1.6 and 1.8 l DOHC

|

Connection type |

Meaning |

|

Timing cover bolts | |

|

3 |

|

6 |

|

Bolt of fastening of an intermediate roller of the timing drive

|

25 |

|

Timing Belt Tensioner Bolt

|

20 |

|

Auxiliary drive belt tensioner mounting bolt

units to the generator bracket

|

35 |

|

Pan slinger bolts

|

8 |

|

Camshaft bearing cap bolts

|

8 |

|

Bolts of a cover of the case of the gas-distributing mechanism

|

8 |

|

Distribution position sensor mounting bolts

shaft (CMP)

|

8 |

|

Bolt of fastening of a cogwheel of a camshaft * | |

|

50 |

|

pull at an angle of 60° |

|

pull at an angle of 15° |

|

Bolt of fastening of covers of the lower heads of connecting rods * | |

|

25 |

|

tighten by 30° |

|

Crankshaft Pulley Bolt * | |

|

95 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Bolt of fastening of an arm of fastening of the sensor of position

crankshaft (CKP)

|

8 |

|

Bolts of fastening of a head of cylinders * | |

|

25 |

|

pull through 90° |

|

pull through 90° |

|

pull through 90° |

|

pull at an angle of 45° |

|

Bolts of fastening of a drive disk

|

60 |

|

Power unit suspension mounts | |

|

Left support | |

|

20 |

|

35 |

|

55 |

|

front support | |

|

60 |

|

55 |

|

Rear support | |

|

55 |

|

55 |

|

55 |

|

Right support | |

|

50 |

|

45 |

|

55 |

|

55 |

|

Bolts of fastening of the engine to transmission | |

|

60 |

|

Bolts of fastening of a forward subframe * | |

|

90 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Flywheel mounting bolts * | |

|

35 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Bolts of fastening of covers of radical bearings * | |

|

50 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Bolts of fastening of the gauge of level of motive oil with

TORX head

|

8 |

|

Oil pump | |

|

8 |

|

6 |

|

50 |

|

30 |

|

Oil intake bolts

|

8 |

|

Bolts of fastening of the pallet crankcase of the engine | |

|

10 |

|

40 |

|

|

|

10 |

|

45 |

* Use new bolts.

Engine 2.0L DOHC

|

Connection type |

Meaning |

|

Timing belt cover bolts

|

6 |

|

Bolt of fastening of an intermediate roller of the timing drive | |

|

25 |

|

25 |

|

Timing Belt Tensioner Bolt

|

20 |

|

Auxiliary drive belt tensioner mounting bolt units to the generator bracket | |

|

35 |

|

25 |

|

Bolts of fastening of balancing assembly to the block of cylinders

| |

|

20 |

|

pull at an angle of 45° |

|

Bolts of fastening of an oil deflector plate of the pallet

|

8 |

|

Bolts of fastening of covers of bearings of camshafts

|

8 |

|

Bolts of fastening of a cover of the gas-distributing mechanism

|

8 |

|

Bolts of fastening of the gauge of position of a camshaft (CMP)

|

6 |

|

Bolt of fastening of a cogwheel of a camshaft *

| |

|

50 |

|

pull at an angle of 60° |

|

pull at an angle of 15° |

|

Bolts of fastening of covers of the lower heads of connecting rods * | |

|

35 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Crankshaft Pulley Central Bolt * | |

|

95 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Bolts of fastening of a pulley of a cranked shaft

|

20 |

|

Bolt of fastening of a cogwheel of a cranked shaft | |

|

130 |

|

pull at an angle of 50° |

|

Bolts of fastening of a head of cylinders * | |

|

25 |

|

pull through 90° |

|

pull through 90° |

|

pull through 90° |

|

pull at an angle of 15° |

|

Bolts of fastening of a driving disk * | |

|

55 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Power unit suspension mounts | |

|

Left support | |

|

20 |

|

35 |

|

55 |

|

front support | |

|

60 |

|

55 |

|

Rear support | |

|

55 |

|

55 |

|

55 |

|

Right support | |

|

50 |

|

45 |

|

55 |

|

55 |

|

Bolts of fastening of the engine to transmission | |

|

60 |

|

Flywheel mounting bolts * | |

|

65 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Bolts of fastening of the bridge of covers of radical bearings to the block cylinders | |

|

20 |

|

pull at an angle of 45° |

|

Bolts of fastening of covers of radical bearings * | |

|

50 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Bolts of the bridge of covers to covers of radical bearings

|

20 |

|

Oil level sensor mounting bolts (with TORX head)

|

8 |

|

Oil pump | |

|

8 |

|

6 |

|

50 |

|

Oil intake bolts | |

|

8 |

|

20 |

|

Bolts of fastening of the pallet crankcase of the engine | |

|

Bolts of fastening of the bottom section of the pallet | |

|

8 |

|

Bolts of fastening of the main (cast) pallet sections | |

|

20 |

|

40 |

|

drain plug

|

10 |

* Use new bolts/nuts.

Diesel engines

Engines 1.7 l SOHC

|

Connection type |

Meaning |

|

Bolts of fastening of a basic arm of the compressor To/in

|

40 |

|

Fasteners of the compressor K/V

|

20 |

|

Fixture of the top basic arm of the generator

|

18 |

|

Lower alternator mounting bolt

|

25 |

|

Compressor bracket to drive belt tensioner auxiliary units | |

|

8 |

|

Bolt of fastening of a cogwheel of a camshaft * | |

|

75 |

|

tighten by 60° |

|

Fastening of a hose of a cooling path to the block of cylinders

|

20 |

|

Water pump | |

|

25 |

|

10 |

|

Bolts of fastening of covers of the lower heads of connecting rods * | |

|

35 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Bolts of fastening of a pulley of a cranked shaft

|

20 |

|

Bolt of fastening of the gauge of frequency of rotation of a cranked shaft

|

8 |

|

Bolt of fastening of a cogwheel of a cranked shaft * | |

|

130 |

|

pull at an angle of 45° |

|

Bolts of fastening of a head of cylinders | |

|

25 |

|

pull through 90° |

|

pull through 90° |

|

pull at an angle of 45° |

|

after warming up the engine in 2 stages, hold on to angles of 30°15° |

|

Power unit suspension mounts | |

|

Left support | |

|

55 |

|

55 |

|

20 |

|

35 |

|

15 |

|

front support | |

|

60 |

|

55 |

|

Rear support | |

|

55 |

|

55 |

|

80 |

|

Right support | |

|

55 |

|

55 |

|

35 |

|

50 |

|

Bolts of fastening of the engine to transmission

|

60 |

|

Bolts of fastening of transport eyes of the power unit

|

25 |

|

Bolts of fastening of a reception pipe of system of release of the fulfilled gases

|

20 |

|

EGR valve to exhaust manifold bolts

|

8 |

|

Nuts of fastening of an exhaust manifold to a head of the block *

|

22 |

|

Bolts of fastening of a final collector to a head of the block

|

22 |

|

Fastener of a basic arm of a final collector

|

25 |

|

Flywheel mounting bolts * | |

|

65 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Bolts of fastening of a cogwheel of TNVD

|

15 |

|

Bolts of nipple connectors for injection pump

|

25 |

|

Bolts of fastening of the bridge of covers of radical bearings | |

|

20 |

|

pull at an angle of 45° |

|

Bolts of fastening of covers of radical bearings * | |

|

50 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Oil cooler support bracket bolts

|

5 |

|

Oil cooler pipe union

|

30 |

|

Probe guide tube support bracket bolt

engine oil level to block

|

25 |

|

Oil filter

|

15 |

|

Bolts of fastening of the reducing valve of pressure of oil

|

50 |

|

Oil pressure sensor

|

40 |

|

Bolts of fastening of the oil pump to the block of cylinders

|

8 |

|

Bolts of fastening of a cover of the oil pump

|

10 |

|

Oil intake bolts * | |

|

8 |

|

pull at an angle of 30° |

|

Mounting the oil temperature sensor in the main section of the sump

|

18 |

|

Bolts of fastening of the pallet crankcase of the engine | |

|

20 |

|

40 |

| |

|

8 |

|

pull at an angle of 30° |

|

10 |

|

Wheel bolts

|

110 |

|

thermostat housing

|

15 |

|

Timing cover bolts

|

8 |

|

Bolt of fastening of an intermediate roller of a timing belt

|

40 |

|

Bolt of fastening of a tension roller of a timing belt

|

25 |

|

Fastening of an oil pipe of a turbocharger on the block of cylinders

|

20 |

|

Oil pipe attachment to turbocharger

|

30 |

|

Fixing the oil return pipe to the sump

|

45 |

|

Fastening the vacuum pump to the gas distribution mechanism housing

|

28 |

* Use new mounting bolts/nuts.

Engines 1.7 L DOHC

|

Connection type |

Meaning |

|

Bolts of fastening of the generator to a basic arm | |

|

19 |

|

48 |

|

Attaching the accessory drive belt tensioner to the bracket

generator

|

50 |

|

Attachment of the guide roller of the drive belt of auxiliary units

to the generator bracket

|

38 |

|

Bolts of fastening of an oil deflector plate of the pallet to the block of cylinders

|

19 |

|

Nuts of fastening of covers of basic bearings of a camshaft

| |

|

21 |

|

43 |

|

Bolts of fastening of a cover of the gas-distributing mechanism

|

10 |

|

Mounting the gas distribution mechanism housing

|

22 |

|

Fastening of a persistent plate of a camshaft

|

8 |

|

Water pump mounting bolts | |

|

24 |

|

10 |

|

Fastening of a hose of a cooling path to the block of cylinders

|

95 |

|

coolant temperature sensor (ECT)

|

22 |

|

Nuts of fastening of covers of the lower heads of connecting rods * | |

|

25 |

|

pull at an angle of 100° |

|

pull at an angle of 15° |

|

Fastening of the gauge of frequency of rotation of a cranked shaft

|

10 |

|

crankshaft pulley bolts

|

20 |

|

Crankshaft oil seal housing bolts

|

10 |

|

Crankshaft gear bolt

|

196 |

|

Bolts of fastening of a head of cylinders * | |

|

40 |

|

pull at an angle of 60° |

|

pull at an angle of 15° |

|

pull at an angle of 60° |

|

pull at an angle of 15° |

|

Power unit suspension mounts | |

|

Left support | |

|

20 |

|

35 |

|

55 |

|

front support | |

|

60 |

|

55 |

|

Rear support | |

|

55 |

|

55 |

|

60 |

|

Right support | |

|

50 |

|

45 |

|

55 |

|

Bolts of fastening of the engine to transmission | |

|

40 |

|

60 |

|

Fastening the engine control unit bracket to the gas distribution housing

mechanism

|

10 |

|

Mounting the engine control unit to the bracket

|

6 |

|

Mounting eyes for transporting the engine

|

25 |

|

Fastening the EGR tube bracket to the timing gear housing

|

8 |

|

Attaching the EGR valve to the manifold

|

25 |

|

Flywheel mounting bolts * | |

|

30 |

|

pull at an angle of 45°—60° |

|

Fastening the fuel return line to the gas distribution housing

mechanism

|

15 |

|

glow plugs

|

20 |

|

Mounting the heat exchanger to the oil filter housing

|

12 |

|

Fastening of the injection pump control unit

|

10 |

|

Fastening the bracket of the injection pump control unit to the cylinder block

|

48 |

|

Fastening the injection pump to the bracket

|

19 |

|

Fastening of the injection pump bracket to the cylinder block

|

54 |

|

Fastening injection pump to the cylinder block

|

20 |

|

Nut of fastening of a cogwheel of TNVD

|

69 |

|

Fastening the oil sprayer bracket to the gas distribution housing

mechanism

|

22 |

|

Fuel line connectors

|

23 |

|

Bolts of fastening of covers of radical bearings

|

88 |

|

Bolts for fastening the guide tube of the dipstick for measuring the oil level

|

10 |

|

Oil feed tube to turbocharger

|

10 |

|

Oil filter cover fixing

|

25 |

|

Fastening of the oil filter to the block of cylinders

|

25 |

|

Adjustment Reducing Valve Bolt

|

30 |

|

Emergency oil pressure sensor

|

20 |

|

Bolts of fastening of a cover of the oil pump

|

10 |

|

Mounting the drive gear of the oil pump to the pump

|

44 |

|

Oil intake bolts

|

19 |

|

Bolts of fastening of the pallet crankcase of the engine | |

|

10 |

|

10 |

|

78 |

|

Fastening the thermostat housing to the cylinder head

|

24 |

|

Attaching the thermostat housing cover

|

24 |

|

Timing belt cover bolts

|

10 |

|

Idler pulley bolt

|

76 |

|

Fastening the timing belt tensioner pulley to the cylinder block

|

38 |

|

Timing belt tensioner spring retainer to rear cover

|

10 |

|

Fastening the turbocharger to the support bracket

|

26 |

|

Attaching the turbocharger to the manifold

|

26 |

|

Turbocharger oil feed tube fastening to the cylinder block

|

10 |

|

Fastening of a route trench of an electrical wiring to a head of cylinders

|

6 |

* Use new bolts/nuts.

Engines 2.0 l

|

Connection type |

Meaning |

|

Auxiliary drive belt tensioner bolts aggregates | |

|

42 |

|

23 |

|

Bolts of fastening of covers of basic gas-distributing mechanism

|

8 |

|

Bolt of fastening of an asterisk of a camshaft * | |

|

90 |

|

pull at an angle of 60° |

|

pull at an angle of 30° |

|

Bolt of fastening of covers of the lower heads of connecting rods * | |

|

35 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Bolt of fastening of a pulley of a cranked shaft | |

|

150 |

|

pull at an angle of 45° |

|

pull at an angle of 15° |

|

Bolts of fastening of a head of cylinders * | |

|

25 |

|

pull at an angle of 65° |

|

pull at an angle of 65° |

|

pull at an angle of 65° |

|

pull at an angle of 65° |

|

pull at an angle of 15° |

|

Timing chain cover bolts | |

|

X20DTL/Y20DTL |

20 |

|

Y20DTH * | |

|

20 |

|

pull at an angle of 30° |

|

pull at an angle of 5° |

|

Power unit suspension mounts | |

|

Left support | |

|

20 |

|

35 |

|

55 |

|

front support | |

|

60 |

|

55 |

|

Rear support | |

|

55 |

|

55 |

|

60 |

|

Right support | |

|

45 |

|

55 |

|

Bolts of fastening of the engine to transmission | |

|

40 |

|

60 |

|

Flywheel mounting bolts * | |

|

45 |

|

pull at an angle of 30° |

|

pull at an angle of 15° |

|

Injection pump sprocket mounting bolts | |

|

20 |

|

28 |

|

Bolts of fastening of a cover of an asterisk of TNVD

|

6 |

|

Main bearing cap bolts * | |

|

90 |

|

pull at an angle of 60° |

|

pull at an angle of 15° |

|

Bolts of fastening of the bridge of covers of radical bearings of a cranked shaft

|

20 |

|

Bolts of fastening of an oil cooler to the case of the oil filter

|

15 |

|

Oil pump | |

|

60 |

|

8 |

|

Oil intake bolts

|

8 |

|

Reducing valve plug

|

45 |

|

Bolts of fastening of oil atomizers in the block

|

22 |

|

Bolts of fastening of the pallet crankcase of the engine | |

|

20 |

| |

|

20 |

|

40 |

|

18 |

|

Timing chain cover bolts

|

20 |

|

Timing chain guide bolts

|

8 |

|

Bolt of an axis of a shoe of a tensioner of a timing chain

|

20 |

|

Fastening the timing chain tensioner cover

|

60 |

* Use new bolts/nuts.

Visitor comments