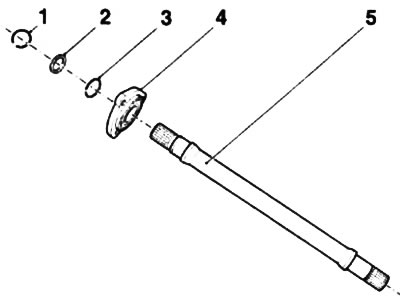

1.1. Intermediate shaft design (diesel models - 1.7 l): 1, 3. Retaining rings; 2. O-ring; 4. Support flange of the intermediate shaft; 5. Intermediate shaft

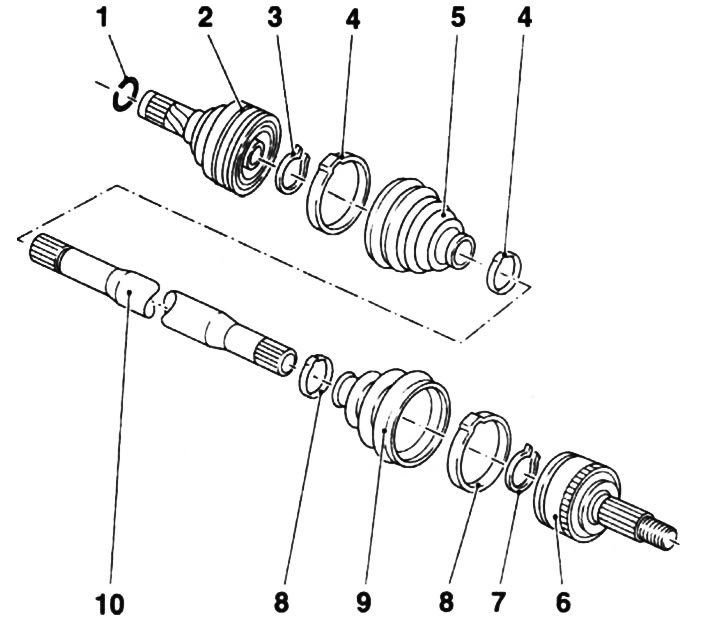

2. Each of the drive shafts is equipped with internal and external constant velocity joints (SHRUS). Most of the models discussed in this manual are equipped with double compensation CV joints (see resist. illustration). On models equipped with a 1.0 liter engine, internal tripod-type CV joints can be installed on the drive shafts - some features of their design are discussed in Sections 5 and 6.

1.2. The design of the drive shaft assembly with double compensation CV joints: 1. Retaining ring; 2. Internal CV joint; 3, 7. Internal retaining ring of the hinge; 4, 8. Mounting clamps; 5, 9. Anthers; 6. External CV joint; 10. Drive shaft

3. The trunnions of the outer hinges are equipped with splines that provide articulation with the wheel hubs. On the outside of the hubs, the hinge pins are fixed with large hub nuts. The internal hinges are also slotted into a sliding connection with the side gears of the differential and are fixed with locking rings. intermediate shaft (with appropriate equipment) one of its ends is splined with the side gear of the differential, the other end of the shaft is fixed in the intermediate support (bracket) and is connected to the right drive shaft also using a spline connection.

Visitor comments