2. The clutch is released hydraulically. The shutdown drive consists of a clutch pedal, a main hydraulic cylinder with a reservoir, connecting lines and an executive cylinder combined with a release bearing, planted directly on the input shaft of the gearbox (see illustration 1.1). Note: The reservoir is shared between the clutch actuators and the service brake system.

3. Models with Easytronic have drive and layout features. The clutch of these models is equipped with a control module (see resist. illustration) and a separate reservoir for hydraulic fluid.

4. When the corresponding pedal is depressed, hydraulic pressure rises in the system path, which as a result is applied to the release bearing mounted in the slave cylinder. The bearing, under the influence of hydraulic force, is pressed against the petals of the diaphragm spring of the pressure plate in the clutch basket. Bending, the spring breaks the contact of the pressure and driven discs, releasing the latter.

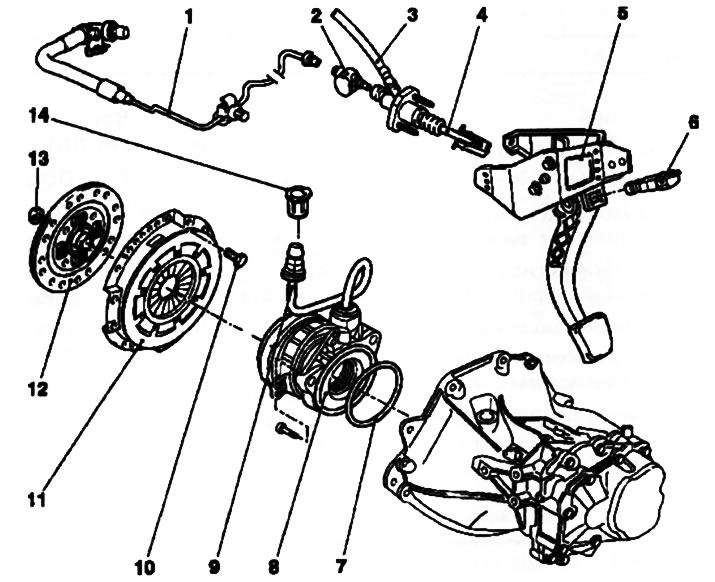

1.1. The design of the clutch and its drive components: 1. Hydraulic line for the clutch release drive path; 2. Damper; 3. Hose connecting the master cylinder to the tank; 4. Push rod of the clutch master cylinder; 5. Clutch pedal bracket; 6. Clutch pedal position switch (models with tempostat); 7. O-ring; 8. Assembling the clutch slave cylinder with release bearing; 9. Hydraulic line; 10. Bolt of fastening of the clutch basket; 11. Assembling the clutch basket with the pressure plate; 12. Slave (friction) clutch disc; 13. Guide sleeve; 14. Union nut

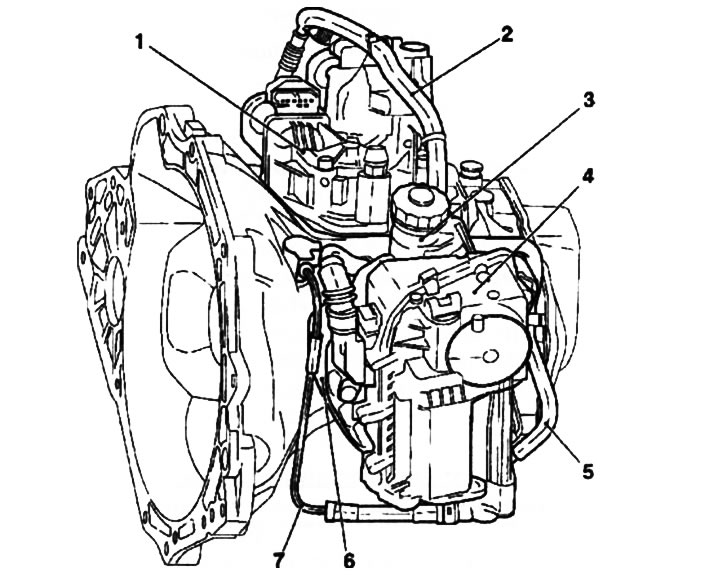

1.3. Easytronic system layout: 1. Gearshift module; 2. Cable channel of the Easytronic system; 3. Brake fluid reservoir; 4. Clutch control module; 5. Clutch hydraulic line supply hose; 6. Mounting plate for the clutch control module; 7. Return hydraulic line

Visitor comments