Note. Brake fluid is very hygroscopic - it absorbs moisture from the air, which, in addition to causing corrosion of parts of the brake system, lowers the boiling point of the fluid itself, and this can lead to brake failure during frequent heavy braking. Therefore, we recommend changing the brake fluid at least once every 2 years.

Check the tightness by external inspection:

- top from under the hood;

- from below the car (on a lift or a viewing ditch);

- from the sides of the vehicle with the wheels removed.

Note. Inspection of the part of the hydraulic drive working under pressure, conduct with an assistant.

He must press the brake pedal four or five times (in order to create pressure in the hydraulic drive) and keep it pressed until you inspect the hydraulic drive.

Inspection of a non-pressurized hydraulic actuator is acceptable, but less effective.

Notes:

- If a leak is found in the connections, tighten the clamps, plugs, nuts.

- Replace hoses and pipelines with mechanical damage.

- If the slave cylinders are leaking, repair or replace them.

You will need: special wrench for pipe fastening nuts or wrench «at 14», flat blade screwdriver, pliers.

Note. This is what special wrenches for pipe fastening nuts look like.

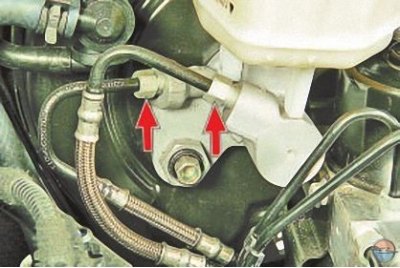

1. Inspect the brake master cylinder, pipe connections to the master cylinder…

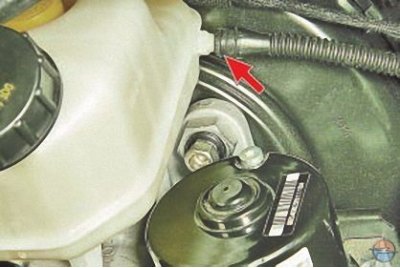

2.... and the reliability of connecting the hose to the master cylinder of the clutch release actuator mounted on the reservoir fitting (if the car is equipped with a manual transmission). If the car is equipped with an automatic transmission, the fitting hole is closed with a special spring-loaded plug.

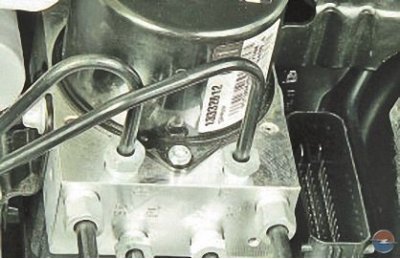

3. Inspect the connections of the pipelines with the hydro-electronic block of the anti-lock brake system (ABS).

Note. The battery holder has been removed for clarity.

4. Check for fluid leakage from the connections of the brake pipes with the hoses of the front..

5.... and rear brakes.

6. Carefully inspect the brake hoses. They should not have cracks, tears or abrasions. Press the brake pedal all the way: if swelling appears on the hose, it means that the threads of the hose braid are torn and it must be replaced.

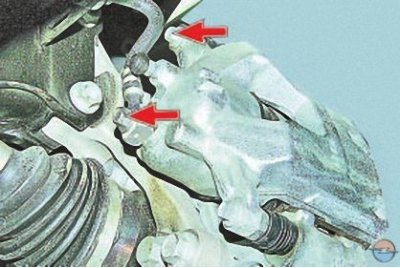

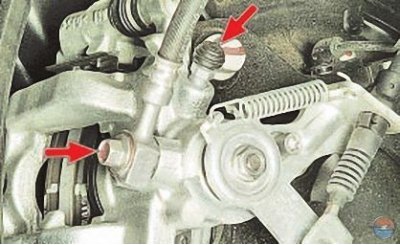

7. Inspect the hose connections to the working cylinders and the front brake air release valves..

8.... and rear wheels.

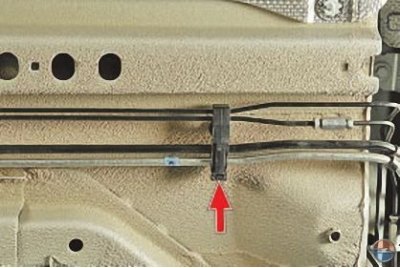

9. Check the condition of the plastic pipe holders. Replace damaged holders, as their looseness or breakage leads to vibration and, as a result, to breakage of pipelines.

Visitor comments