Removing

Loosen the wheels, raise the front of the car.

Mark the wheels and hubs with chalk so that you can then install the wheels in their original position. Remove wheels.

Knock out the fixing pins on the outside with a special punch.

Be careful not to pop out the springs.

Attention: If the brake pads are to be used again, they must be marked before removal. It is unacceptable to interchange the pads of the inner and outer sides, just like the pads of the left and right wheels. The change can lead to uneven braking. Only original pads from OPEL must be used. Change the pads on both wheels together.

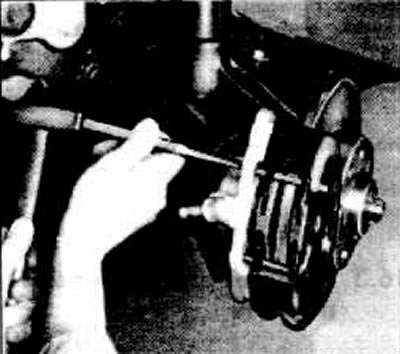

Pull the outer pad out of the brake caliper with a collet.

Then pull out the inner block. If the pad comes out with difficulty, you need to insert a screwdriver into the eye of the pad and knock it out with light blows.

Installation

Clean the guide surfaces, in particular the caliper shaft, with a soft metal brush or cloth. Do not use products containing mineral oil or sharp-edged tools. Check whether the dust boot and clamping ring fit well in the brake caliper.

Damaged, cracked and hardened anthers should be replaced.

Before installing the brake pads, check the brake disc. It is necessary to feel it with your fingers, if there are grooves, then the disk is necessary. Remove and grind or replace with a new one.

Measure the thickness of the disk. In workshops, a special meter is used for this, because. due to wear, an edge forms on the disc.

The thickness of the disk can be measured with a conventional caliper, if a gasket of known thickness is placed on each side and then subtracted from the measurement results. The total thickness of the pads.

If grooves are found in the brake disc, it should be machined. In this case, one should not forget about the minimum thickness of the disk.

If the wear limit of the brake disc is reached, it must be replaced.

Attention: Both brake discs must be either regrooved or replaced.

| Engine | Brake disc thickness in mm | ||

| New | After processing | wear limit | |

| 1.0-/1.2-/1.3-l | 10 | 9 | 8 |

| 1.6-l | 12,7 | 11,7 | 10,7 |

| 1.8-l | 20 | 19 | 18 |

Press back the piston in the brake cylinder. In workshops, a device for returning the piston back is used for this purpose. You can also press back the piston with a smooth piece of wood. To do this, a brake shoe is installed on one side so that the brake disc does not warp. Be careful not to damage the boot.

Attention: If the piston is pressed back, the brake fluid is removed from the brake cylinder into the compensation reservoir. Keep an eye on the fluid in the reservoir. It is possible to suck out the brake fluid with a siphon.

Caution: Brake fluid is poisonous and will damage paintwork. Never suck out brake fluid by mouth through a hose.

For ATE brake caliper with floating caliper. Rotate the piston setting 20°. In workshops, a 20°template is used for this.

Install template.

The long side of the template should be in contact with the brake caliper. The piston has a ledge, this ledge must be in contact with the inclined surface of the template, otherwise turn the piston.

Piston setting is correct when the bottom part of the template is adjacent to the caliper shaft, and with its 20°slope coincides with the piston projections.

If necessary, turn the piston with special pliers or a hard wood pin.

Attention: As a rule, when replacing pads, the piston does not change position.

Insert brake pads. When installing, pay attention to the fact that the block can easily move back and forth.

Insert the pins from the outside so that the holes (white arrows) were facing each other.

Install spring clips (black arrows), as it shown on the picture.

Install the front wheel, the chalk marks should match.

Lower the vehicle, tighten the wheel bolts crosswise to 90 Nm.

Important. Depress the brake pedal several times until the brake pads are in place.

Check the brake fluid level in the reservoir, top up if necessary.

Attention: With new brake pads the first 200 km. It is necessary to brake carefully, if possible, avoid sudden braking.

Visitor comments