Removing

Attention: With a high mileage of the car, the old drive shaft should be replaced as a set. Right drive shaft (looking in the direction of travel) 346mm longer than the left.

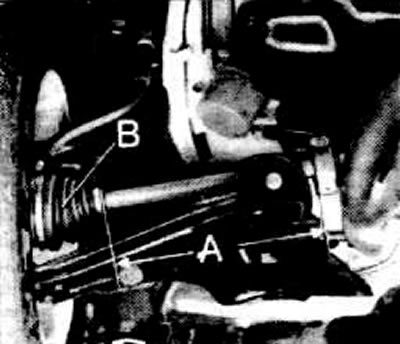

On the right (long) drive shaft acting two-part mass (vehicles with engines from 1.6 liters and gearbox). When unscrewing, maintain a distance A = 260 mm from the fastening of the outer hinge cover (IN).

Loosen the slotted nut on the drive shaft.

Put the supports under the bottom, engage the gear, put on the handbrake.

Loosen castle nut.

Caution: The vehicle must be supported while doing this, otherwise there is a risk of an accident.

Loosen the wheel nuts, raise the car.

Loosen the ball joint, unscrew the nut. Press out the ball joint with a special puller. See fig. A8288 Section 12.1.

Attention: Since October 1982, driven shafts have been used, which, unlike the previous shafts, do not have a shear stop in the internal joint. If the joint moves further than intended, the inner part of the joint may fall out of its outer part, and the drive shaft will lose its function as a result.

Attention: For all work in which the drive shaft will be removed from the gearbox housing, it must be ensured that you can only pull on the hinge, and not on the shaft. When removing and installing the drive shaft in the front wheel hub, do not forget this when working with the inner joint.

Drive the drive shaft out of the gearbox housing. In specialized workshops, a special device and a hammer weighing 1500 g are used for this.

Attention: The grips of the tool always point towards the gearbox.

Gearbox F10 (1.2-/1.3-l engines). Knock out the drive shaft on the left side of the crankcase using the KM-460-2 or KM-460-1 tool. The grips of the tool must face the gearbox.

Gearbox F16 (1.6-/1.8-l engines). Drive shaft on the left side, knock out the KM-503 tool from the crankcase, on the right side, press the drive shaft out of the crankcase using a pry bar.

Attention: From November 1983 modified drive oxen are installed. On these shafts, there are 3 thickenings in the longitudinal direction on the splines of the inner hinge. When removing the shaft, you need to pull on the hinge, and in no case on the shaft.

When removing the drive shaft, oil flows out. Be sure to close the drive shaft hole tightly with a plug (ET-No. 9092869).

If there is no special tool at hand, the drive shaft should be knocked out with a flat chisel. In this case, you must first remove the differential cover.

Attention: Oil will start to flow out.

Insert a flat chisel between the end of the shaft and the shaft of the bevel gear and press out the shaft.

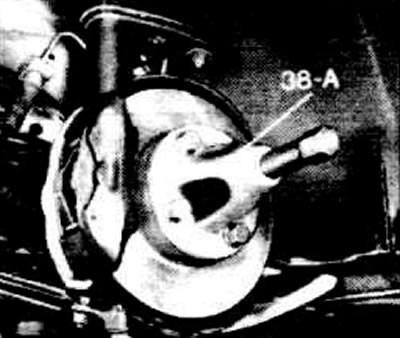

Pull the drive shaft out of the wheel hub by hand. If this is not possible, then squeeze it out with a special puller.

Installation

Attention: Handle the new shaft with care. The shaft must not lie on the hinge covers for a long time.

All mating surfaces of the outer joint, as well as the surface of the hub bearing, must be absolutely clean.

Lubricate the shaft teeth with gear oil.

Insert the drive shaft into the hub.

Screw on a new castle nut with a new washer.

Lubricate the junction of the drive shaft with the gearbox housing with gear oil.

Install a new retaining ring.

Attention: Do not overtighten the retaining ring.

Press the drive shaft into the gearbox housing by hand. Then press the retaining ring with a screwdriver until it catches.

Insert the screwdriver into the boss, not into the casing.

After inserting the retaining ring into the groove, check the tightness of the installation.

If the differential cover was removed, attach the cover with a new gasket. Glue the new gasket to the cover with grease. Fasten with 30 Nm bolts.

Fit ball joint, tighten castle nut to 75 Nm.

Attention: If the cotter pin does not fit, tighten the nut longer until the position and the hole for the cotter pin match. Pin the ball joint.

Screw on the wheel, lower the car.

Secure the drive shaft with a new castle nut with a new washer to 100 Nm.

Loosen the nut and tighten again with 20 Nm.

Place a torque wrench on the slotted nut and mark the tires with 90°marks with chalk. To do this, starting from the key, make marks with chalk after 1/4 turn.

Attention: If the cotter pin cannot be inserted, the nut should be loosened and not tightened until the position and the cotter pin hole match.

Pin the nut.

Tighten the wheel bolts crosswise to 90 Nm.

Fill with transmission oil.

Visitor comments