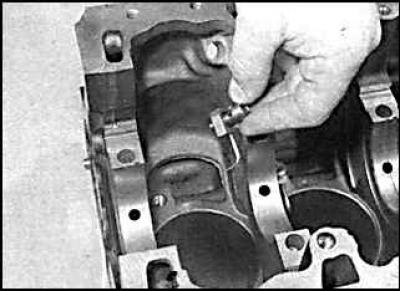

2. Remove the oil sprayers on the inside of the pistons. They are bolted on.

3. Remove all traces of gaskets from the mating surfaces of the engine block.

4. Remove all oil line plugs. When installing, use new plugs.

5. Clean the most polluted places with steam.

6. Clean all lubrication holes and oil line. Rinse all internal channels with a stream of warm water until the water comes out clean. It is necessary to completely dry the cylinder block and lubricate all mating surfaces with a thin layer of oil to prevent corrosion. Also lubricate the engine cylinders. If compressed air is available, use it to speed up the drying process and blow out all oil holes and lines.

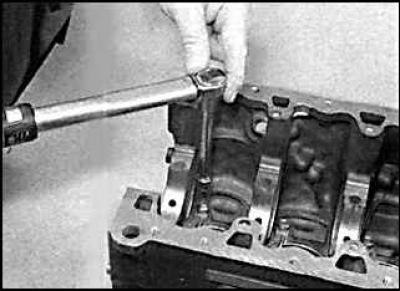

7. Thoroughly clean all threaded holes using a properly threaded tap, then blow out the holes with compressed air.

8. Install plugs in the oil line in the engine block and fasten them securely.

9. Install oil sprayers.

10. If the engine cannot be reassembled immediately, cover the cylinder block with a large plastic bag to protect it from contamination.

11. Visually inspect the cylinder block for corrosion. Check the integrity of the threads in the threaded holes.

12. Check the diameter of the engine cylinders for wear by the presence of a step at the top of the cylinder.

13. If you have a measuring tool, measure the liner diameter of each cylinder at the top (under the wear step) in the center and at the base parallel to the axis of the crankshaft. Then make the same measurements perpendicular to the axis of the crankshaft and compare them with the technical data. Repeat the measurement procedure on the remaining cylinder liners. If the wear exceeds the allowable values, it is necessary to bore the cylinders and install new oversized pistons. Oversized pistons (0.5 mm) available for all engines.

Visitor comments