Note: On models equipped with an OBD II self-diagnosis system, there should be an entry on the nameplate under the hood or at the bottom of the instrument panel «OBD II compliant».

1. With the introduction of the requirements of the latest environmental legislation, the requirements for controlling the content of toxic waste in exhaust gases have become more stringent. This in turn led to the equipment of cars with more advanced engine management systems. The main element of the system is the onboard processor, often called the electronic control module (ECM).

2. The models described in this manual are equipped with a second generation on-board diagnostic system (0BD-II), which allows you to check sensors and actuators, controls vehicle maintenance cycles, provides the ability to store even short-term failures during operation and clear the memory block. Reading the processor memory data is performed using a special scanner connected to the 16-pin diagnostic connector for reading the database (DLC).

3. Before connecting diagnostic tools, make sure that the battery is in good condition and full of charge and perform other checks listed in Chapter 4, Section 11.

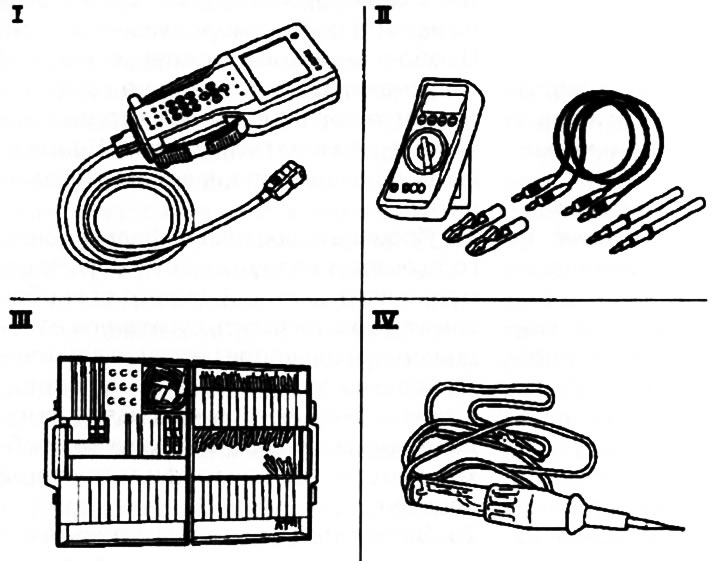

4. Information is taken using diagnostic equipment (see resist. illustration). It should be remembered that, as a rule, such equipment is designed for a specific model or range of cars, changing the control system by at least one element leads to a change in all electrical circuits - it is recommended to contact the Opel service station for diagnostics.

3.4. Diagnostic devices (The kit also includes a vacuum gauge - not shown in the figure): I - Main diagnostic tool TESN-2 with adapters; II - Digital meter (multimeter); III - Electronics kit; IV - Probe

5. Some manufacturers have launched scanners designed for use by amateur mechanics at home - ask in car accessories stores. Service stations can use an expensive specialized diagnostic computer, specially designed for a complete diagnosis of most modern car systems. Diagnostic scanners and computers allow you to read and print diagnostic codes, as well as circuit diagrams of electrical equipment stored in the memory of the control module (if any), program the anti-theft system, observe the signals in the fuse circuits in real time.

6. If a malfunction is detected, the ECM issues a command to turn on the warning lamp mounted in the instrument panel «Check engine», also called the failure indicator (MIL). At the same time, the control unit switches to emergency mode. The lamp will continue to burn until the memory of the self-diagnosis system is cleared of the fault codes entered in it (see below).

7. Reading the data of the OBD-II system is carried out using a special scanner TESN-2 (see illustration 3.4), connected to the 16-pin diagnostic connector (DLC) using an adapter - follow the instructions in the device menu. The list of codes of the main malfunctions of the power unit is given in the Specifications at the beginning of this Chapter. With the help of the same scanner, the processor memory is also cleared. It is recommended that the procedures for reading DTCs and clearing the ECM memory be entrusted to a workshop.

8. Engine management/emission control system components are subject to a special extended warranty. Do not attempt to diagnose ECM failures or replace system components yourself before this commitment expires - contact Opel for information.

Visitor comments