The system is filled with ethylene glycol based liquid (antifreeze), which does not freeze at ambient temperatures down to -40°С.

Note. The procedure for replacing the coolant is described in subsection Coolant replacement.

Attention! It is not recommended to fill the cooling system with water, as antifreeze contains anti-corrosion and anti-foaming additives, as well as additives that prevent scale build-up.

Coolant is toxic! Avoid inhalation of vapors and contact with skin. Timely eliminate the violation of the tightness of the cooling system in order to avoid the ingress of coolant vapor into the vehicle interior during its operation. Your health is more valuable than a new cooling system pipe or a tube of sealant!

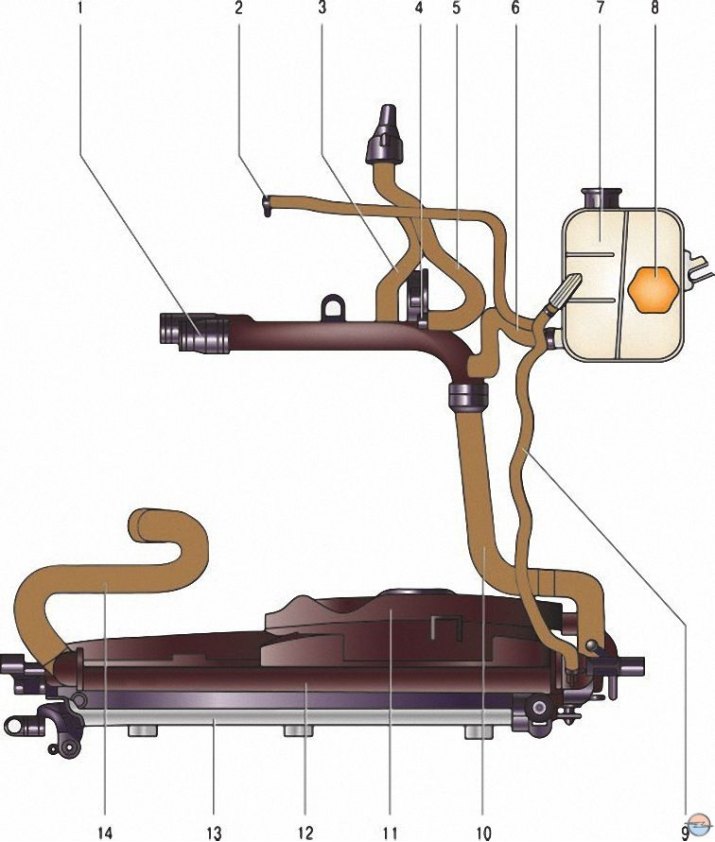

The engine cooling system is shown in fig. 1 on the example of the A16 XER engine.

Pic. 1. Elements of the cooling system: 1 - water distribution pipe; 2 - outlet hose for heating the throttle assembly; 3, 5 - hoses to the heater radiator; 4 - thermostat; 6 – a liquid hose of a broad tank; 7 - expansion tank; 8 – a stopper of a broad tank; 9 - steam outlet hose of the expansion tank; 10 - outlet hose of the radiator; 11 - electric fan; 12 - radiator of the cooling system; 13 - condenser of the air conditioning system; 14 - radiator inlet hose

The cooling systems of the other engines are arranged almost similarly, the difference lies in the arrangement of the system elements. In addition to the elements shown in the figure, the system includes a cast engine cooling jacket surrounding the cylinder walls in the block, combustion chambers and gas channels in the block head, as well as a passenger compartment heater radiator.

The normal thermal regime of the engine is determined by the temperature of the coolant, which is maintained automatically by a thermostat in the range of 90–100°C.

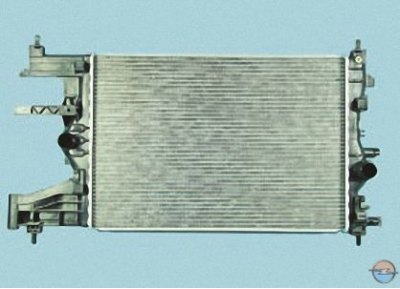

Radiator 12 (see fig. 1) with vertical liquid flow, with tubular-ribbed aluminum core and plastic tanks. At the bottom of the right tank is a drain cock. In the tanks there are inlet and outlet pipes of hoses to the water jacket of the engine, as well as a pipe of the hose connecting the radiator with the expansion tank.

Expansion tank 7 serves to compensate for the changing volume of the coolant depending on its temperature. The tank is made of translucent plastic. Marked on its walls «KALT/COLD» to control the level of the coolant, there is a filler neck on top, hermetically sealed with a plastic stopper 8 with two valves inside (inlet and outlet), collected in a single block. The exhaust valve opens at a pressure of 140–150 kPa (1.4–1.5 kgf/cm2), providing an increase in the temperature of the start of boiling of the coolant and preventing intense vaporization. When the liquid is cooled, its volume decreases and a vacuum is created in the system. The inlet valve in the plug opens at a vacuum of about 3 kPa (0.03 kgf/cm2) and lets air into the expansion tank.

Note. The serviceability of plug valves is very important for the normal operation of the cooling system, but often when problems arise (boiling of coolant, etc.) motorists pay attention only to the operation of the thermostat, forgetting to check the valves. Leakage of the exhaust valve leads to a decrease in the boiling point of the coolant, and its jamming in the closed state leads to an emergency increase in pressure in the system, which can cause damage to the radiator and hoses.

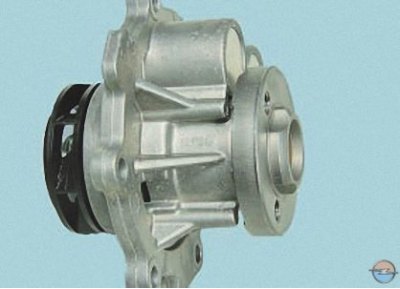

Water pump centrifugal type provides forced circulation of liquid in the cooling system, is installed on the front surface of the cylinder block and is driven by a V-ribbed belt for the auxiliary drive. The pump has sealed bearings that do not require relubrication. The pump is not subject to repair, in case of failure (fluid leakage or bearing damage) it is replaced as an assembly.

Thermostat 4 with a solid heat-sensitive filler maintains the normal operating temperature of the coolant and reduces the warm-up time of the engine. It is mounted in an aluminum housing on the thermostat module. At a coolant temperature of up to 80°C, the thermostat is completely closed and the liquid circulates through a small circuit, bypassing the radiator, which accelerates engine warm-up. At a temperature of 80°C, the thermostat begins to open, and at 95°C it comes off completely, providing fluid circulation through the radiator.

thermostat module, in the plastic case of which the coolant temperature sensor is located and can be installed (depending on configuration) valve for regulating the supply of fluid to the heater radiator, installed on the rear end of the cylinder head (for clarity shown on the removed cylinder head). A water distribution pipe 1 and hoses 3, 5 of the heater radiator are connected to the module.

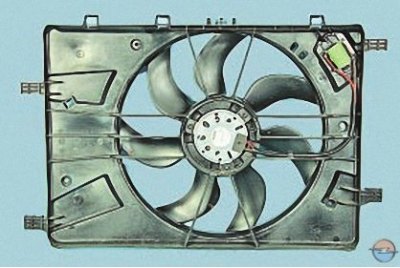

electric fan 11 with a plastic seven-bladed asymmetric impeller ensures the radiator is blown with air at low vehicle speeds, mainly in urban areas or on mountain roads, when the oncoming air flow is insufficient to cool the radiator.

To increase the efficiency of work, the fan is installed in the casing and attached to it at three points through rubber cushions. The casing, in turn, is attached to the radiator 12 V at four points.

The electric fan is controlled by the engine control unit, which receives information about the coolant temperature from the coolant temperature sensor located in the thermostat housing.

Into the cooling system with hoses 3 and 5 included interior heater radiator.

Visitor comments