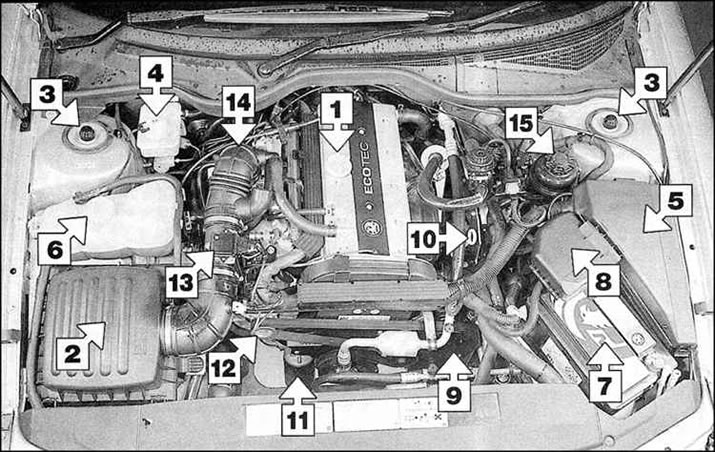

1. Engine oil filler cap

2. Air filter housing

3. Upper front suspension strut mount

4. Brake fluid reservoir

5. Relay box

6. Expansion tank

7. Battery

8. Block of burnable jumpers

9. Power steering pump

10. Engine oil dipstick

11. Oil filter

12. Generator

13. Air flow sensor

14. Throttle cover

15. Power steering reservoir

View of the engine compartment of models with a 2.5-liter engine (3.0L engine is similar)

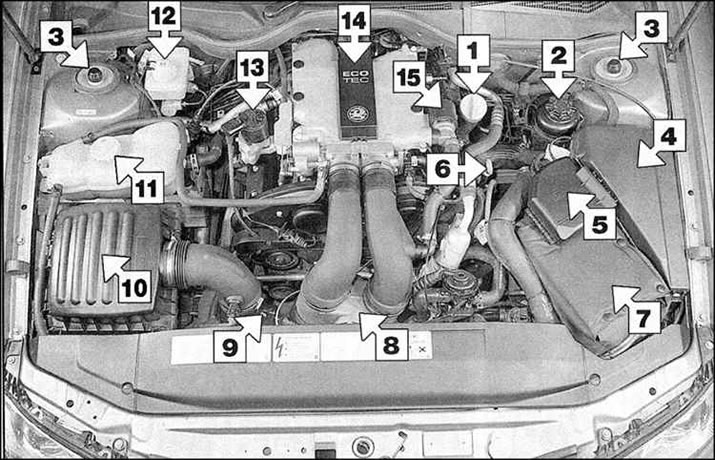

1. Engine oil filler cap

2. Power steering reservoir

3. Upper front suspension strut mount

4. Relay box

5. Block of burnable jumpers

6. Engine oil dipstick

7. Battery

8. Air chamber

9. Air flow sensor

10. Air filter

11. Expansion tank of the cooling system

12. Brake fluid reservoir

13. Exhaust gas recirculation valve

14. Intake manifold

15. Idle speed control valve

Bottom view of the engine bay for 2.0L DOHC models (other models are similar)

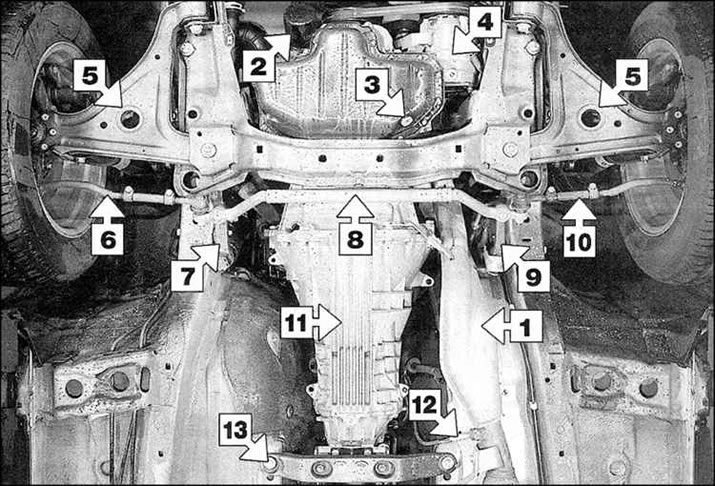

1. Exhaust pipe

2. Oil filter

3. Engine oil drain plug

4. Air conditioner compressor

5. Lower suspension arm

6. Outer tie rod

7. Bipod

8. Central tie rod

9. Bipod

10. Outer tie rod

11. Manual transmission

12. Oxygen sensor

13. Transmission mounting crossbar

In this manual, the term "Maintenance" refers to the totality of work performed, and not to a specific procedure.

If, from the moment you purchase a new car, you strictly follow the maintenance procedure, carry out frequent checks of the level of fluids and parts subject to increased wear, as strongly recalled in the Manual, then the engine will maintain high performance and the amount of additional work will be minimized.

However, if maintenance is not carried out regularly, engine performance is likely to be unsatisfactory. This is especially true of the engine of a car that was not purchased new, which was not subjected to regular checks. In such cases, in addition to periodic maintenance, additional adjustment work must be carried out.

Any kind of maintenance work or search for the cause of abnormal engine operation should begin with a compression test in the cylinders. Cylinder compression testing provides valuable information regarding the general condition of many engine internals that can be used as a basis for both routine maintenance and repair procedures. If, for example, the compression is such that severe engine wear is evident, then routine maintenance will not restore normal performance and all work will be reduced to an unnecessary waste of time and money.

Below is a list of work, the implementation of which often leads to the restoration of normal operation of the engine.

Primary checks:

- clean, inspect and test the battery;

- check the oil and coolant levels;

- check the condition and tension of the drive belt;

- replace spark plugs;

- check the air filter and replace it if necessary;

- check the fuel filter;

- check the condition of all hoses and inspect them for leaks.

If the above operations were not effective, perform secondary checks - all the operations listed above, plus:

- check the battery charging system;

- check the ignition system;

- check the power system.

Visitor comments