You will need: end head «at 15», universal puller, bearing press-in tool, flat-blade screwdrivers, punch, hammer.

1. If the teeth of the speedometer drive gear are heavily worn, replace the gear. To do this, spread the ends of the retaining ring with a screwdriver and at the same time, with a second screwdriver, slide the gear together with the ring along the trunnion of the differential box.

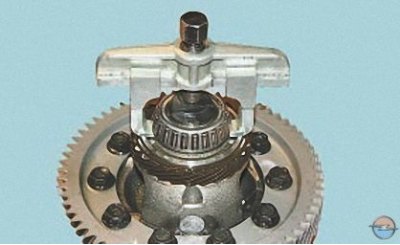

2. To replace a worn or damaged bearing, press it off the differential box trunnion.

Attention!

- A bearing pressed in the manner shown is not suitable for re-installation, as its separator is damaged. Therefore, do not dismantle the differential bearings unnecessarily.

- When replacing differential bearings, be sure to replace their outer races installed in the adjusting nut and bearing cap (see Disassembly and assembly of the gearbox, troubleshooting of its parts).

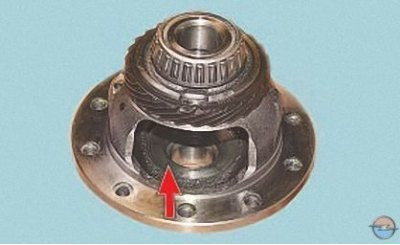

3. Turn out ten bolts of fastening of a conducted gear wheel of the main transfer to a differential box.

4. Mark the relative position of the gear and box..

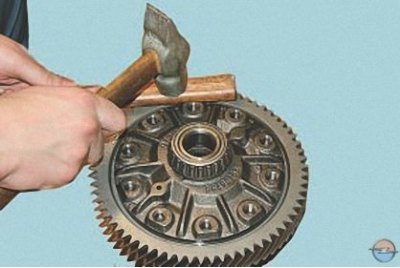

5.... press the gear from the differential box with light hammer blows through the wooden spacer..

6.... and remove the gear.

7. Knock out the fixing pin of the axis of the satellites with a beard with a diameter of 3.2 mm..

8.... and remove the satellite axle from the differential box.

9. Turning the differential gears, remove the satellites from the differential box..

10.... and side gears.

Note…

...on satellites..

... and side gears are equipped with support washers. When reassembling, do not forget to install them in their original places.

11. Inspect the working surfaces and teeth of satellites, splines and teeth of side gears. In case of severe wear of the working surfaces, splines and teeth, as well as when the teeth are chipped, replace the differential gears.

12. Inspect the gear bearing washers. Replace the washers if they are visibly worn

13. Inspect the surfaces of the differential box in the places where the gear support washers work. In case of severe wear of the surfaces, replace the differential box.

14. Remove small irregularities on the necks of the axis of the satellites with fine-grained sandpaper. When enveloping the satellites on the metal necks or when they are worn on one side, replace the axle.

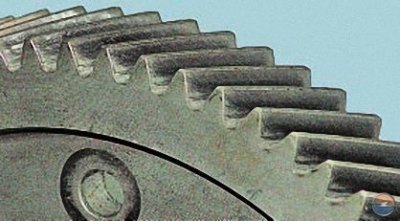

15. In the presence of chips, chipping and significant development of the teeth of the driven gear of the final drive, replace the gear.

Note. When replacing the final drive gear, the drive gear must also be replaced at the same time (output shaft), since these gears are selected by noise and installed only in pairs.

16. Assemble the differential in the reverse order of disassembly, taking into account the following:

- press the fixing pin of the axis of the satellites into the hole of the differential box from the side into which it was knocked out;

- press the differential bearings onto the trunnions of the differential box, applying force to the inner ring;

- before pressing onto the pin of the differential box of the speedometer drive gear, heat the gear in an oil bath to a temperature of 80°C;

- press the driven gear of the final drive onto the differential box, aligning the marks made during disassembly and heating the gear in an oil bath to a temperature of 100°C;

- lubricate the threaded part of the driven gear mounting bolts with an anaerobic thread locker, tighten the bolts evenly in a cross pattern. Finally tighten the bolts to 70 Nm (7.0 kgf·m).

Visitor comments