Spontaneous disengagement of gears indicates wear or damage to the teeth of the synchronizer clutch and gear rims.

Synchronizers I and II, as well as III and IV gears are the same in design, so they are repaired using the same methods.

You will need a screwdriver.

1. Before disassembly, mark the position of the coupling relative to the hub.

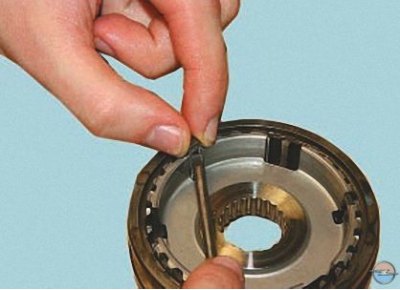

2. Prying with a screwdriver..

3.... remove two springs

Note. The second spring is not visible in the photo, as it is located on the reverse side of the synchronizer.

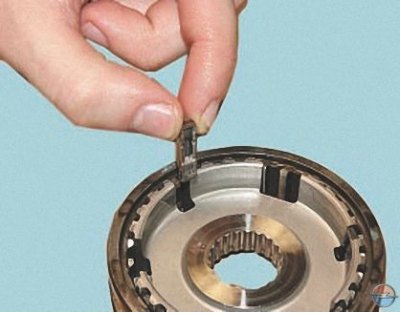

4. Prying with a screwdriver..

5.... remove three crackers from the grooves of the hub..

6.... and remove the coupling from the hub.

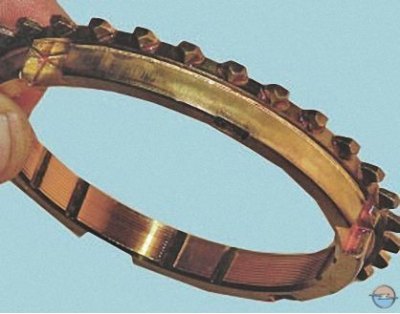

7. Inspect the synchronizer parts. Springs should not show signs of wear at the points of contact with crackers.

8. Crackers should not be deformed, and the locking tabs of the crackers should be significantly worn out.

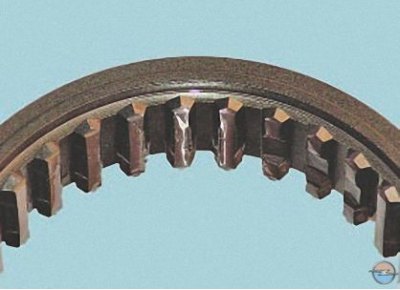

9. At the ends of the splines of the coupling..

10.... and the blocking rings should not be chipped or jammed.

11. There should be no nicks on the splines and no signs of wear on the hub.

12. When installing the blocking ring on the cone of the corresponding gear, the gap between the ends of the rims of the ring and the gear must be at least 1 mm, otherwise replace the blocking ring.

13. Assemble the synchronizer in the reverse order of disassembly, installing the clutch on the hub in accordance with the marks made before disassembly.

Visitor comments