A damaged injector can also be determined by sequentially loosening the union nuts of the fuel lines on the injectors while the engine is running at high idle. If the number of revolutions does not change after loosening a union nut, this indicates a defect in the corresponding injector. You can also identify a damaged nozzle using a pressure gauge at a service station.

Signs of injector damage are:

- Lack of ignition;

- Detonation in one or more cylinders;

- Engine overheating;

- Reduced engine power;

- Excessively black exhaust;

- Increased fuel consumption.

Removing

1. Remove the air filter.

2. Turn out bolts of fastening and remove a final collector.

3. Clean fuel lines.

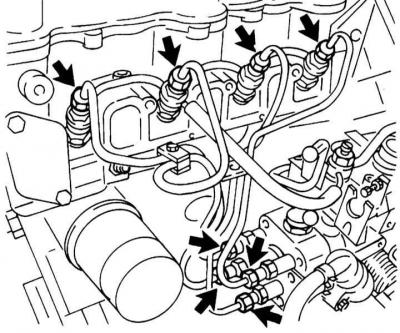

4. Give captive nuts of fuel lines and remove them as a set.

Nuts of fastening of pipelines

Do not change the shape of the fuel lines.

5. Disconnect the fuel return lines.

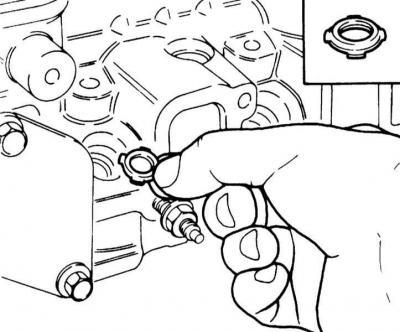

6. Unscrew the nozzle holder together with the nozzle using a special tool OPEL KM-728.

7. Remove the O-ring and shaped washer.

Nozzle O-ring

Installation

1. Place a new sealing ring and a new shaped washer in the hole for the nozzle in the cylinder head.

The convex part of the washer should look up.

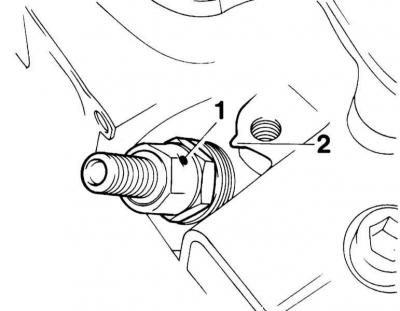

2. Insert the nozzle into the hole so that the mark (1) on the injector matched the mark (2) on the cylinder head.

Mounting marks

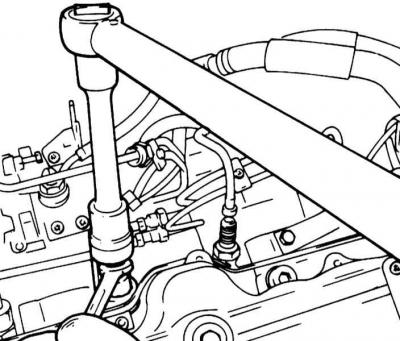

3. Tighten the union nut with the OPEL KM-728 special tool. At the same time, hold the nozzle holder against turning with a wrench.

Tightening the union nut of the injector

In this case, the nozzle should not rotate, and the marks should match.

4. Install fuel return lines with new gasket and torque nut 30 Nm.

5. Install the fuel lines to the injectors and injection pump and tighten the union nuts with force 25 Nm.

6. Install the inlet pipeline with a new gasket and tighten the mounting bolts with force 25 Nm.

Visitor comments