Removing

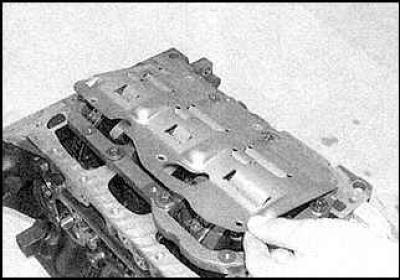

1. On 2.0 liter SOHC engines, remove the cylinder head and oil pan. Remove the oil pickup tube and baffle plate.

2. For 2.0 liter engines, remove the cylinder head, oil pan and oil pickup pipe. On models manufactured after 1998, remove the crankshaft balance block. On earlier models, remove the sump divider.

3. On 2.5 and 3.09 liter engines, remove the cylinder heads and oil pan. Remove the partition wall.

4. Remove ledges at the top of the cylinders resulting from wear.

5. If the connecting rods and connecting rod caps are not marked, mark them. On 2.0 liter engines, the N1 cylinder is located on the timing belt side. On 2.5 and 3.0 liter engines, the N1 cylinder is located on the right side of the cylinder block on the timing belt side.

6. Set piston N1 to bottom dead center.

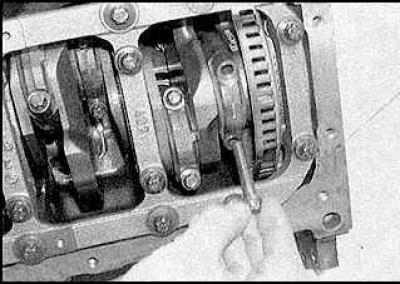

7. Remove the bearing cap bolts for the first connecting rod. Remove the connecting rod cap and lower bearing shell, mark the shell.

8. Remove the bearing shell and remove the connecting rod from the top of the cylinder block.

9. Remove the rest of the connecting rods and pistons in the same way.

Examination

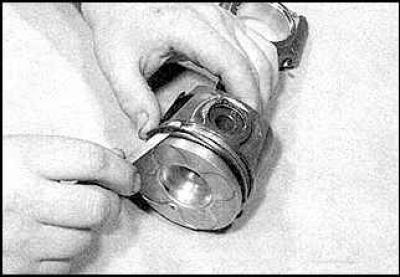

1. Remove old piston rings. Clean the piston head from deposits and clean the grooves for the piston rings. After removing all deposits, clean the pistons and connecting rods with solvent and dry them.

2. If the pistons and cylinder walls are not very worn and the cylinders have not been bored, new pistons do not need to be installed.

3. Carefully inspect all pistons for cracks in the piston skirt and around the connecting rod pin.

4. Inspect pistons for scratches, nicks, burnt areas, or corrosion.

5. Measure the piston diameters and compare the results with the specifications.

6. Measure the clearance between piston and cylinder. To do this, it is necessary to subtract the piston diameter from the cylinder diameter or insert the piston into the cylinder and measure the gap with a feeler gauge. If the clearance is too large, the piston must be replaced.

7. Do the same for the rest of the pistons.

8. Inspect the connecting rods for cracks or other damage. For a more detailed verification of pistons and connecting rods, contact the specialists.

9. On 2.0 and 2.5 liter engines, the piston pin is fixed in the connecting rod bearing, so have a professional replace the piston or connecting rod.

10. On 3.0 liter engines, use a small screwdriver to remove the piston pin circlips and remove the pin.

11. Inspect the pin for wear and damage, if damage is found, replace the pin and connecting rod.

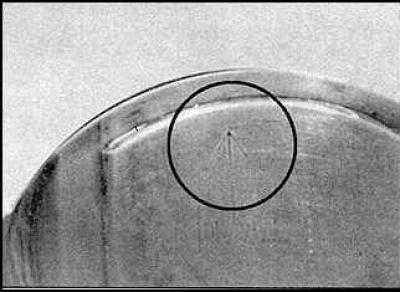

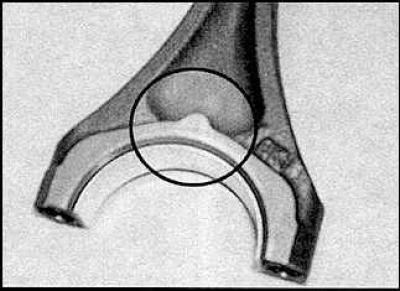

12. Lubricate the piston pins and assemble the pistons and connecting rods so that the arrows on the piston heads (drawing on the left) and marks in the bases of the connecting rods (drawing on the right) were directed in opposite directions.

Installing and checking the lubrication clearance of connecting rod bearings

Insert selection

For the correct selection of liners, be guided by the size of the lubrication gap, which can be measured using a plastic measuring tape. If you have any problems with the selection of liners, contact the specialists.

Checking the lubrication clearance of connecting rod bearings

An internal micrometer or other special device can be used to measure the lubrication gap, but the most accurate and easiest method is to use a special plastic gauge.

1. Temporarily install the piston in the cylinder, install the liners, tighten the connecting rod cap bolts, and check the connecting rod bearing lubrication clearance in the same way as checking the main bearing lubrication clearance.

2. If the clearance is not correct, the wrong size bushings may have been installed.

Final installation of pistons and connecting rods

1. Remove all traces of plastic. Check that the surface of the bearings is absolutely clean and lubricate them with engine oil.

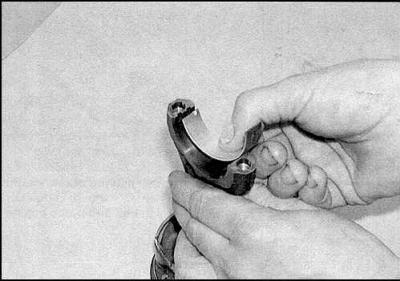

2. Clean the upper connecting rod bearing and install it on the connecting rod. The lubrication holes of the connecting rod and bushing must be aligned.

3. Clean the second bearing and install it in the connecting rod cap.

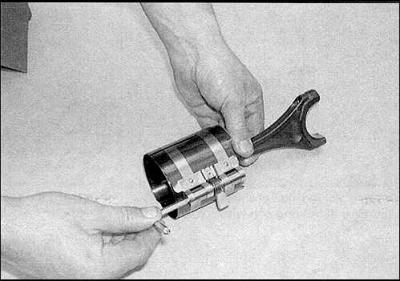

4. Lubricate the pistons and rings and compress the piston rings with the special tool.

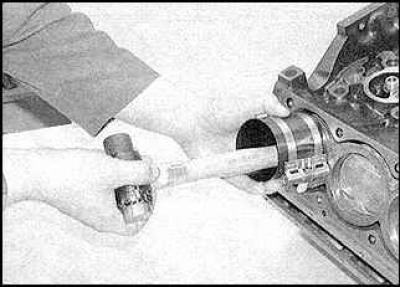

5. Rotate the crankshaft so that the #1 cylinder connecting rod bearing is at bottom dead center and lubricate the cylinder walls.

6. Check that the arrow on the piston head points towards the timing belt.

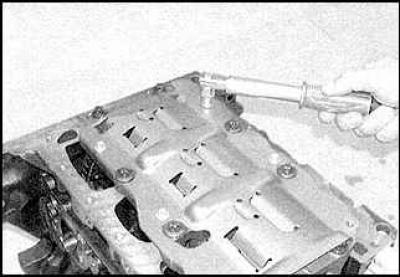

7. Press down on the piston and install it into the cylinder.

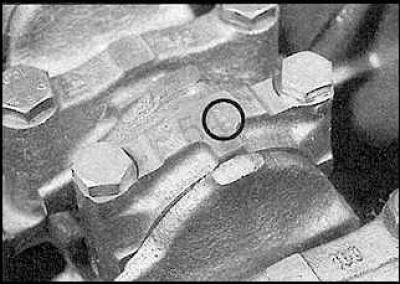

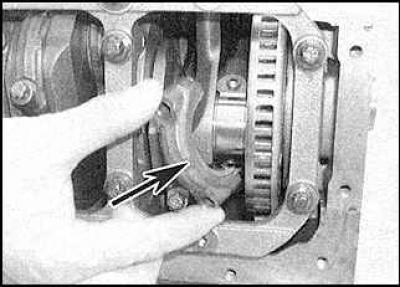

8. Install the connecting rod on the shaft journal, install the connecting rod cap so that the protrusion (indicated by an arrow) on the cover was directed towards the flywheel.

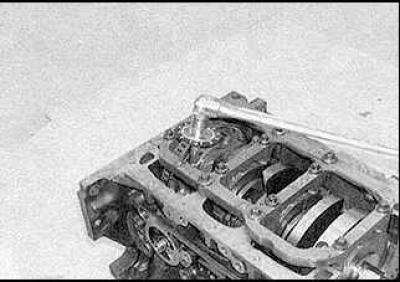

9. Insert the cover fixing bolts.

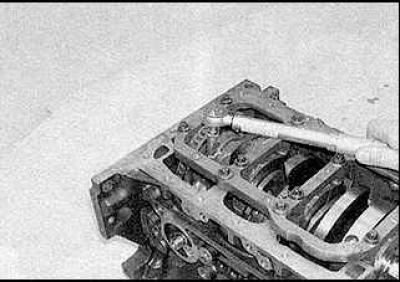

10. Tighten the bolts to the required tightening torque.

11. Tighten the bolts to the required angle.

12. Install the rest of the pistons in the same way.

13. After installing all the connecting rods, rotate the crankshaft several times and check for ease of movement.

14. Install the remaining parts depending on the engine model.

Visitor comments