Turn on the hazard warning lights, apply the parking brake, on an automatic transmission put the shift lever in the P park position, on a manual transmission or Easytronic, shift into 1st gear or reverse.

Set up a warning triangle as required by law.

Remove the spare wheel from the trunk or from under the floor of the car.

Before lifting the vehicle, bring the front wheels to a straight position.

It is strictly forbidden to change several wheels at the same time.

Block the wheel diagonally opposite the wheel you are changing by placing wedges or similar objects in front of and behind the wheel.

In soft ground, place a strong pad under the jack with a maximum thickness of 1 cm.

Note. Using thicker pads may damage the jack and the vehicle.

Note. There must be no people or animals in the lifted vehicle.

Note. Do not get under a jacked up vehicle.

Note. Do not start the engine with the vehicle raised.

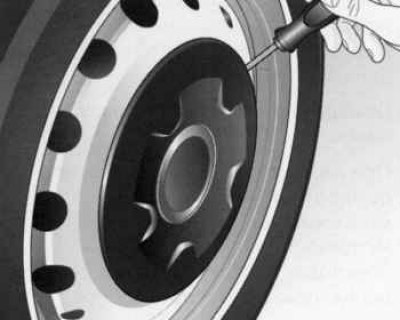

Unlock the wheel cap with a screwdriver and remove the cap. To do this, insert a screwdriver into the side recess of the wheel cap.

Remove the wheel cover with a hook.

On another version, the wheel cap is removed together with the wheel bolts.

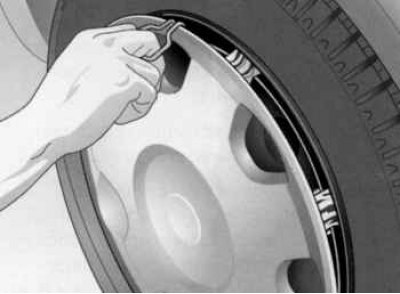

On alloy wheels: pry out the wheel cover with a screwdriver and remove the wheel cover by placing the screwdriver in the side recess of the cover.

Remove the bolt caps from the wheel bolts.

On alloy wheels with anti-theft protection: unscrew and remove the cap using the special wrench included in the tool kit.

Loosen the wheel bolts with a wheel bolt socket wrench while inserting the wrench all the way.

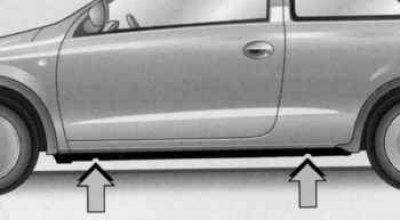

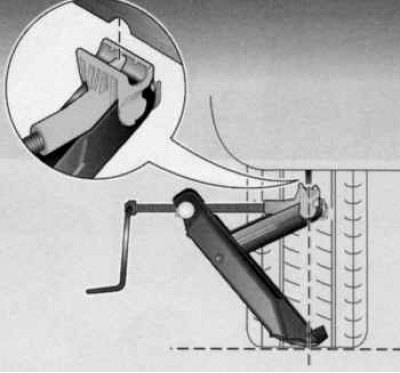

The markings on the bottom edge of the body indicate where the jack should be placed under the bottom of the vehicle.

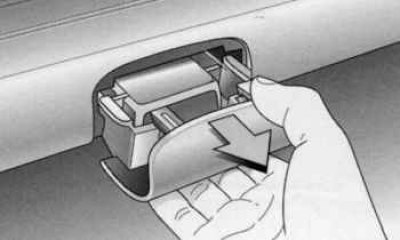

On some vehicle versions, the installation sites are covered with hatches - pull the hatches out.

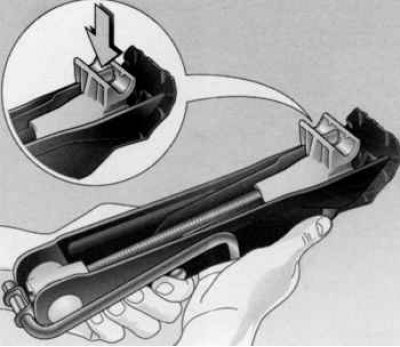

Before installing the jack, manually set the required height. Install the jack arm in front (or behind) so that the grip of the jack (indicated by the arrow in the figure) covered the vertical edge and entered the slot in it.

When turning the handle, make sure that the edge of the jack thrust bearing stands motionless on the ground vertically under the gripping point.

If the jacking pad is not exactly under the jacking point during jacking, immediately carefully lower the vehicle and repeat the jacking procedure.

Raise the vehicle by rotating the handle.

Remove the wheel screws and place them so that the threads are not dirty.

On another version, the wheel cap is removed together with the wheel bolts.

Replace wheel.

Screw in the wheel bolts and lightly tighten them, while inserting the socket wrench until it stops.

On the other version, first install the wheel cap and then tighten the wheel bolts.

Lower the car.

Tighten the wheel bolts firmly in a criss-cross pattern while inserting the socket wrench until it stops.

Before mounting the wheel cover, clean the wheel in the area of the clamp holders. The valve symbol on the back of the wheel cover must point to the wheel valve.

Fit and secure the cappak or wheel cover and respectively the wheel bolt covers.

On light-alloy wheels, install and fix the wheel cap, while inserting the pin on the back of the cap into the corresponding hole in the wheel.

On alloy wheels with anti-theft protection, install a wheel cover. Insert and screw in the anti-theft device.

Cover the place of installation of the jack on the bottom of the car with a cover. Remove the removed wheel. Remove the tool and warning triangle.

Check the tire pressure of the installed wheel, correct if necessary.

Using a torque wrench, check the torque of the wheel bolts on the installed wheel, correct if necessary.

Replace the replaced defective tire.

At the first opportunity, replace the installed emergency wheel with a normal one.

Visitor comments