Bleed the brake system while wearing goggles. If brake fluid accidentally gets into your eyes, rinse immediately with plenty of water and seek medical attention!

Bleeding the hydraulic system is carried out in order to remove air from it that enters the tract when servicing the brake mechanisms, replacing hydraulic lines or GTZ, as well as when lowering below the minimum allowable value of the fluid level in the master cylinder reservoir.

1. If air has entered the system due to a drop in the liquid level in the GTZ tank, or when the brake lines are disconnected from the GTZ, the brake mechanisms of all four wheels must be pumped. When disconnecting the lines from any of the calipers/wheel cylinders, it will be enough to pump only this particular brake mechanism.

2. If the brake line was disconnected from the fitting located between the GTZ and one of the brake mechanisms, only this part of the brake circuit is pumped.

3. Depress the foot brake pedal several times with the engine off to release the residual vacuum in the vacuum brake booster.

4. Remove the cap from the GTZ reservoir, pour fresh liquid into the reservoir if necessary, then place polyethylene under the cap and screw it into place.

Remember to check the fluid level in the reservoir regularly while pumping. An excessive drop in the level is fraught with air entering the GTZ, which will nullify all the efforts made and entail the need to pump the entire brake system.

The main method of pumping - the help of an assistant is required

1. Enlist the help of an assistant, prepare a supply of fresh brake fluid, a transparent vessel partially filled with brake fluid, a piece of plastic hose that fits tightly over the bleed valve, and a suitable open-end / ring wrench to release / tighten the valve.

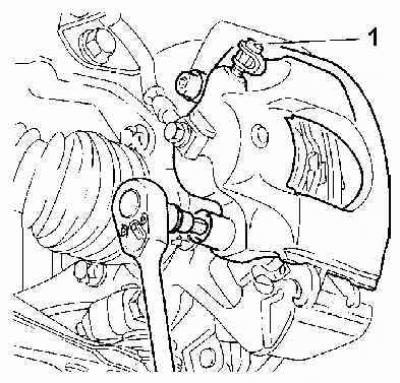

2. Remove the dust cap and slightly loosen the right rear brake bleed valve, then tighten it again so that it releases quickly and easily during the procedure.

bleed valve (1) brake caliper is equipped with a dust cap

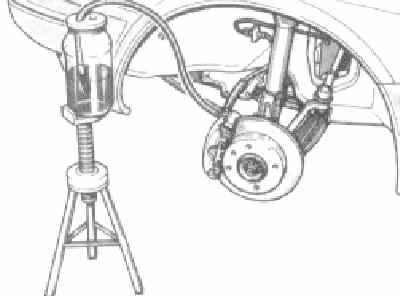

3. Pull a suitable plastic or rubber hose over the valve, lower the other end into a transparent vessel partially filled with clean brake fluid. The end of the hose must be completely immersed in the liquid.

Make sure that the other end of the hose connected to the bleeder valve is completely immersed in the brake fluid poured into a transparent receiving vessel

4. Ask an assistant to slowly depress the foot brake pedal several times, thereby raising the pressure in the system.

5. With the brake pedal fixed in the lower position, slightly open the bleed valve so that brake fluid begins to be forced out of it. Watch for fluid exiting the hose. After a couple of seconds, when the pressure weakens, close the valve and allow the assistant to release the pedal.

6. Repeat the procedures of the last two paragraphs until fluid free from air bubbles begins to flow from the valve, then go to the brake mechanism of the left rear wheel. Proceeding in a similar manner, pump this mechanism, then the mechanisms of the right front and, finally, the left front wheels.

Always make sure that the liquid level in the GTZ reservoir does not drop too low!

7. Never add used brake fluid to the reservoir - it is highly hygroscopic and absorbs a lot of moisture over time, which leads to a drop in its boiling point and, as a result, to a decrease in braking efficiency. In addition, the presence of moisture in the hydraulic system contributes to the accelerated aging of the material of flexible brake hoses.

Bleeding Method Using Check Valve Kit

As the name suggests, the bleed kit includes a piece of hose equipped with a one-way valve. The valve prevents the ejected fluid from returning back to the system and will allow one-man pumping - do not forget to monitor the fluid level in the master cylinder reservoir (the level must not fall below the MIN·mark!).

Pumping with compressed air

A spare wheel can be used as a source of compressed air - you must first relieve its inflation pressure. Proceed in accordance with the instructions supplied with the kit.

When using such a device, you only need to release the bleed valve and wait for the air bubbles to stop leaving the tract.

The main advantage of this method is that the large reservoir of hydraulic fluid included in the kit does not allow air to be sucked into the tract during pumping.

All Methods

1. Upon completion of pumping, add fresh brake fluid to the GTZ reservoir, bringing its level back to normal.

2. Check up efficiency of functioning of brakes. When depressing the pedal, it should provide firm resistance - a feeling of softness of its stroke indicates the presence of air in the hydraulic circuits and the need to repeat the pumping procedure.

In no case do not start operating the car without being absolutely sure that the brake system is working properly!

Visitor comments