Install the satellites into the differential box using the KM 160 4 conductor, after putting the thrust washers in place.

Install side gears with thrust washers by turning them in the differential case.

Put the pinion axle in place and fix it with the locking bolt.

Heat the new speedometer drive gear to a temperature of 80°C and install it on the differential box as follows. so that the protrusions of the gear go into the grooves of the differential box. To facilitate the installation of the gear, use the KM 525 tool.

Lubricate the teeth of the speedometer drive gear with bearing grease.

Heat the differential driven gear to a temperature of 80°C, controlling the heating temperature with a thermochromic pencil. press it onto the differential box and secure with new bolts.

Using KM 522, press on the differential case the inner races of the tapered roller bearings.

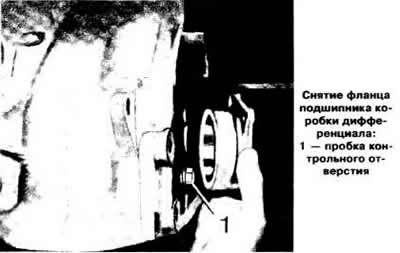

Press the outer rings into the adjusting nut and flange

Install new O-rings on the flange and adjusting nut. Install the differential case bearing flange and tighten its mounting bolts.

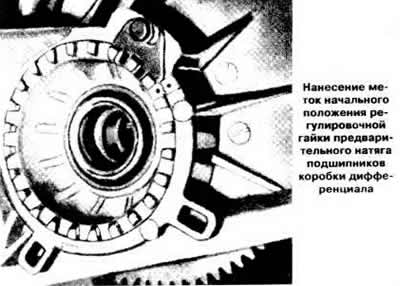

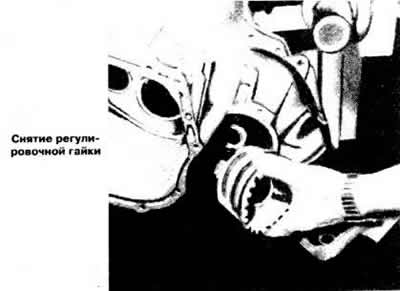

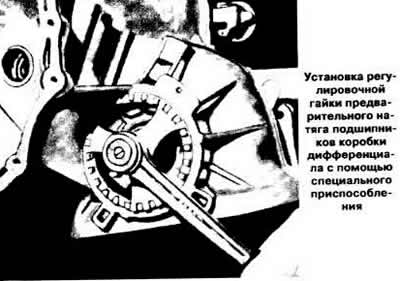

Apply protective lubricant to the threads of the adjusting nut. Tighten the adjusting nut with KM 520 tool.

When reusing the parts, tighten the adjusting nut to align the marks made during disassembly and obtain a moment of resistance to turning the bearings within 6-10 kgf·m. For new bearings, the turning resistance moment should be in the range of 17-19 kgf·m at a rotation speed of 1 rev / s. After installing the gearbox housing and differential, provide a moment of resistance to turning the bearings within 17-19 kgf·m for new and 8 kgf·m for used bearings.

Lock the adjusting nut by bending the tabs on the lock plate.

Install the plug in the adjusting nut and in the gearbox housing.

Apply bearing grease to the differential cover gasket, grease it to the cover, install the differential cover and secure it with new bolts.

Note. In differential gearbox type «F20» the axis of the satellites is locked with a pin, and not with a bolt, as in the differential of the gearbox type «F16». Thrust washers of semi-axial gears are installed with a bearing surface of a larger diameter towards the gear. To center the side gears, a KM 524 A mandrel is used.

Visitor comments