Attention: For dismantling of a shock-absorber rack use only serviceable tool. Never unscrew the shock absorber nut unless the spring is securely compressed with a special tool! To avoid an accident, do not use a wire to hold the spring in a compressed position! Make sure that the shock absorber is securely fixed in the vise so that the device cannot slip out!

1. Remove shock absorber (see section 2).

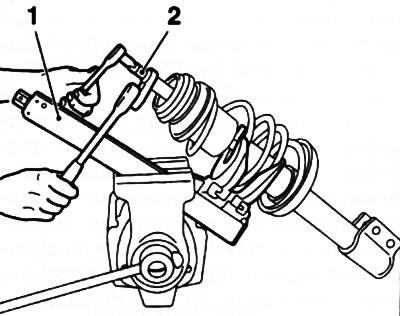

2. Compression of coil springs should only be done with the help of special tools (for example, Hazet 4900-2A with clamping plates MKM-6068-10). Clamp the fixture in a vise and install the shock absorber assembly in it so that at least 3 turns of the helical spring are compressed (see resist. illustration). Compress the coil spring, completely removing the load from the support bearing. Track the reliability of the fit of the device on the spring.

3.2. Coil Spring Compressors (1) and for releasing the support bearing fastening nut (2)

3. Holding the shock absorber rod with a wrench, unscrew the upper support bearing fastening nut (see illustration 3.2).

4. Remember the installation position of the elements of the shock absorber assembly, if necessary, mark their position with a marker (see illustration 2.1) and disassemble the rack into elements.

5. Inspect the components for mechanical damage, check the smoothness of the shock absorber rod. Replace failed components.

6. Examine the strut shock absorber for signs of leak development. Make sure that there are no signs of corrosion development on the rod along its entire length, as well as signs of mechanical damage. Holding the shock absorber vertically, check the correct operation of its operation, both at full and short (50-100 mm) stroke of the stock. In both cases, the resistance should be soft, even and constant. If signs of a malfunction are detected, both shock absorbers should be replaced.

7. Release the spring from the fixture and carefully inspect it for signs of deformation and mechanical damage. If necessary, replace both front suspension springs. Depending on the model, springs of different stiffness can be installed. Their designation is carried out by color marking on one of the turns - the same springs must be installed on both racks. Springs that have sagged and do not develop proper force are also subject to replacement.

Note: New springs have a protective lacquer coating against corrosion - take care not to damage it during installation.

8. Check the condition of other rack assembly components. Replace failed parts.

9. Installation is made in an order, the return to an order of removal. When installing the spring, make sure that it is correctly positioned on the lower support washer. Screw a new nut onto the shock absorber rod and, holding the rod from turning, tighten it to the required torque.

Visitor comments