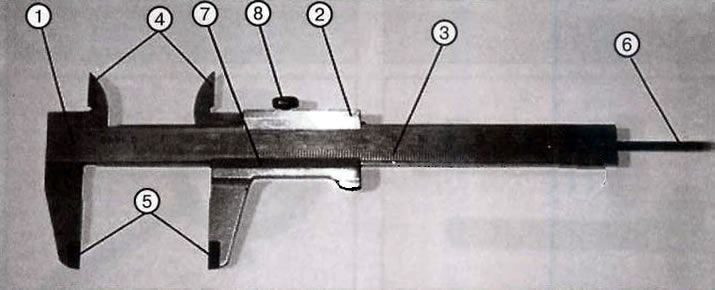

1. Rod.

2. Movable frame.

3. Barbell scale.

4. Sponges for internal measurements.

5. Sponges for external measurements.

6. Depth gauge ruler.

7. Nonius.

8. Frame clamp screw

The caliper is a versatile tool designed for high-precision measurements of external and internal dimensions. In addition, a caliper can determine the depth of holes and protrusions.

The measuring jaws of the caliper can also be used to measure the parallelism of the sides of workpieces.

Calipers have measurement limits of 0-125 mm (ShTs-1), 0-160mm (ShTs-2) and 0-400 mm (ShTs-3).

The most commonly used caliper ShTs-1.

To measure external dimensions and control parallelism, the main measuring jaws of the tool are used, to measure internal dimensions and markup, auxiliary pointed jaws are used.

Using a depth gauge, determine the depth of holes and protrusions.

The caliper device is based on a ruler with divisions (barbell) and an auxiliary scale-nonius, which moves along the main ruler-rod. With the help of this auxiliary scale, you can count the fractions of division of the main scale.

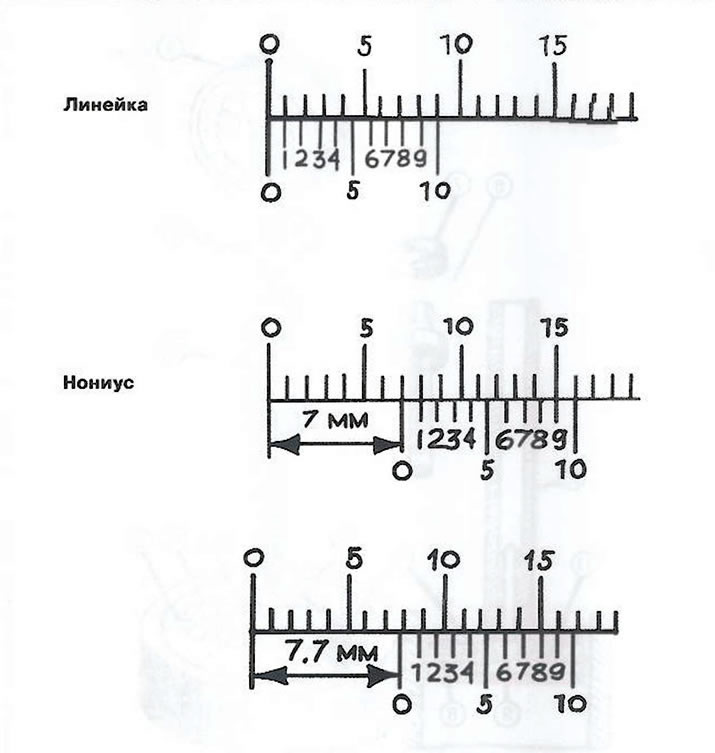

The principle of operation of the vernier is based on the difference between the division intervals of the main scale and the vernier scale. This difference is equal to the division price of the vernier, and the number of divisions depends on the division price.

If the scale division interval is 1 mm, and the vernier division interval is 0.9 mm, then the vernier division value is 0.1 mm.

Thus, if we combine the zero division of the vernier with the zero division of the main scale of the caliper, then the first division of the vernier «fall behind» from the first division of the main scale by the difference between the intervals of the scales, i.e. by 0.1 mm, the second division by 0.2 mm, etc.

The tenth division of the vernier, having shifted by 1 mm, coincides with the ninth division of the main scale of the rod, that is, if the division value of 1 mm is divided by the number of divisions of the vernier (on 10), we get 0.1 mm (see fig.)

Example:

If the zero stroke of the vernier coincides with any stroke on the ruler, then this division indicates the size in whole millimeters.

If the zero stroke of the vernier did not coincide with the stroke on the main scale, then the division on the ruler closest to the left shows an integer number of millimeters, and tenths are counted according to the vernier.

To an integer number of millimeters, as many tenths of a millimeter are added as the number of vernier strokes is counted until any stroke of the vernier coincides with one of the strokes of the ruler. The figure shows an example of reading 7 mm, and 7.7 mm.

In the process of work and at the end of it, it is necessary to wipe the caliper with a cloth soaked in a water-alkaline solution, then dry with a clean cloth. At the end of work, cover the surface of the caliper with a thin layer of any technical oil and put it in a case. Avoid rough impacts or falls during operation in order to avoid bending of the rod and other damage, scratches on the measuring surfaces, friction of the measuring surfaces on the controlled part.

Visitor comments