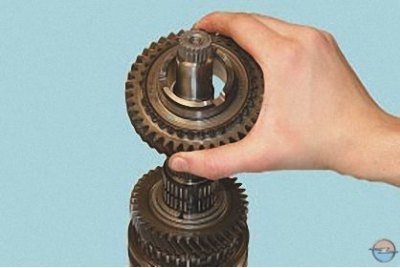

1. Press the rear bearing off the secondary shaft...

2.... and remove it.

3. Remove, by squeezing the antennae, the snap ring..

4.... support washer..

5....thrust needle bearing..

6.... the driven gear of the 1st gear..

7.... the needle bearing of the driven gear of the 1st gear..

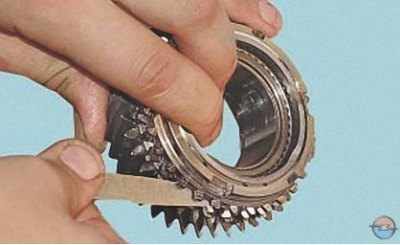

8. … inner blocking ring…

9.... intermediate ring..

10.... and the outer blocking ring of the synchronizer of the 1st gear.

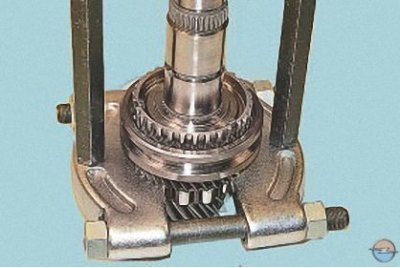

11. Opening with a puller..

12.... remove the retaining ring..

13.... and a thrust washer.

14. Press the synchronizer of I and II gears from the splines of the shaft together with the driven gear of the II gear, applying force to the end of the gear..

15.... and remove the synchronizer from the shaft.

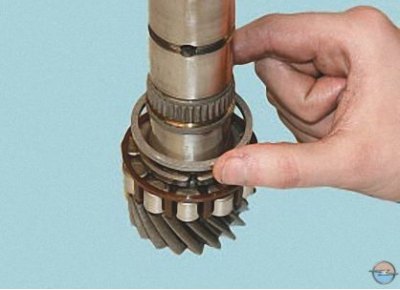

16. Remove the outer blocking ring, intermediate ring..

17.... the inner blocking ring of the synchronizer of the 2nd gear..

18.... and the second gear driven gear.

19. Remove the 2nd gear driven gear needle bearing.

20. Remove locking ring..

21.... and two persistent half rings.

22. Remove the third gear driven gear from the shaft..

23.... the needle bearing of the driven gear of the third gear..

24.... and the third gear synchronizer blocking ring.

25. Having unclenched the retaining ring of the hub of the synchronizer of III and IV gears with a puller..

26.... remove the retaining ring from the shaft..

27.... and a thrust washer.

28. Press the synchronizer of III and IV gears from the splines of the shaft, applying force to the end face of the driven gear of the IV gear.

29. Remove the synchronizer of III and IV gears from the shaft..

30.... synchronizer blocking ring..

31.... the driven gear of the IV gear..

32.... and a split needle bearing of the driven gear of the IV gear.

33. Remove the locking ring from the shaft..

34.... two half rings..

35.... and the rear roller bearing of the secondary shaft.

36. Inspect the output shaft and its parts:

- on the necks for needle bearings there should be no signs of fatigue damage, and on the slots for installing synchronizer couplings - nicks and crushing;

- on persistent half rings and locking rings there should be no signs of wear and scoring on the end surfaces;

- on the hubs of the synchronizers there should be no nicks and signs of wear;

- at the ends of the splines of the synchronizer couplings and blocking rings there should be no jamming and chipping;

- when installing the synchronizer blocking ring on the cone of the corresponding gear, the gap between the ends of the ring and the ring gear of the gear must be at least 1 mm. Otherwise, replace the blocking ring.

37. Assemble the output shaft in the reverse order of disassembly, taking into account the following:

- before pressing onto the shaft, heat the synchronizer hubs in an oil bath to a temperature of 100°C;

- when pressing on the synchronizer hubs, make sure that the crackers get into the grooves of the blocking rings;

- after assembling the output shaft, check the rotation of all gears: they must rotate freely.

Visitor comments