Specialized workshops use the KM-128 control device to check the belt tension. If such a device is not available, then the belt tension cannot be accurately checked and set, because. The new V-belt has a high preload. If the device is not at hand, the tension can be checked by pressing with a finger where the device is applied. The deflection should be approximately 15 mm. In any case, the tension of the V-belt should be checked during the next workshop maintenance, as If the tension is incorrect, the belt may slip.

Examination

To check the tension, if possible, the middle between the two pulleys is selected.

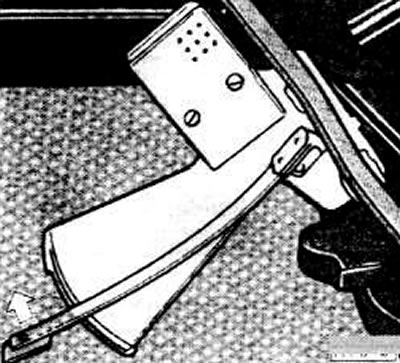

Place the control device on the belt so that it hangs on it.

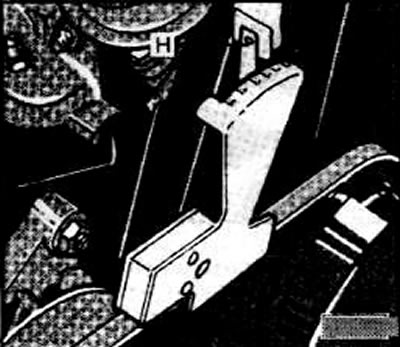

Press the lever -H- until the point -D- of the device touches the belt.

When the belt is touched, a buzzer will sound.

Take readings from the school of the device and multiply by 100. This value corresponds to the belt tension in newtons (H).

The tension should be 250-300 N, in no case should it be less than 250 N.

Attention: The tension of the new belt is 450 N.

If the tension is below the standard, tension the belt.

Tension

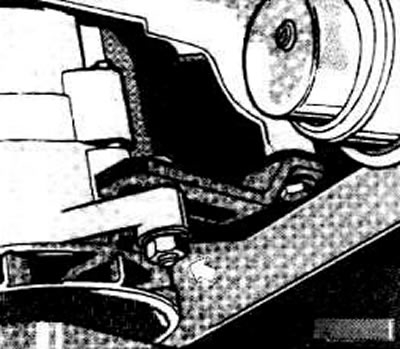

Loosen the tension plate, press the generator with a pry bar, tighten the tension plate.

Check belt tension, repeat installation if necessary.

Visitor comments