Attention! Tires and rims of certain sizes must not be used with snow chains.

When replacing a disk, one should take into account not only its width and diameter, but also the pressing depth. The pressing depth is the distance from the middle of the disc to the contact surface of the wheel disc to the brake disc.

All disc wheels are made with an annular ledge. The annular protrusion is a bead pressed onto the landing shelf, which, even with a very sharp turn of the car, does not allow the disc to squeeze the tubeless tire.

Tread Height Measurement

According to existing legislation, it is allowed to use tires with a residual pattern height of at least 1.6 mm along the entire tread tread.

For safety reasons, it is recommended to replace summer tires already at a residual tread height of 2 mm, and winter tires at 4 mm.

The tread height should be measured at the points of greatest wear. At the bottom of the longitudinal grooves of the tread there are marks of tire wear (TWI). The locations of the marks are marked on the sidewall of the tire with the letters TWI or triangles.

Tire pressure - check

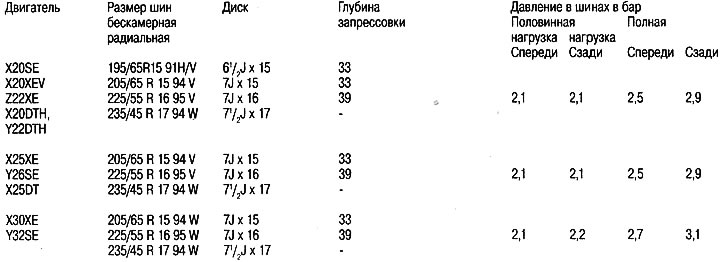

The tire pressure is set by the vehicle manufacturer depending on various parameters. These include the vehicle load and the maximum permitted speed.

It is important to maintain the correct pressure in the correct size tires. Compliance with the prescribed tire pressure is of great importance for driving safety, as well as for the life of the tyres. For this reason, it is recommended to check the tire pressure at least once every two weeks and before every long trip (including the spare wheel).

1. Check pressure only when tires are cold. Excessive tire pressure resulting from a long journey must not be relieved. The tire pressure increases by about 0.2-0.4 bar during continuous driving.

Winter tires are usually operated with excess pressure, i.e. about 0.2 bar higher than in summer. The values recommended by the winter tire manufacturer must be observed. If winter tires have a speed limit, the corresponding maximum speed must be indicated on a sticker that must be within the driver's field of vision. When driving with a trailer, the tire pressure must be brought to the values indicated in the column «Full load».

The prescribed tire pressure can be found in the owner's manual for the vehicle.

When checking tire pressure as part of maintenance, check the pressure on the spare wheel as well. The air pressure in the spare tire must correspond to the maximum vehicle load.

Required tools:

- pump or compressor (at a gas station).

2. Unscrew the protective cap of the tire valve.

3. Check and bring the pressure in the tires to the prescribed values.

Tire valve check

4. Unscrew the protective cap of the tire valve.

5. Lubricate the opening of the valve with soapy water or spit it. If a bubble forms, tighten the spool with the other end of the protective cap.

6. Check valve again. If bubbles continue to form and the valve no longer tightens, replace it. Entrust the work to the workshop.

7. Screw the protective cap onto the valve.

Anti-skid chains

Snow chains may only be fitted on drive wheels.

Driving speed with snow chains must not exceed 50 km/h. On roads without snow drifts and ice, the chains must be removed.

It is recommended to use only chains with small links, no more than 15 mm, including the connecting link.

Changing/Changing Wheels

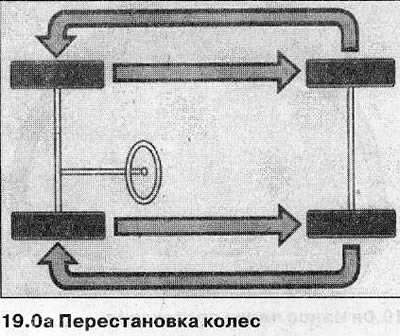

It is not advisable to change the direction of rotation of the tires when rearranging the wheels, because Tires are only run in to the new direction of rotation after heavy wear. On some tire models, the direction of travel is indicated by an arrow on the sidewall of the tire. In these cases, the indicated direction of movement must be strictly observed.

With noticeably greater wear on the front wheels, it is recommended to swap them with the rear ones. This ensures approximately equal service life of all 4 wheels.

Attention! Change tires not separately, but at least the tires of both wheels of the same axle. In this case, tires with a larger residual tread depth must always be installed in front, on the front wheels. All 4 wheels should only be fitted with tires of the same type and, if possible, with the same type of tread pattern and from the same manufacturer. Tires that are more than 6 years old should only be installed if absolutely necessary and be extremely careful when driving, never use used tires whose origin is unknown. When replacing wheels and tires, be sure to change the valve as well.

Removing the wheel

1. Mark with paint or chalk the position of the wheel on the hub if the wheel is to be reinstalled. Thanks to the marks, the balanced wheel can be set to its original position (see illustration).

Wheels made of light metal alloy are coated with a layer of protective varnish. Be careful not to damage this layer when removing or installing the wheel. If necessary, paint over the damaged area with an appropriate varnish.

2. Clean dirty wheel bolts. Replace the bolts with new ones if their threads are damaged or rusty. Do not grease wheel bolts.

3. Tighten the wheel bolts in a criss-cross pattern in several passes. The bolt tightening torque for all types of rims is 110 Nm.

Attention! Bolts tightened with different forces or one-sidedly can cause jamming of the wheel on the hub or the hub itself.

Wheel balancing

Serially produced wheels are balanced at the factory. Balancing is necessary to even out different weight distributions and material inaccuracies. In the process of movement, unbalanced wheels manifest themselves through shocks and shaking. Steering wheel shakes at high speed.

As a rule, this jitter occurs only in a certain speed range and stops when the speed increases or decreases.

Over time, wheel imbalance can lead to suspension, steering, and shock absorber failures.

It is necessary to balance the wheels after each tire repair, because due to tire wear and repair, the weight distribution of the tire material changes.

Attention! Balancing the front wheels without removing them from the vehicle is not possible due to the hydraulic support mounted on the transverse suspension arm.

Some tips for caring for tires

Tires have a peculiar «memory», and mishandling them, and this includes, for example, quick or frequent crossings over curbstones or rails, often results in their failure. And this happens only some time later and at the most inopportune moment.

Tire cleaning

Do not wash tires with a steam jet. If the nozzle of this device is held too close to the tire, then its rubber layer is irreversibly destroyed within a few seconds, which cannot be repaired even by applying cold water. Tires cleaned in this way must be replaced for safety reasons.

Tires that have been in contact with oil or grease for a long time must also be replaced. In this case, the tire first swells, and then returns to its normal shape and looks intact on the outside, but the tire's load-bearing capacity is reduced.

Tire storage

Tires should be stored in a cool, dark and dry place. They must not come into contact with lubricants, oils or fuels.

Store wheels lying flat or suspended from rims in a garage or basement. If tires are not mounted on rims, they must be stored in a standing position.

Increase tire pressure slightly before removing wheels (by about 0.3-0.5 bar). For winter tires, use your own rims, since remounting tires for summer rims does not justify itself in terms of economy.

Tire break-in

The new tires have a particularly smooth surface. This is due to the manufacturing process. For this reason, new tires, including a new spare wheel, must be run in. During the running-in process, as a result of the onset of abrasion, the smooth surface becomes rough.

Before driving the first 300 km with new tires, the driver must be especially careful when driving on wet roads.

Tires and wheels - designations

Example of designation on disc wheels 61/2J x 14 ET3Z

6½ is the width of the disc in inches.

J - letter indicating the height and contour of the side (B - low board).

x - the designation of a solid disk.

14 - landing diameter in inches.

ETZZ - pressing depth 33 mm.

195 - tire profile width in mm.

/70 - height to width ratio (the height of the tire profile is 70% of the width).

If there is no special profile height designation, (e.g. 155 R 13), then this means that in this case the usual or «normal» ratio. For radial tires, it is 82%.

R - radial tire.

14 - landing diameter in inches.

89 is a number indicating the allowable load on the tire.

Attention! If there is M + s between the designations 14 and 89, then we are talking about a tire with a winter tread pattern.

H - the letter indicating the maximum permitted speed for these tires (in this case up to 210 km/h).

The letter indicating the maximum permitted speed for these tires is placed after the tire size. The designation of the maximum permitted speed applies to both summer and winter tires (see illustration 19.06).

Letter designations of the maximum permitted speed for tires

Letter designation, Maximum permissible speed

Q - 160 km / h

S - 180 km / h

T - 190 km / h

H - 210 km / h

V - 240 km / h

W - 270 km / h

Date of tire manufacture

The date of manufacture is stamped on the tire as a manufacturer's code.

Example: DOT CUL2 UM8 0703 TUBELESS

DOT - Department of Transport (US Department of Transportation).

CU is the abbreviation for the tire manufacturer.

L2 - tire size.

UM8 - tire construction.

0703 - release date, 7th working week 2003

Note: If instead of a 4-digit number code only a 3-digit number followed by a symbol is shown (, this means that the tire was produced in the past decade. For example, designation 509 (stands for Production Week 50, 1999.

TUBELESS - tubeless tire (TUBETYPE - tube tire)

Attention! Starting from 10/98, new tires must additionally have a control number.

EEC (Economic Commission for Europe) UN, which is applied to the sidewall of the tire. This number confirms that the tire complies with the ECE standard. If after 10/98 tires without an EEC control number are installed, then the vehicle operating permit will be cancelled.

Incorrect tire wear

For front wheels, slightly more wear on the shoulder of the tread than wear on the middle of the tread is normal.

Moreover, due to the slope of the road, the wear of the tread shoulder facing the middle of the road (for the left wheel - the outer shoulder, for the right - the inner), may be more pronounced.

Uneven tire wear is mostly the result of too low or too high tire pressure, but can also be caused by incorrect wheel alignment, poor wheel balance, and defective shock absorbers and discs.

Sawtooth tread wear is usually due to vehicle overload.

Incorrect wheel alignment and wheel imbalance give typical tire wear patterns, which are listed in the list of faults.

Visitor comments