Removing

1. Remove the gearbox.

2. Mark the installation position of the pressure plate on the flywheel.

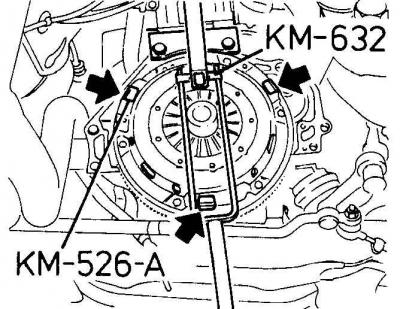

3. In a diagonal order, gradually unscrew the fixing bolts and remove the pressure and friction disc. In order not to damage the diaphragm spring, it is recommended to use a special tool (the arrows indicate the location of the pressure plate mounting clips).

Inspection

1. Inspect the friction surface for wear, loose rivets, or contamination. Inspect the pressure plate for deformation, cracks, broken diaphragm spring plates and worn splines. Replace disk if necessary.

2. Inspect the surfaces of the flywheel and pressure plate. If they are badly scratched or have grooves or cracks, replace them.

3. Check the condition of the release bearing.

Installation

1. Wipe pressure plate and flywheel.

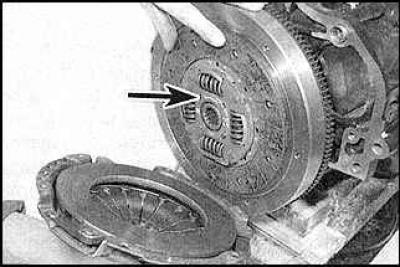

2. Install the friction disc on the flywheel with the springs facing out.

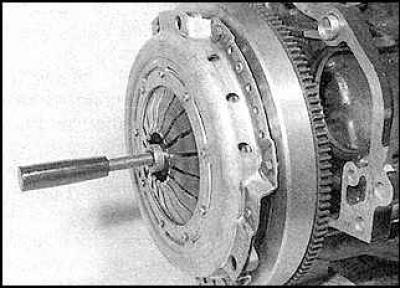

3. Install the pressure plate and install the mounting bolts.

4. Position the friction disc exactly in the center of the flywheel and housing and gradually tighten the mounting bolts in a diagonal pattern to the required torque.

Visitor comments