2.0 liter engines

1. Remove the oil pump and flywheel.

2. Remove pistons and connecting rods.

3. Check the free play of the crankshaft.

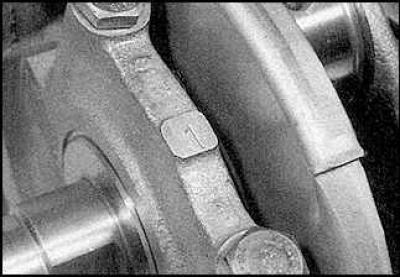

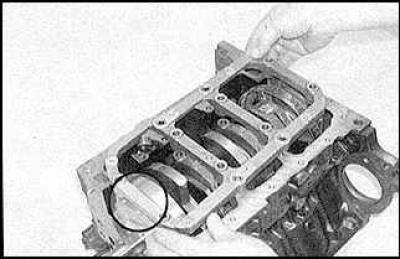

4. The main bearing caps must be numbered 1 to 5. If the caps are not numbered, number them. Cover N1 is located on the side of the timing belt.

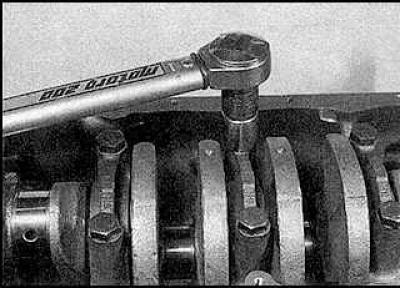

5. Unscrew the bolts of the covers, remove the covers together with the bearing shells.

6. Remove the crankshaft.

7. Remove loose leaves from the block of cylinders and remove half rings of the central bearing.

2.5 and 3.0 liter engines

8. Remove the oil pump and flywheel.

9. Remove pistons and connecting rods.

10. Check the free play of the crankshaft.

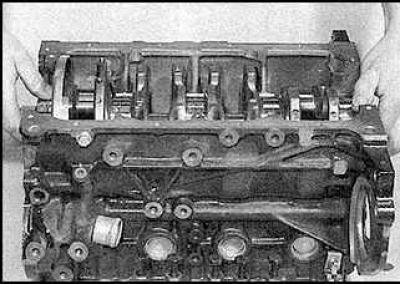

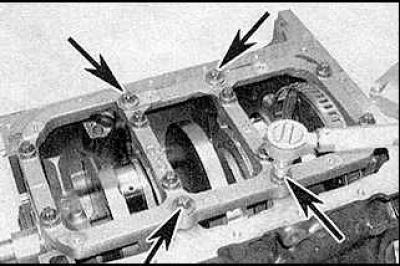

11. Remove the four cover block bolts securing the block to the cylinder block.

12. Unscrew the remaining eight bolts of the cover block, remove the bolts and remove the block.

13. The main bearing caps must be numbered 1 to 3. The N1 cap is located on the side of the timing belt. If the covers are not numbered, number them.

14. Remove the covers together with the bearing shells.

15. Remove the crankshaft.

16. Remove loose leaves from the block of cylinders and remove half rings of the central bearing.

Shaft free play check

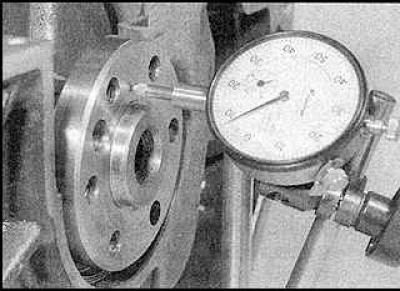

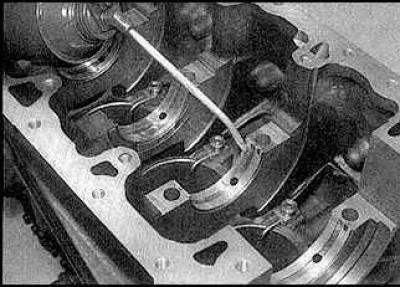

To carry out the test, the crankshaft must be installed in the cylinder block.

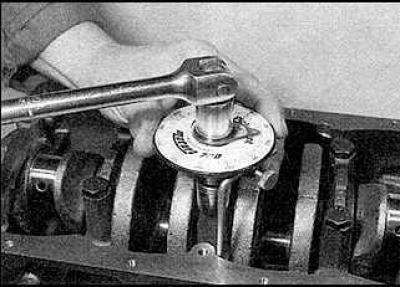

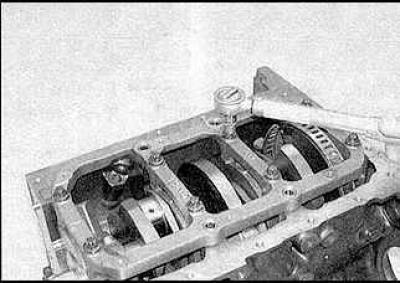

Check the free play of the shaft using a special measuring tool (drawing on the left) or with measuring probes (drawing on the right).

Examination

1. Clean the crankshaft with solvent and dry it with compressed air.

2. Inspect the crankshaft bearing journals for signs of wear, scratches, corrosion, or cracks. Rub a copper coin on the bearing. If the bearing wears off the copper, then its surface is too rough and needs to be machined.

3. Inspect the crankshaft for cracks or other damage.

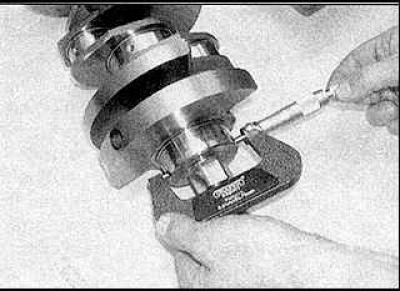

4. Measure the diameters of the main and connecting rod bearings. Check the bearing journals for taper and ovality.

5. Check the crankshaft seal journals for signs of wear or damage. If the seals have worn out the grooves on the journals, then the new seals will leak oil.

6. Measure the shaft runout.

7. If wear, damage or any non-compliance with specifications is found, contact a specialist.

Insert selection

For the correct selection of liners, be guided by the size of the lubrication gap, which can be measured using a plastic measuring tape. If you have any problems with the selection of liners, contact the specialists.

Checking the lubrication clearance of the main bearings

1. Thoroughly clean the back surfaces of the earbuds.

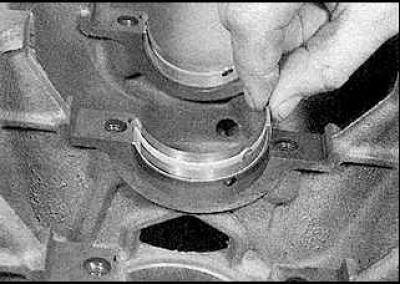

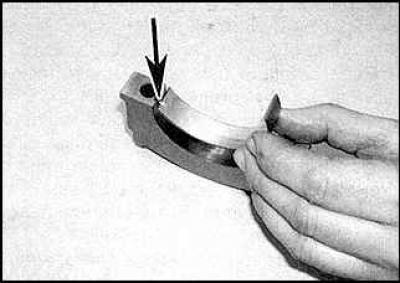

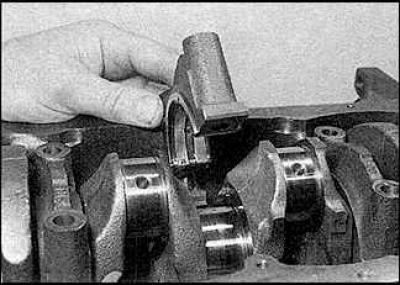

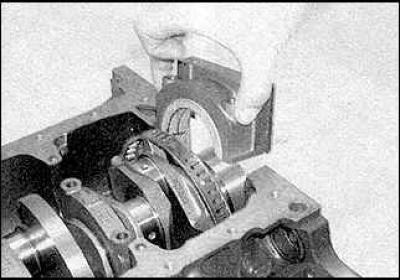

2. Install the earbuds by aligning their tabs (indicated by an arrow) with recesses in the covers and cylinder block.

3. An internal micrometer or other special device can be used to measure the lubrication gap, but the most accurate and easiest method is to use a special plastic gauge.

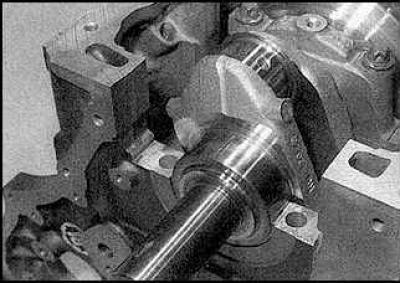

4. Clean the crankshaft, bearings and oil holes, then carefully install the crankshaft onto the bearings.

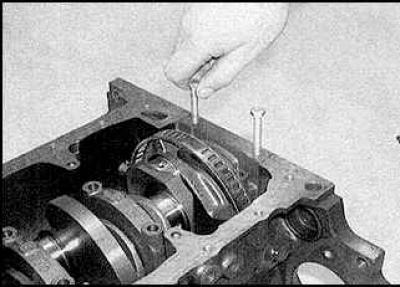

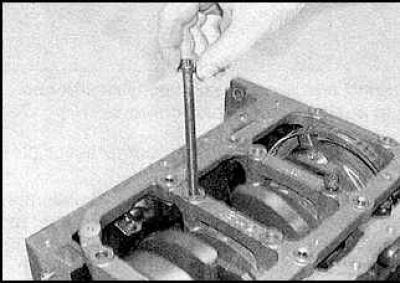

5. Lay a piece of plastic on each of the main bearings along the axis of the shaft.

6. Install the main bearing caps being careful not to move the plastic. Tighten the fixing bolts of the covers to the required tightening torque. Do not turn the crankshaft.

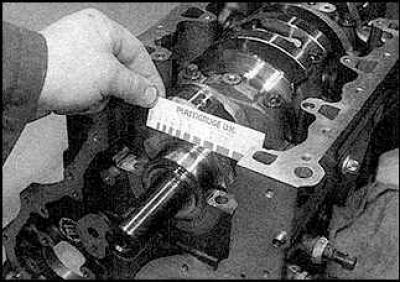

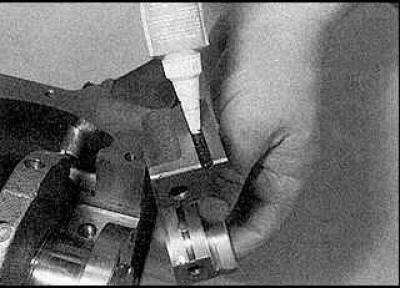

7. Loosen the screws and carefully remove the covers.

8. Measure the width of the crushed film using the lubrication gap scale.

9. If the clearance is not within specifications, install a different size of bearings.

10. Carefully remove traces of film from the shaft and bearings.

Final installation of the crankshaft

2.0 liter engines

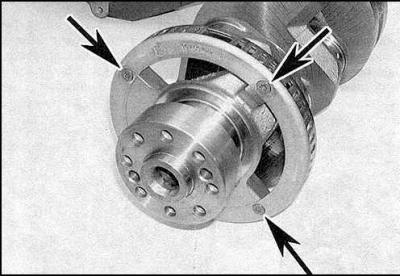

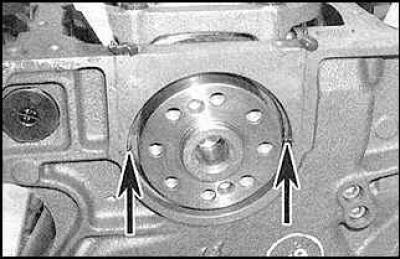

1. Carefully remove the crankshaft. If you are installing a new shaft, be sure to reposition the shaft sensor rotor (mounting bolts are indicated by arrows).

2. Install bearing shells. Earbuds with side protrusions (A) mounted on a central bearing (N3) in engines of 2.0 liters and on the rear bearing (N4) in engines of 2.5 and 3.0 liters. The rest of the earbuds have no protrusions (IN).

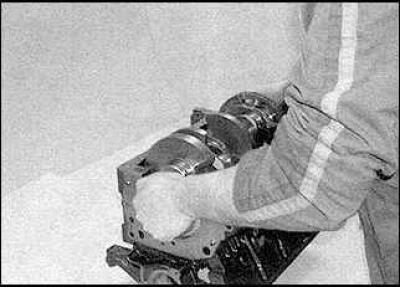

3. Clean the surface of the top bearings and lubricate them with grease or engine oil. Check that the crankshaft bearings are clean and reinstall the crankshaft.

4. Lubricate and install the lower bushings. Install the main bearing caps.

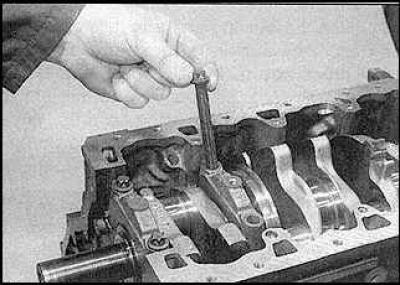

5. Clean the rear cover and fill the side grooves of the cover with sealant N15 03 295. Install the rear cover.

6. Lubricate the cap bolts with engine oil, insert the bolts and tighten them by hand.

7. Tighten all main bearing cap bolts to the correct torque.

8. Tighten the bolts to the required angle.

9. Turn the crankshaft by hand several times and check for ease of movement.

2.5 and 3.0 liter engines

10. Install the crankshaft.

11. Install the shells in the bearing caps and install the caps 1-3 in the cylinder block.

12. Clean the rear cover and fill the side slots in the cover with sealant N15 03 295.

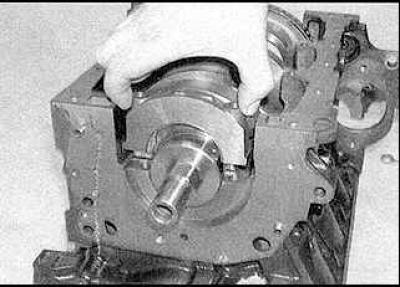

13. Install the back cover.

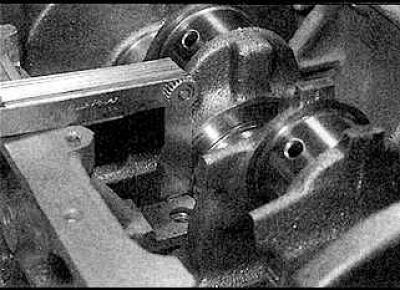

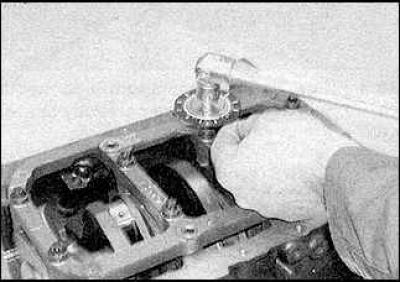

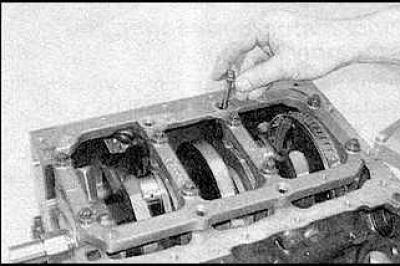

14. Install the cover block so that the arrow on the block points towards the timing belt.

15. Lubricate the threads of the new cover block bolts and install the bolts.

16. Tighten the bolts to the required tightening torque.

17. Tighten the bolts to the required angle.

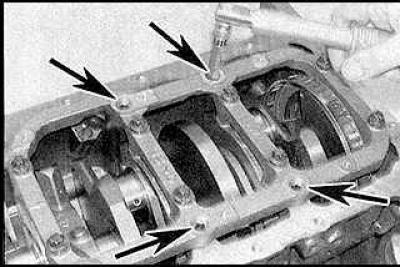

18. After you have tightened the bolts, squeeze some more sealant into the grooves of the back cover (indicated by arrows). The sealant should flow from the joints.

19. Turn the crankshaft by hand several times and check for ease of movement.

20. Screw sleeves into the cover block (indicated by arrows) with threads cut into them and tighten them to the required tightening torque.

21. Insert the bolts securing the cover block to the cylinder block.

22. Tighten the bolts (indicated by arrows) to the required tightening torque.

Visitor comments