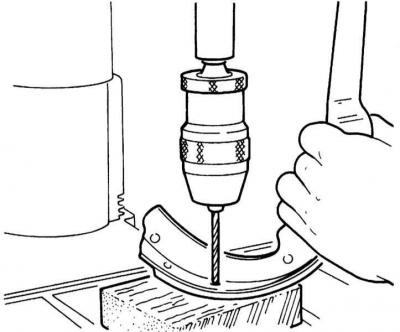

2. Drill out the brake lining rivets and knock them out.

Drilling out brake lining rivets

3. Brake linings are available in two thicknesses:

- Overlays of normal thickness (5 mm) can be installed immediately after riveting and are not used for machined brake drums.

- Overlays of increased thickness (5.6mm) are installed if the brake drum has been previously machined. Brake linings after riveting should be rubbed with a grinder with a radius of 0.2 mm less than the radius of the machined brake drum.

4. Thoroughly clean the mating surfaces of the brake shoes.

Do not apply adhesive between brake linings and drum.

5. Rivet the brake linings to the shoes.

Insert the rivets from the outside through the brake shoe and rivet them from the inside. Make sure that the head of the rivet is clean, even and lies evenly on the brake shoe.

6. When riveting a new lining, start from the middle.

Make sure that the pads are evenly attached to the shoes and have no gap anywhere.

7. Install the brake shoes.

Visitor comments