1. Summer tires - designed for operation in the summer, mainly on highways. The tread pattern consists of blocks or ribs separated by grooves (usually narrow).

2. All season tires types M+S (Mud + Snow - mud and snow) and R+W (Road + Winter - road and winter) - designed for operation both in winter and in summer. Provide an acceptable implementation of the performance characteristics for year-round use on highways and dirt roads. The pattern is more sparse than summer tires and may have microgrooves (lamellas), providing grip on icy and snowy roads.

3. Winter tires - serve for operation on winter roads and are:

- non-studded - made of soft grades of rubber, most often with a directional pattern with a large number of sipes and are intended mainly for use on cleared roads;

- studded or with the possibility of studding - made of rubber of medium hardness, with studs or marked places for mounting studs. The tread pattern is sparse, with a developed network of sipes. They provide good flotation in deep snow and well remove snow sludge. Studded tires have better grip on ice and packed snow compared to non-studded winter tires. However, studs impair traction on hard pavement and create increased noise.

Attention! Do not forget that in accordance with the requirements of the traffic rules, when using studded tires on a car, it is necessary to place a triangular warning sign with the letter «W». This will help the drivers behind you to choose the right distance, taking into account the higher braking capacity of your car on slippery surfaces.

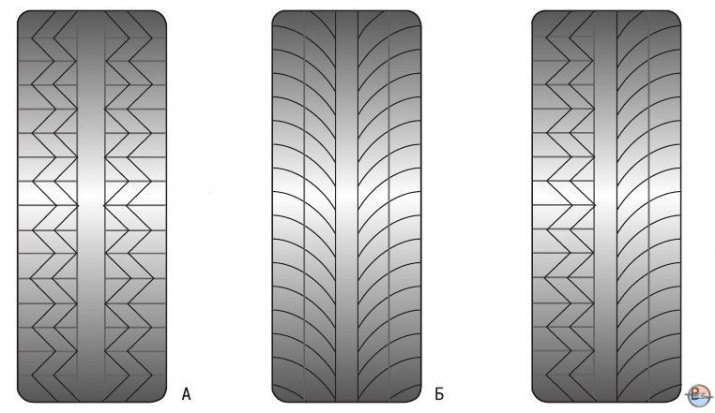

Pic. 1. Kinds of tread patterns:

A - non-directional; B - directed; B - symmetrical

Depending on the location of the elements tread pattern splints can be non-directional, directional or asymmetrical:

- non-directional pattern (see fig. 1, A) - symmetrical about the radial plane of the wheel (passing through its axis of rotation). It is the most versatile, so most tires are produced with this particular pattern;

- directional pattern (see Fig. 1, B) - symmetrical about the central plane of rotation of the wheel (passing through the middle of the tread). It has an improved ability to drain water from the contact patch with the road and reduced noise. The spare wheel coincides in the direction of rotation only with the wheels of one side of the car, but its temporary installation on the other side is permissible under the condition of driving at low speeds.

- asymmetrical pattern (see figure 1, B) - asymmetrical about the central plane of rotation of the wheel. It is used to implement different properties in one bus. For example, the outer side of a tire performs better on dry roads, while the inner side performs better on wet roads.

Tires are also distinguished by the way cavity sealing. Tires come with or without a tube.

Tubeless tires are generally considered to be more reliable than tubed tires because when the tire is punctured, air only exits the tire through the puncture hole, while tubeless tires allow air to escape from the tire cavity around the entire circumference of the mounting hole, since this connection is compromised.. Therefore, a tubeless tire leaves more time to maneuver before the moment when riding on a damaged wheel becomes dangerous. In addition, tubeless tires are lighter than their tubeless counterparts. On board a tubeless tire, you can find the designation «TUBELESS», «TL», on board the chamber «TUBETYPE», «TUBED TIRE».

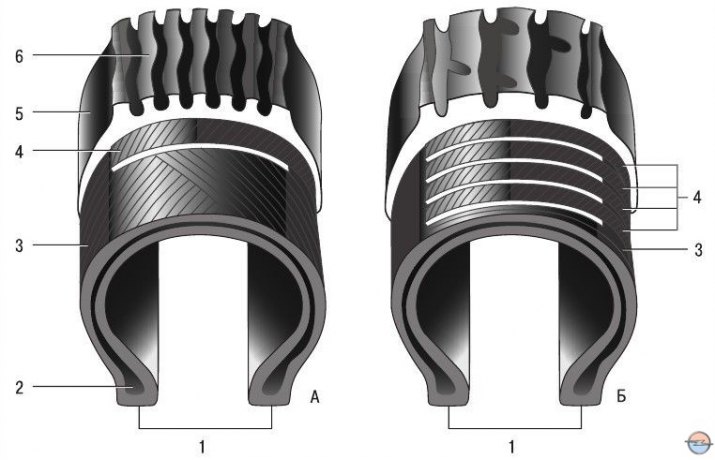

Pic. 2. Types of tire carcass: And - the tire of a diagonal design; B - tire of radial design; 1 - landing surfaces; 2 - rim; 3 - cord threads; 4 - breaker; 5 - sidewall; 6 - protector

According to the location of the threads in the carcass and breaker, the tires are diagonal and radial:

- diagonal tires A (pic. 2), the carcass of which consists of one or more pairs of cord layers arranged so that the threads of adjacent layers intersect. You probably won't have to choose tires based on this feature, as bias tires have almost completely been pushed out of the market by radial tires. The design of bias tires is outdated, but they continue to be produced in small numbers because they are relatively cheap to manufacture. The only benefit of these tires is that they have a stronger sidewall;

- radial tires B, in which the frame cord is stretched from one side to another without overlapping threads. The direction of thread tension follows from the name.

The thin soft shell of the frame along the outer surface is covered with a powerful flexible breaker - a belt made of high-strength inextensible cord, usually steel. Therefore, to the inscription «RADIAL» (radial) often added to tire sidewalls «BELTED» (belted) or «STEEL BELTED» (belted with steel).

This arrangement of the cord layers reduces the tension in the threads, which makes it possible to reduce the number of layers, gives the carcass elasticity, reduces heat generation and rolling resistance.

Radial tires have many advantages, they are more comfortable, durable, stable, and have lower rolling resistance. Bias tires are preferred for off-road and high impact wheel loads.

Visitor comments