Checking and adjusting the engine idle

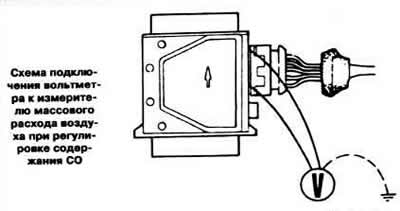

Carbon monoxide regulation (SO) in the exhaust gases can be carried out as described for the system «Motronic ML4.1», or by doing the following:

- make sure the ignition is off;

- connect a digital voltmeter to the leads «2» And «6» (see picture) mass air flow meter pads without disconnecting the connector;

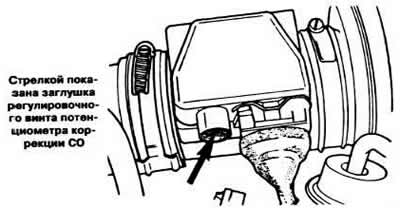

- connect the gas analyzer according to the operating instructions, start the engine at idle and check the CO content, which should be within 0.7-1.2%. If it differs from the norm, remove the plug of the adjusting screw (shown by the arrow in the figure) CO correction potentiometer and turn the screw until a voltage of 0.9-1.4 V is obtained according to the voltmeter;

- press the accelerator pedal several times and leave the engine to idle: the level of CO content in the exhaust gases should be set within the required limits;

- after adjustment, install a new plug on the adjusting screw of the CO correction potentiometer.

Fuel pressure check

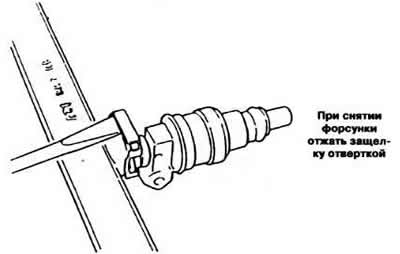

Slowly unscrew the fitting that secures the fuel supply line to the fuel line to gradually release the pressure.

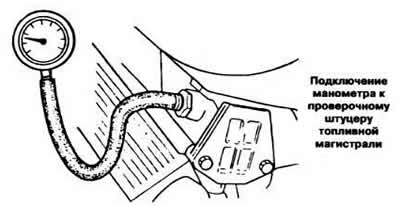

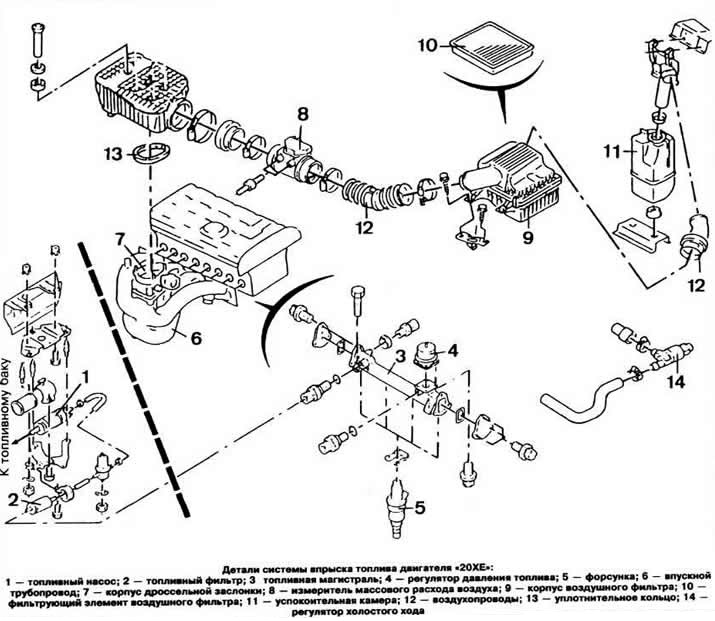

Connect a pressure gauge to the test fitting of the fuel line (see picture).

Disconnect the vacuum hose from the pressure regulator.

Start the engine at idle.

Measure the fuel pressure in the system using the pressure gauge, which should be in the range of 2.3-2.7 kg / cm2.

Connect the vacuum hose to the pressure regulator, after which the fuel pressure should decrease by 0.3-0.5 kg / cm2.

Switch off the ignition, disconnect the pressure gauge.

Connect a pressure gauge through a tee to the fuel drain hose and disconnect the vacuum hose from the pressure regulator. In this case, the pressure gauge should show a pressure of 0.3-0.5 kg / cm2. Throttle Position Sensor Adjustment

Remove the protective cover from the throttle body.

Loosen the clamp of the mass air flow meter, unscrew the five screws securing the meter and remove the meter.

Disconnect the wire harness connector.

Remove the two mounting clamps and unscrew the two nuts on the bracket.

Loosen the two Phillips screws and turn the throttle position sensor housing counterclockwise to adjust the clearance, then rotate the sensor housing clockwise until resistance is felt. Tighten the two Phillips screws securing the sensor housing.

To check the operation of the sensor, open the throttle a little; at the same time, a click of the switch operation should be heard.

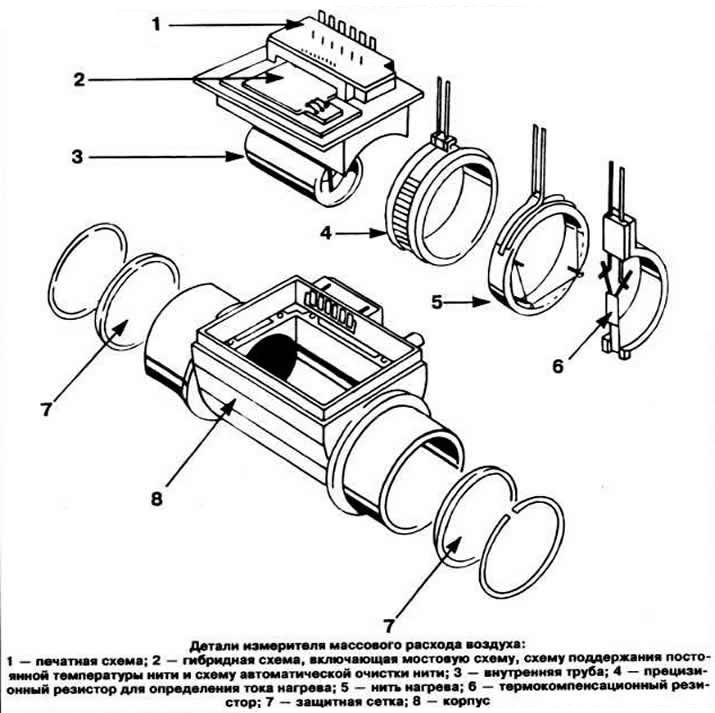

Checking the Mass Air Flow Meter

Disconnect the meter connector and connect an ohmmeter to the terminals in «1» And «2» pads and measure the resistance, which should be zero.

Connect an ohmmeter to the leads «2» And «3» meter pads. Resistance on an ohmmeter should be in the range of 2.5-3.1 ohms.

Disconnect the clamp that secures the air duct to the meter.

Remove the meter holder.

Start the engine and let it run for 10 seconds at about 1000 rpm.

Switch off the ignition, remove the air duct and check the condition of the filament of the meter, which should be bright red for about 1.5 s 4 s after the engine is stopped.

CO correction potentiometer check

Slide the insulating boot off the mass air flow meter connector.

Connect a digital voltmeter to the leads «2» And «6» pads.

Start the engine at idle. The voltage on the voltmeter should be in the range of 0.9-1.4 V.

Switch off the ignition. Attach to Pins «2» And «6» ohmmeter meter pads.

Remove the potentiometer adjusting screw cap.

Mark the position of the potentiometer adjusting screw and turn it fully counterclockwise. Resistance on an ohmmeter should be in the range of 0-30 ohms.

Turn the potentiometer screw fully clockwise. Resistance on an ohmmeter should be in the range of 900-1100 ohms.

Turn the potentiometer adjusting screw to the previously marked position.

Note. In no case do not violate the factory throttle setting. Before removing the idle speed control, mark the air hoses so that they can be reattached to their original positions during installation.

Visitor comments