Removing

Engines 1.4 and 1.6 l

1. Remove the toothed belt (see Section Removing and installing timing belt (engines 1.4 and 1.6 l)) .

2. Remove the camshaft gears (see Section Removal and installation of gear wheels of crankshaft and camshafts and intermediate rollers (engines 1.4 and 1.6 l)) .

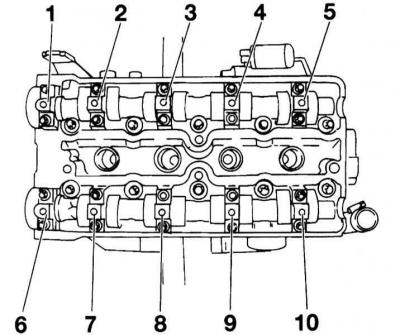

3. First remove the following bearing caps: 1, 3, and 5 for the intake camshaft and 6, 8, and 10 for the exhaust camshaft. Loosen all the bolts of the specified covers crosswise, first by half a turn, then by one turn and then turn out completely. Remove bearing caps.

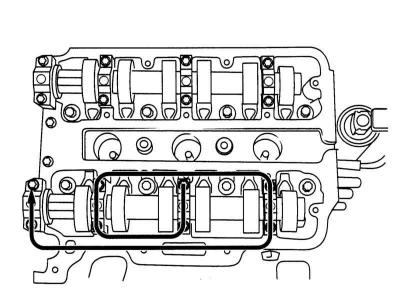

Camshaft bearing cap numbering

4. Then unscrew the cap screws 2 and 4 and 7 and 9 in the same way.

5. Remove the camshaft, evenly removing it from the bearings.

6. Carefully remove both glands from their seats.

Engines 1.0 and 1.2 l

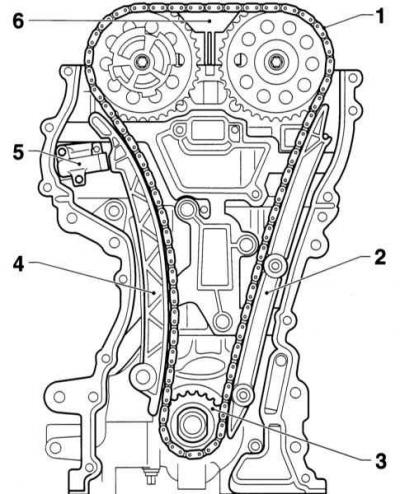

Timing drive components are presented in the accompanying illustration.

Timing Drive Components

1 - Chain

2 - chain guide

3 - Asterisk

4 - Tension bar

5 - Tensioner

6 - spacer

Chain tension is provided by a spring-loaded, maintenance-free hydraulic tensioner. The drive chain in question must not be disconnected and locks must not be used to connect it.

1. Remove the timing case cover (see Section Removal and installation of a cover of the gas-distributing mechanism) and timing cover (see Section Removal and installation of a head of cylinders).

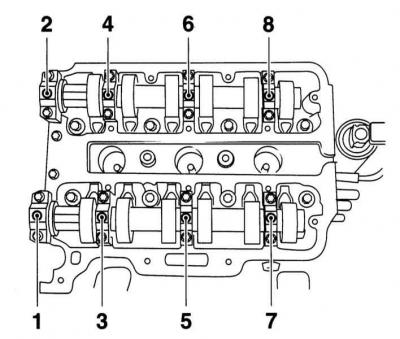

2. First give a quarter of a turn, and then one turn, the bolts securing the bearing caps 2 and 8 of the intake camshaft, and then the bearing caps 1 and 7 of the exhaust camshaft, then completely unscrew the bolts.

Camshaft bearing cap numbering

When removing the bearing caps, pay attention to the designation. Do not mix them up during installation.

3. Then unscrew the bearing cap bolts 4 and 6 and respectively 3 and 5 in the same way. Remove the camshafts evenly from the bearings.

Examination

1. Carefully examine the condition of the bearing journals and camshaft cams. Replace shaft if scored or scratched. Also check the condition of the working surfaces of the plain bearings in the bearings of the gas distribution mechanism housing; in case of defects that cannot be eliminated, it will be necessary to replace the cylinder head.

2. Alternately laying the camshafts in prisms, using a plunger-type dial gauge, determine the amount of their radial runout (on bearing journals). When the measurement results are out of range (see Specifications in Chapter Engines) the camshaft must be replaced.

Installation

Engines 1.4 and 1.6 l

1. Lubricate the friction surfaces of the hydraulic valve lifters with a thin layer of MoS2 grease.

2. Lubricate the sealing surfaces of the outer camshaft bearing caps (from the toothed belt) on the cylinder head with sealant, for example, OPEL 15 04 201.

3. Carefully install the camshaft.

4. Tighten alternately crosswise in several stages the bolts of the bearing caps 2 and 4 of the intake camshafts, as well as the bearing caps 7 and 9 of the exhaust camshafts.

The markings on the camshaft bearing caps must match the markings on the cylinder head.

5. Install bearing caps 1, 3 and 5 and 6, 8 and 10 in the same way.

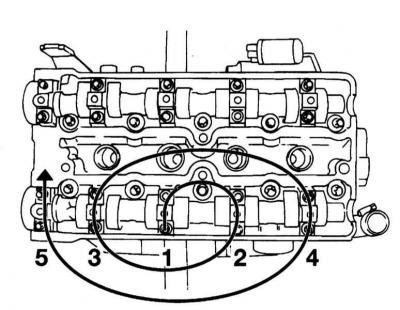

6. Tighten the camshaft bearing cap bolts in a spiral pattern as shown in the accompanying illustration, with effort 8 Nm.

The procedure for tightening the camshaft bearing caps

7. Install the shaft seals using the appropriate tool. Lubricate the seal lip with clean engine oil first.

8. Install the camshaft gears (see Section Removal and installation of gear wheels of crankshaft and camshafts and intermediate rollers (engines 1.4 and 1.6 l)) .

9. Install the toothed belt (see Section Removing and installing timing belt (engines 1.4 and 1.6 l)) .

Engines 1.0 and 1.2 l

1. First, alternately, in several approaches, screw in the bolts for fastening the bearing caps 4 and 6, then 3 and 4. Do not tighten the bolts.

2. Then screw in the bearing cap bolts 2 and 8, then 1 and 7 in the same way.

3. Tighten the camshaft bearing cap bolts in a spiral from the inside to the outside with a force 8 Nm.

The procedure for tightening the camshaft bearing caps

Visitor comments