- fuel supply, including fuel tank, fuel module, fuel filter and fuel pressure regulator (included in the fuel module), fuel lines and fuel rail with injectors;

- air supply, consisting of an air filter, an air supply sleeve and a throttle assembly;

- evaporative recovery, which includes an adsorber, an adsorber purge valve and connecting pipelines.

Note. The vapor recovery system is described in a separate subsection (see Evaporative Emission System), since it only serves to fulfill environmental requirements to reduce toxicity.

Functional purpose fuel supply systems – ensuring the supply of the required amount of fuel to the engine in all operating modes. The engine is equipped with an electronic control system with distributed fuel injection. In the distributed fuel injection system, the functions of mixture formation and dosing of the air-fuel mixture supply to the engine cylinders are separated: the injectors carry out metered fuel injection into the intake pipe, and the amount of air required at each moment of engine operation is supplied by the throttle assembly. This control method makes it possible to ensure the optimal composition of the combustible mixture at each particular moment of engine operation, which allows obtaining maximum power with the lowest possible fuel consumption and low exhaust gas toxicity. The fuel injection system and the ignition system are controlled by an electronic engine control unit, which continuously monitors the engine load, the vehicle speed, the thermal state of the engine, and the optimization of the combustion process in the engine cylinders using appropriate sensors.

A feature of the injection system of the Opel Astra J car is the synchronism of the operation of the nozzles in accordance with the valve timing (the engine control unit receives information from the phase sensors). The control unit turns on the nozzles sequentially, and not in pairs, as in asynchronous injection systems. Each nozzle is activated through 720°of crankshaft rotation. However, in starting and dynamic modes of engine operation, an asynchronous method of fuel supply is used without synchronization with the rotation of the crankshaft.

The main sensor for ensuring an optimal combustion process is control oxygen concentration sensor in exhaust gases (Lambda probe). It is installed in the exhaust manifold of the exhaust system, combined with the exhaust gas converter (collector), and together with the engine control unit and injectors forms a control loop for the composition of the air-fuel mixture supplied to the engine. Based on the sensor signals, the engine control unit determines the amount of unburned oxygen in the exhaust gases and, accordingly, evaluates the optimal composition of the air-fuel mixture entering the engine cylinders at any given time. Having fixed the deviation of the composition from the optimal 1:14 (fuel/air), providing the most efficient operation of the catalytic converter of exhaust gases, the control unit changes the composition of the mixture using injectors. Since the oxygen concentration sensor is included in the feedback circuit of the engine control unit, the air-fuel ratio control loop is closed.

A feature of the engine management system of the Opel Astra J car is that, in addition to the control sensor, a second, diagnostic oxygen concentration sensor, installed in the exhaust pipe of the exhaust system. According to the composition of the gases that have passed through the converter, it determines the efficiency of the engine control system. If the engine control unit, according to the information received from the diagnostic oxygen concentration sensor, detects an excess of exhaust gas toxicity that cannot be eliminated by calibrating the control system, then it turns on the warning light in the instrument cluster for exceeding the exhaust gas toxicity standards and stores the error code in memory for subsequent diagnostics.

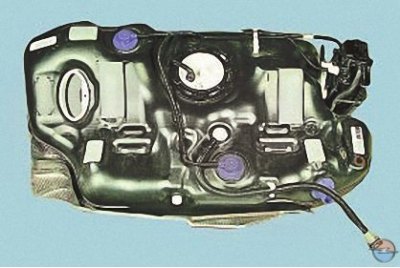

Fuel tank, molded from a special impact-resistant plastic, is installed under the floor of the body in its rear part and is attached with clamps. so that fuel vapors do not enter the atmosphere, the tank is connected by a pipeline to the adsorber of the fuel vapor recovery system. An electric fuel pump is installed in the flanged hole in the upper part of the tank; branch pipes are made in the rear part for connecting a filling pipe and a ventilation hose. From the pump, which includes a fuel filter, fuel is supplied to the fuel rail mounted on the engine intake pipe. From the fuel rail, it is injected by injectors into the intake pipe.

Fuel lines combined power systems in the form of interconnected steel pipelines and plastic hoses.

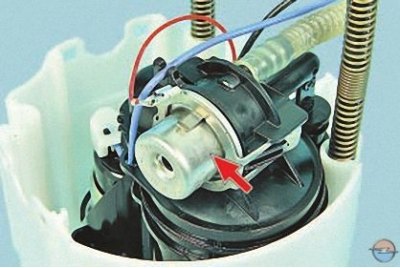

fuel module includes electric pump, fuel pressure regulator, fuel filter and fuel gauge sensor.

The fuel module delivers fuel and is installed in the fuel tank, which reduces the chance of vapor lock as the fuel is supplied under pressure rather than vacuum. Lubrication and cooling of the fuel pump parts are also improved.

The fuel pump is submersible, rotary type, with an electric drive.

Fuel pressure control installed in the fuel module and designed to maintain constant fuel pressure in the fuel rail. The regulator is connected to the beginning of the supply line (immediately after the fuel filter) and is a bypass valve with a spring, the force of which is strictly calibrated.

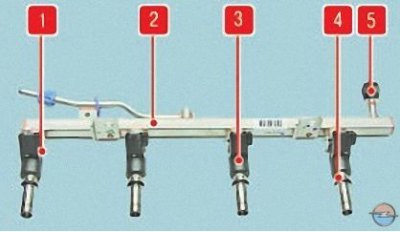

fuel rail 2 (pic. 1) is a hollow part with holes for injectors 3, with a fitting for connecting a high-pressure fuel line, a diagnostic fitting 5 for checking fuel pressure and brackets for attaching to the intake pipe. The injectors are sealed in the openings of the ramp and in the sockets of the intake pipe with rubber rings 4 and secured with spring clips 1. The assembly with the injectors is inserted into the openings of the inlet pipe with the injector shanks and secured with two bolts.

Pic. 1. Fuel rail: 1 - nozzle lock; 2 - ramp; 3 - nozzle; 4 - nozzle sealing ring; 5 - diagnostic fitting

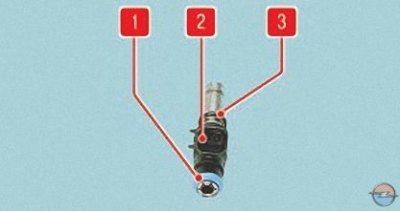

nozzles (pic. 2) attached to the ramp from which fuel is supplied to them, and with their atomizers they enter the openings of the intake pipe.

Pic. 2. Fuel injector: 1 - top sealing ring; 2 - plug terminals of the electromagnet winding; 3 - lower sealing ring

In the openings of the ramp and the intake pipe, the nozzles are sealed with rings 1 and 3. The nozzle is designed for metered injection of fuel into the engine cylinder and is a high-precision electromechanical valve. Pressurized fuel flows from the rail through channels inside the nozzle body to the shut-off valve. A spring compresses the check valve needle against the opening of the atomizer plate, holding the valve in the closed position. Voltage supplied from the engine control unit via plug-in terminals 2 on the winding of the injector electromagnet, creates a magnetic field in it, which draws the core, together with the needle of the shut-off valve, into the electromagnet. The annular hole in the atomizer plate opens and fuel is injected through the holes in the atomizer body into the intake port of the cylinder head and further into the engine cylinder. After the termination of the electrical impulse, the spring returns the core and the needle of the shut-off valve to its original state - the valve is closed. The amount of fuel injected by the injector depends on the duration of the electrical impulse.

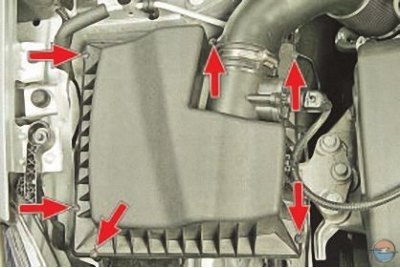

Air filter installed in the right front of the engine compartment on the engine mudguard. The filter inlet pipe is connected to an intake noise resonator installed under the right front fender, which, in turn, is connected to an air duct installed under the upper cross member of the radiator frame.

Rubber corrugated air inlet sleeve connects the filter to the throttle assembly.

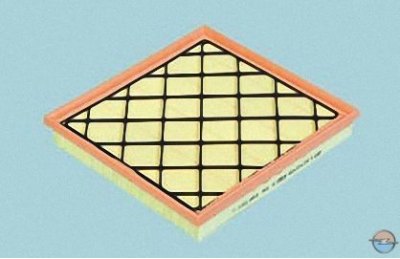

Air filter element paper, flat, with a large area of the filtering surface.

Throttle assembly, which is the simplest control device, designed to change the amount of main air supplied to the engine intake system, is installed on the inlet flange of the intake pipe and is bolted. A molded rubber air supply sleeve is put on the inlet pipe of the throttle assembly, fixed with a clamp and connecting the throttle assembly with the air filter.

The throttle assembly includes a throttle position sensor and a throttle control stepper motor. There is no mechanical connection between the throttle assembly and the throttle control pedal. So-called «electronic» the throttle control pedal transmits information about the degree of depression on the pedal to the electronic engine control unit, which, in turn, taking into account the speed of the car, the gear engaged, the engine load and the speed of its crankshaft, opens the throttle valve to the required angle.

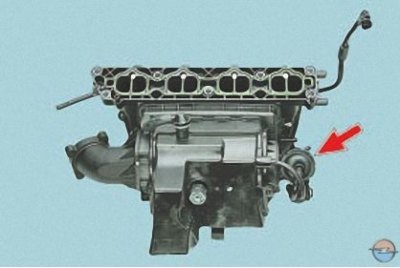

intake pipe equipped with a system for changing the length of the intake tract, which allows you to develop increased power at high engine speeds (minimum intake tract length) and maximum torque in the low and medium speed range (increased length of the intake tract). The length is changed by a signal from the engine control unit by turning the flap inside the intake pipe using a pneumatic chamber (shown in the photo with an arrow), which is connected to the engine vacuum system through a solenoid valve.

Visitor comments