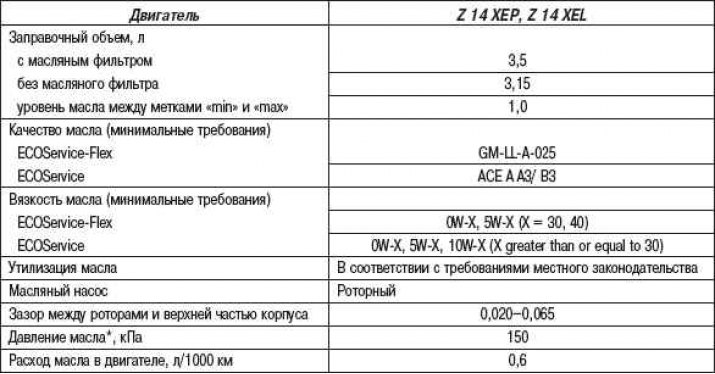

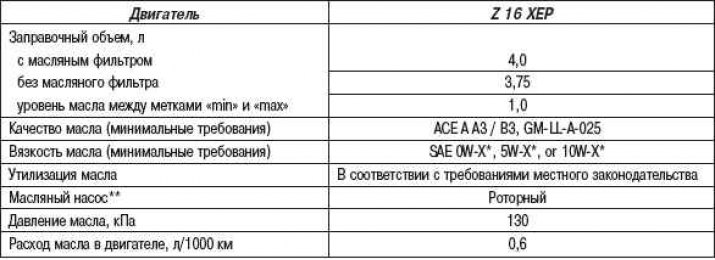

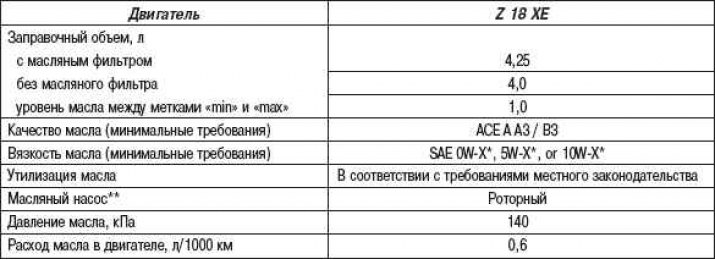

Lubrication system (engines 1.4 l)

Lubrication system (engines 1.6 l)

* «x» greater than or equal to 30.

** Engine warmed up and idling.

Lubrication system (1.8 l engines)

* «x» greater than or equal to 30.

** Engine warmed up and idling.

Removing

Before the test procedure, warm up the engine to operating temperature (oil temperature - 80°C).

Open the hood.

Loosen the fastening nut and disconnect the ground wire from the battery

Remove the air filter housing and intake manifold.

Disconnect the MAF sensor harness connector.

Unscrew the mounting bolt, remove the clamp and the intake pipe of the air filter.

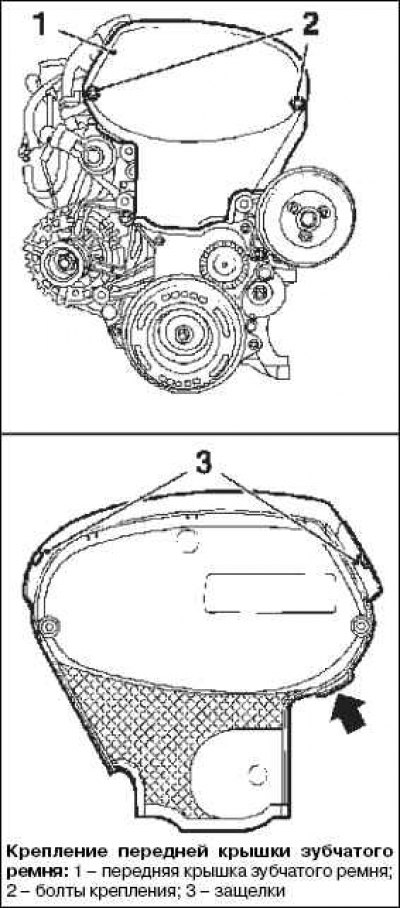

Unscrew the two mounting bolts, disconnect the upper latch and remove the front toothed belt cover (top).

Note. Pull the front cover of the toothed belt up, by the ledge (arrow in the picture).

Remove the ignition module cover in the direction of the arrow shown on it.

Note. Mark the position of the arrow on the cover.

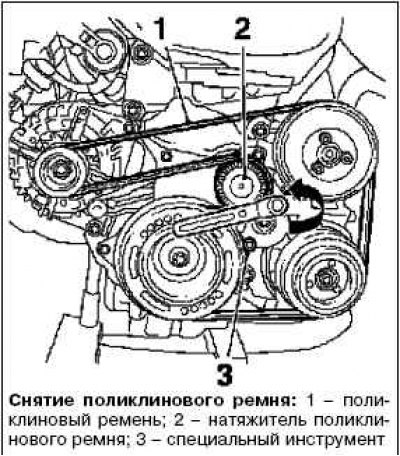

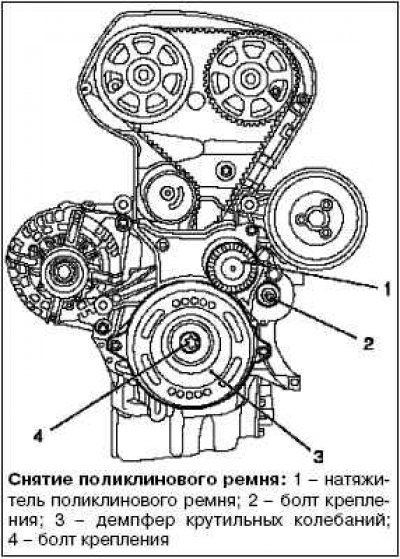

Remove poly V-belt.

Note the direction of rotation.

Compress the V-ribbed belt tensioner in the direction of the arrow in the figure and fix it with the special tool KM 6130.

Remove the oil dipstick guide tube.

Remove the dipstick.

Turn away bolts of fastening.

Remove the engine transport brace.

Raise the vehicle.

Remove the engine mudguard.

Remove the catalytic converter oxygen concentration sensor harness.

Remove the wire ties.

Disconnect the wiring harness connector.

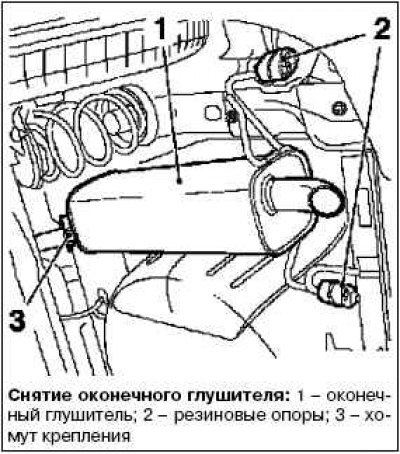

Remove the end silencer.

Loosen the fastening clamp.

Loosen the mounting nut and remove the muffler from the bracket.

Disconnect the 2 rubber mounts and remove the end muffler from the front muffler.

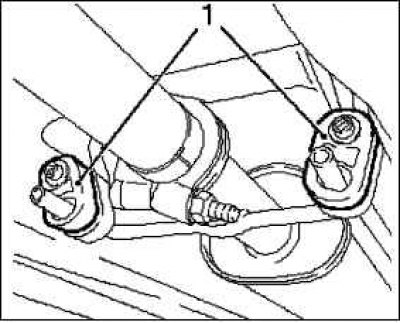

Disconnect the front exhaust (2) from the catalytic converter by unscrewing the 3 fastening nuts.

Remove the front exhaust pipe from the front muffler by unfastening the 2 rubber mounts (1).

Place a container underneath to collect the liquid.

Drain the engine oil.

Disconnect the oil level sensor harness connector.

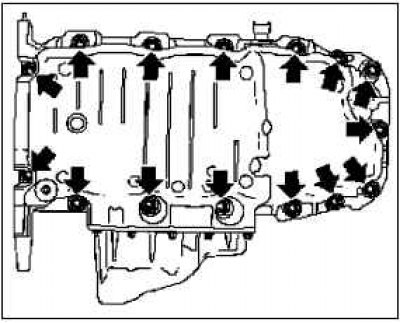

Remove the oil pan.

Remove 2 rubber plugs.

Remove the 3 mounting bolts from the gearbox.

Loosen 15 mounting bolts (arrows).

Disconnect the oil pan with a suitable tool.

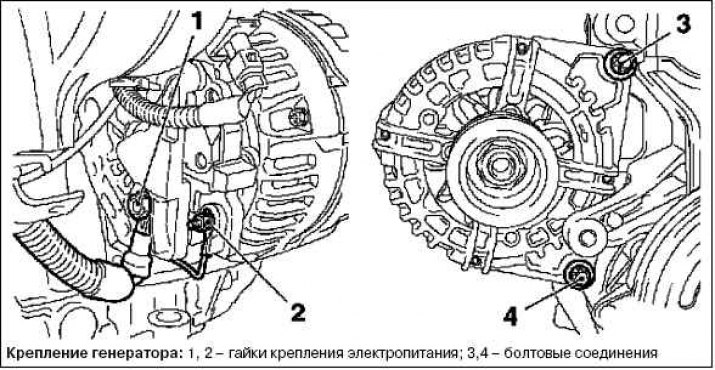

Disconnect the alternator from the power supply by unscrewing the 2 fastening nuts.

Disconnect 2 bolt connections.

Remove the alternator.

Remove the plugs.

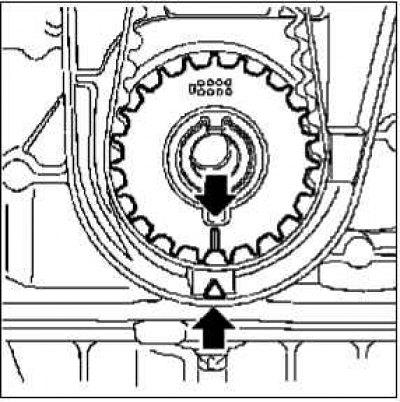

Insert special tool KM 911 and block the flywheel.

Remove the vibration damper by removing the mounting bolt.

Remove the V-ribbed belt tensioner by unscrewing the fastening bolt.

The poly V-belt tensioner is blocked using a special tool KM 6130.

Remove the front toothed belt cover (bottom), by unscrewing the 4 mounting bolts.

Set the engine to TDC.

Remove the KM 911 special tool.

Tighten the vibration damper bolt.

Rotate the crankshaft of the engine in the direction of rotation, set the piston of cylinder No. 1 to the top dead center position (TDC) (arrow).

Insert special tool KM-6173.

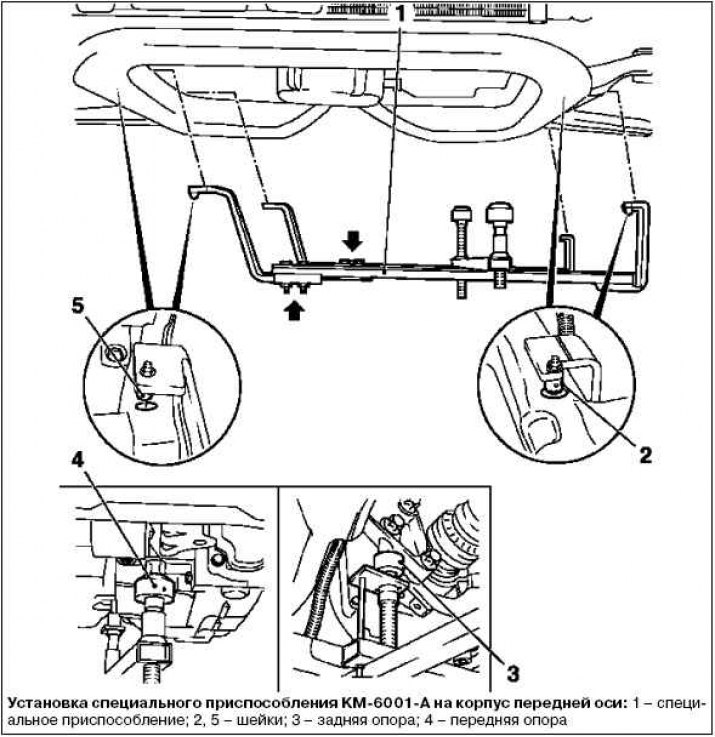

Attach KM-6001-A.

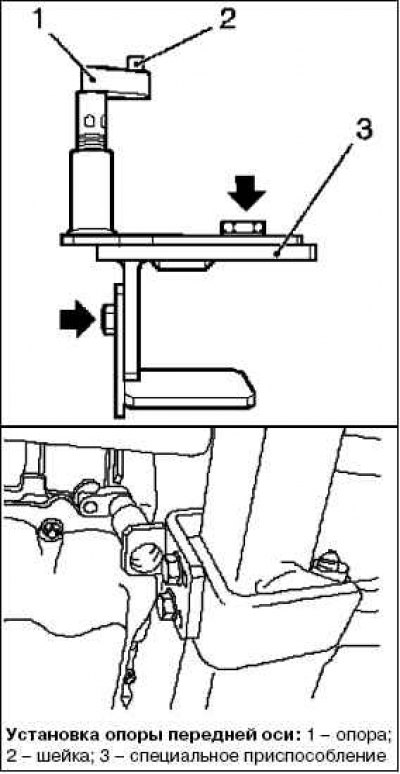

Note. The use of KM-6001-A ensures that the drive is aligned with the front axle housing.

Loosen 3 bolts (arrows) in steering tires.

Insert special tool KM-6001-A.

The journals must be in the holes in the guide of the front axle housing.

Tighten the 3 mounting bolts in the adjusting rails.

Adjust the supports and raise them up to the stops on the guide pins.

Tighten the 3 adjusting pinch bolts.

Adjust the supports - front and rear.

Raise the supports up to the stop on the rail necks.

Note. The necks of the guide should be located on the supports without a gap.

Lower the car

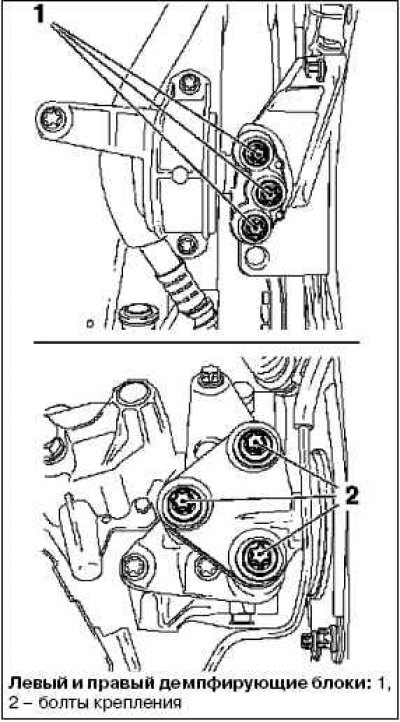

Remove the engine damping block with the right damping block adapter by removing the 6 mounting bolts.

Remove the right support of the engine damping block, unscrew the 3 mounting bolts.

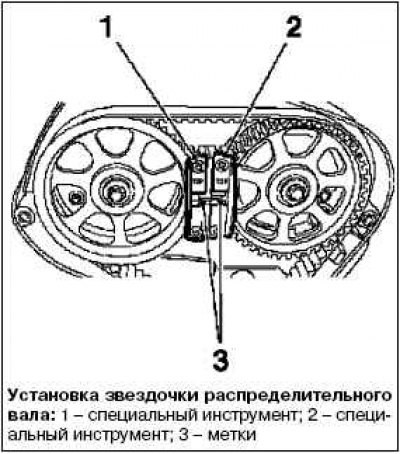

Install the camshaft gears using the special tool KM 6340.

Install the camshaft sprockets so that the marks (3) were located opposite each other.

Install special tool KM-6340-left on the intake camshaft sprocket (I).

Install special tool KM-6340-right.

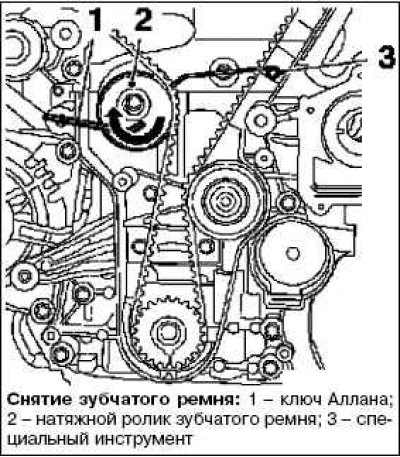

Remove toothed belt, mark direction of rotation.

Apply force to the toothed belt tensioner in the direction of the arrow using the Allan key. Fix with special tool KM 6333.

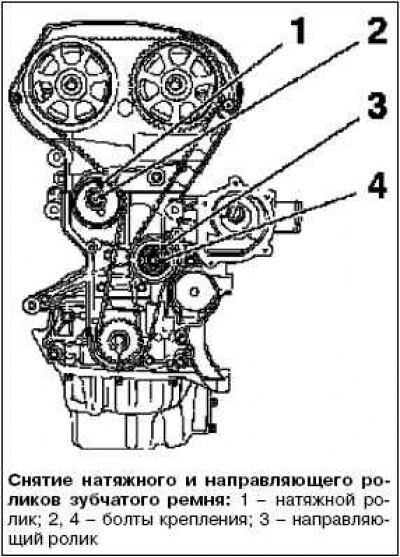

Remove the tension and guide rollers of the toothed belt.

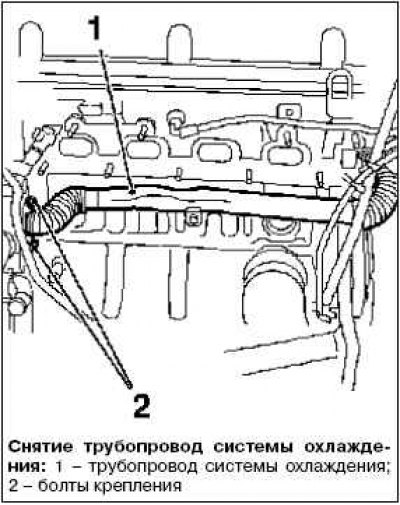

Remove the cooling system piping by unscrewing the 2 mounting bolts.

Remove the pump module by unscrewing the 8 mounting bolts.

Note. The bolts are of different lengths.

Remove the crankshaft seal (front) suitable tool.

Examination

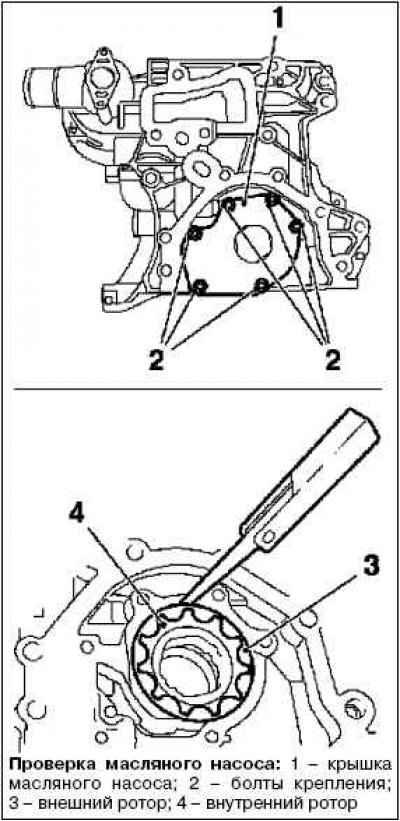

Check the distance between the outer rotor and the pump module.

Remove the oil pump cover.

Check the distance between the outer rotor and the oil pump housing.

Remove the outer rotor with the inner rotor.

Visually check the nodes.

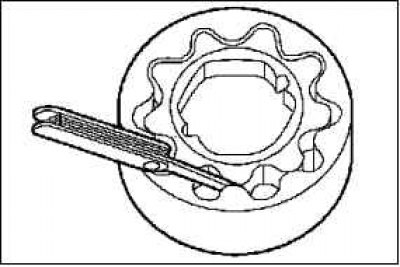

Measure the gap between the inner and outer rotor.

Installation

Install the oil pump cover.

Tighten 6 mounting bolts to 8 Nm.

Install the pump module.

Note. The screws are of different lengths.

Tighten 8 mounting bolts to 20 Nm.

Insert the crankshaft front O-ring.

Clean sealing surfaces.

Apply silicone grease to the sealing lip (white).

Install the protective sleeve on the crankshaft journal.

Fit the O-ring by sliding it along the protective sleeve onto the crankshaft journal.

Press the O-ring into the crankshaft.

Remove the protective sleeve and press the O-ring into the pump crankcase using the KM 6351 special tool.

Use the crankshaft drive gear bolt and washer.

Install the remaining components in the reverse order of removal.

Visitor comments