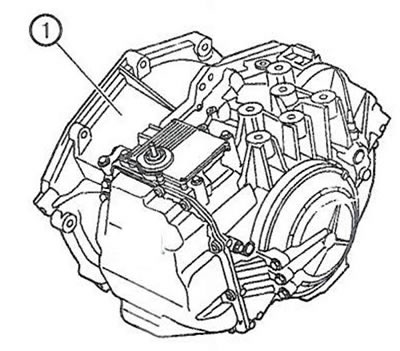

Automatic transmission AF40-6 (1) six-speed electronically controlled with a mode switching lock system. The gearbox is mounted directly behind the engine and has a built-in final drive with differential. power unit (engine with gearbox), located transversely at the front of the vehicle, provides drive to the front wheels of the vehicle. PRND transmission modes are selected using the selector lever located on the center console. It is possible to manually shift gears one up / down.

The gearbox can be divided into three components:

- mechanical components.

- hydraulic components.

- Electronic control system.

Mechanical components include:

- Torque converter with lockup clutch.

- Two planetary gears, each duplicating the other.

- Three disc clutches.

- One band type brake.

- One multi-disc brake.

- One overrunning clutch.

- Main gear with differential.

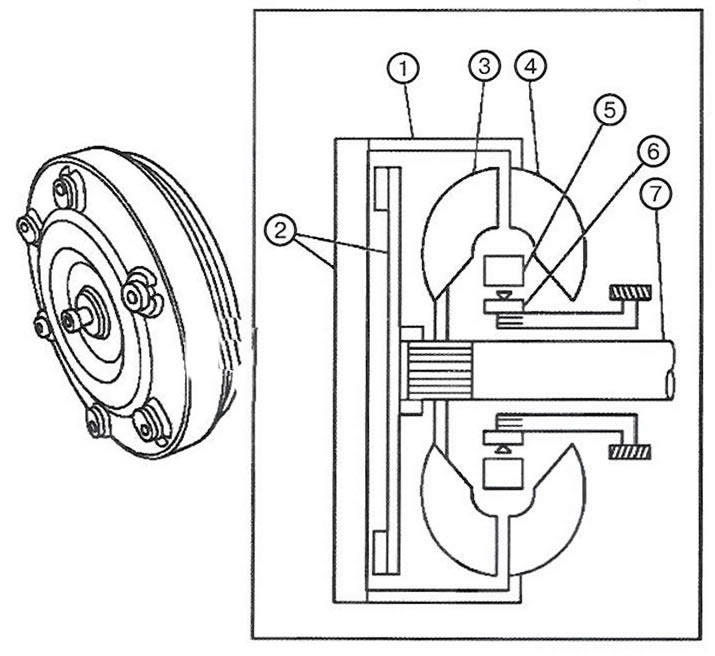

1. Torque converter housing.

2. Torque converter.

3. Turbine.

4. Impeller.

5. Stator.

6. Overrunning clutch.

7. Primary shaft.

The torque converter is bolted to the flywheel (leading flange) engine. The torque converter is filled with oil supplied under pressure by the automatic transmission pump. This unit itself is a hydraulic transmission that smoothly increases the engine torque. The greatest increase in torque occurs at a set engine speed (when the vehicle is stationary and at wide open throttle while driving), and the maximum value of the torque is achieved at a steady frequency of rotation of the gearbox input shaft.

torque converter clutch (blocking) activated at constant speed when there is no need to increase torque. The difference in speed between the engine and gearbox gives an increase in torque even when the vehicle is moving at a constant speed, but entails energy loss in the form of heat, which is reflected in the form of an increase in fuel consumption.

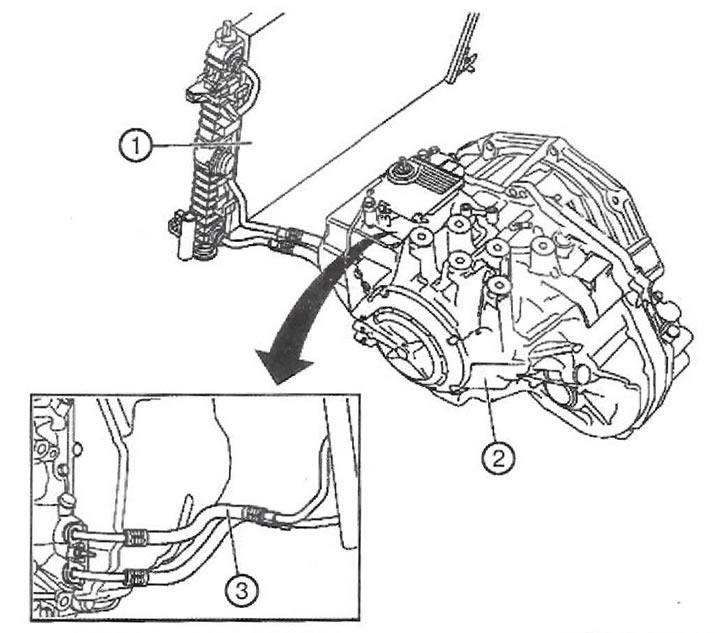

1. Radiator cooling system

2. Gearbox

3. Hydraulic hoses

The automatic transmission is equipped with an oil cooler integrated into the radiator of the engine cooling system. The working fluid circulates through the working pump through the hoses to the radiator and back to the gearbox.

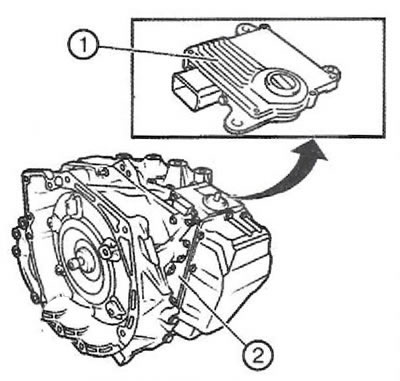

1. Transmission control unit.

2. Gearbox.

The gearbox is electronically controlled. Transmission control unit (TCM - Transmission Control Module) mounted directly on top of the gearbox and has two connectors - one for the vehicle's electrical system and the other for the gearbox. Hall-type gear engaged sensor is integrated into the control unit. The transmission control unit is installed in such a way that the selector lever stem passes through it. The selector lever position sensor is calibrated in position «N» using a diagnostic tool, mechanical adjustments are excluded. The transmission control module controls the shift or shift solenoids. Solenoids are controlled by pulse width modulation to obtain a wider range of fluid flow.

The reverse gear prevention function is activated if the vehicle is moving faster than 7 km/h when the lever is moved from the position «N» V «R».

Among other things, the transmission control unit has an internal fault diagnosis system. Solenoids are checked for an open circuit or short circuit. An analysis of the impulse and inductive voltages allows us to conclude that the windings are partially closed. The speed and temperature sensor circuits are also checked. The high-speed data bus is checked for loss of necessary messages. Mechanical failures (slip or erroneous transmission) are determined by comparing the values from the speed sensors and the occupied gear.

If power to the transmission control unit or solenoids is cut off, the vehicle may continue to move. Regulations «ABOUT» / «M» transmissions will have two gears, a «p» - «R» - «N» - will continue to work in the normal mode, however, gear shifting will be carried out according to an unadjusted (draft) scheme.

In the event of a serious mechanical or electrical failure in the transmission, the transmission control module will stop supplying power to the solenoids in a controlled manner. In most cases, the control unit will try to maintain the set mode of operation of the gearbox until the vehicle stops. Subsequently, the control unit will try to implement two gears in the selected modes «D» / «M» transmission. After that, the power supply to the solenoids will be cut off and the transmission will lose electronic control.

If an invalid or erroneous gear ratio is detected, the engine torque will be limited to 170 Nm and 150 Nm respectively in reverse and forward gears.

If other faults occur, the torque will also be limited to higher values depending on the fault.

Visitor comments