Car wash

Environmental protection laws prohibit car washing in non-designated locations. If the car is often washed in automatic car washes, the rotating brushes of the sink leave marks on the varnish. This can be avoided by washing the car by hand at an appropriate car wash.

Bird droppings, dead insects, tree resin, traces of tar, salt and other aggressive deposits must be washed off immediately, as they contain substances that corrode the varnish coating.

Use plenty of water for washing. Avoid hitting the car with a strong jet of water at a sharp angle. This will damage the lacquer. Wash the car with a soft sponge or glove, starting from the roof and moving from top to bottom, applying light pressure. Squeeze out the sponge frequently.

Use detergents only to remove hardened dirt. After that, rinse off the remaining detergent with plenty of clean water. Regular use of detergent requires more frequent maintenance. You can add a preservative to your car wash water.

Do not direct the jet of water at the inlet vents.

Use a suede cloth to wipe dry. Use different types of suede to wipe lacquer and glass, because preservative residues on the glass lead to a deterioration in its transparency.

Traces of salt used on roads in winter are especially dangerous for all folds and folds, flanges and joints of doors and hoods. Therefore, such places must be thoroughly cleaned with a sponge at each car wash, including even after an automatic car wash, and then rinsed with water and wiped dry with a dry chamois cloth.

Never wash or dry your vehicle in the sun. In this case, water spots are inevitably formed.

Attention! After washing the vehicle, dry the brake discs by light braking while driving.

Lacquer care

Conservation

Cleanly washed and wiped dry lacquer should be coated with a preservative at such intervals and as often as to ensure that the surface is protected from the weather by a water-repellent and pore-closing wax composition.

Any fuel, oil, grease or brake fluid that has come into contact with the paint must be removed immediately, otherwise the paint will discolour.

Preservation of the paint surface must be repeated if, when washing the car, it is clearly visible that the water flows from the paint coating not in the form of droplets, but in a continuous mass. Regular use of a preservative helps preserve the original lacquer finish.

Another possibility to preserve the varnish is the use of wax compositions used in washing. However, they only provide good protection when used at every car wash, provided that the time interval between two washes does not exceed 2-3 weeks.

Polishing Polishing is necessary only when the lacquer coating has lost its original luster due to insufficient care or exposure to dust, industrial emissions, sun and rain, and even the use of preservatives does not ensure its restoration. Do not use polishing agents with high abrasiveness or polishing agents with increased chemical aggressiveness for this, even if the first attempt at such polishing was successful.

Before each polishing, the vehicle must be washed clean and thoroughly dried. In the future, you must follow the manufacturer's instructions for using the polishing agent.

Do not treat a large area at once to avoid premature drying of the polish. Most polishes require the application of a preservative after use. Do not polish in direct sunlight!

Plastic and matt lacquered parts must not be treated with polishes and preservatives, as this usually leads to staining. Removal of tar/tar stains. Resin-containing substances in a short time eat into the paintwork and cannot be completely removed. Fresh stains can be removed with a cloth soaked in washing gasoline.

If necessary, petrol, kerosene or turpentine oil can also be used. A lacquer preservative also works very well against such stains. When using it, you can refuse the subsequent washing.

Insect removal

Insects contain aggressive substances that damage the lacquer coating. Therefore, the affected areas must be washed immediately with warm soapy water or a detergent solution, because insects that have hardened on the surface are difficult to remove by ordinary spraying. There are also special means for removing insects.

Care of plastic parts

Clean plastic parts, leatherette seats, headlining, black matt parts only with water and shampoo. Do not soak the upholstery of the ceiling through. Plastic parts can be cleaned with a suitable plastic cleaner. Do not use solvents such as nitro thinner, cold cleaners, or benzine.

Glass cleaning

Wipe the glass outside and inside with a clean soft cloth. In case of severe pollution, alcohol or ammonia and warm water or a special glass cleaner will help. Move the wiper arms forward when cleaning the windshield.

When cleaning the windshield, also clean the wiper blades.

Attention! When using products containing silicone, brushes, sponges, rags and towels used to clean the lacquer coating should not be used to clean glass. When spraying paints containing silicone, the windows must be covered with thick paper or other material.

Caring for rubber seals

Seal surfaces and surfaces of rubber gaskets from time to time dust with talcum powder or spray with silicone compound. Thus, it will be possible to avoid creaking when closing the doors. Rubbing said surfaces with liquid soap also reduces noise.

Tire cleaning

Do not wash tires with a jet of water from a washer. If the washer nozzle is brought too close to the surface of the tire, its inner rubber layer is irreversibly destroyed within a few seconds, especially when cold water is used. For safety reasons, tires washed in this way should be replaced.

Light alloy rims should be brushed and treated with a suitable product, especially in winter, but do not use aggressive, acidic, highly alkaline, abrasive cleaners or a washing machine with a water temperature above +60°C.

Clean seat belts only with a mild soapy solution without removing them. Do not use chemical cleaners as they destroy tissue. Wind up automatic belts only after they are completely dry. Do not dry the seat belts at temperatures above +80°C or in the sun. Underbody protection and cavity preservation

The bottom of the car, including the wheel arches, is covered with a protective PVC layer. Particularly endangered areas of the front end in the vicinity of the wheel space are protected by a plastic coating against stone impacts. In addition, parts of the body that are at risk of corrosion are made of galvanized sheets, and the tailgate is made of plastic Before the onset of the cold season and after each washing of the bottom, check the condition of the protective layer of the bottom and, if necessary, eliminate its defects.

Dust, clay and sand can accumulate in some areas of the bottom. Remove accumulated dirt, which in winter may also contain salt.

Washing and preservation of the engine

To prevent corrosion on car front parts (e.g. on side members, cross beams), as well as the power unit, the engine compartment, including all parts and assemblies located in the engine compartment, must be covered with a high-quality preservative. This should be done first after washing the car.

Attention! Before washing the engine under cold water from a washing unit or a steam generator, cover the generator, fuse box, brake fluid reservoir with plastic bags.

Seat upholstery care and cleaning

Fabric cases

Clean the covers with a vacuum cleaner or a fairly stiff brush. If heavily soiled, they can be cleaned with foam.

Grease and oil stains can be removed with washing gasoline or stain remover.

At the same time, do not directly moisten the place of contamination with the stain remover, because in this case stains will necessarily appear on the fabric around the place that was wetted with the stain remover. Work the stain in a circle, moving from outside to inside. Other contaminants are usually removed with warm soapy water.

Leather cases

When exposed to strong sunlight and for long periods of parking, remove the covers so that they do not fade.

Use a lightly dampened knit or woolen cloth to clean the leather surfaces without soaking the leather or seams through. Finally, wipe damp skin with a dry, clean cloth.

Heavily soiled leather surfaces can be treated with mild detergent solutions without bleach (2 tablespoons per 1 liter of water). Carefully remove grease and oil stains with washing gasoline without wiping them.

Treat lacquered leather seats with a commercially available leather cleaner after cleaning. Such funds can be purchased at a specialized store or at an auto shop. Shake well before use and apply a thin layer with a soft cloth. After drying, wipe the surface with a clean soft cloth. Perform this treatment once every 6 months if the external influence is normal.

Painting

Work on editing the body and restoring the paintwork of a car requires great skills and knowledge both about the materials themselves, with which they will need to be worked or processed, and about their application. These skills are usually developed over many years. For this reason, this manual only deals with repairing minor damage to the paintwork.

When painting, use paint that is completely identical to that applied to the car body. Even the slightest deviations in color are striking. The corresponding paint color can be found in the paint number on the rating plate.

If, after painting the damaged areas, the original paintwork differs from the paint used during the restoration work, then the cause should be sought in the change in the shade of the original coating under the influence of time, solar ultraviolet radiation, sudden temperature changes and extreme weather conditions, as well as the influence of chemical emissions e.g. in industrial areas. In addition, surface damage, discoloration and fading of the paint result from the use of paint care products that do not meet the requirements of the vehicle manufacturer.

The paintwork of the body is two-layer. The first layer is applied with the main paint (primer), the second - colorless varnish. When varnishing, a transparent varnish is sprayed onto the base paint that has not yet dried. When carrying out subsequent varnishing work, there is a high risk that the newly painted areas will still be visible, because even the different viscosity of the repair and original varnish leads to a change in color. Restoration of damaged paintwork

To prevent the appearance of rust, it is recommended to regularly repair even minor damage to the paintwork. This will prevent the spread of rust.

If small scratches or damage to the paintwork from stone impacts do not reach «pure» metal, it is enough to cover them with varnish of the appropriate shade. For these needs, specialized stores offer small tubes of varnish along with a brush. In addition, a self-adhesive film coated with an appropriate varnish can be purchased for gluing places with barely visible damage.

Deeper scratches from stones, where rust has already appeared in the form of points, should be treated especially carefully. Use a knife or small screwdriver to remove the rust until «clean» metal. In this case, special care is required so that even microscopic traces of rust do not remain on the metal. There are so-called «erasers» rust remover, which is a small metal brush.

Treated scratches should be wiped dry and degreased. To do this, the scratch itself, as well as the adjacent surface, must be cleaned with a silicone remover.

Prime the scratch with a thin brush. Given that the primer is usually sold in aerosol cans, then apply it to the lid of the can and dip the brush.

After the primer dries with a brush, apply a layer of varnish from a tube. In such tubes with varnish, the brush is fixed on the lid. If the desired varnish is purchased in an aerosol package, then apply it to the lid of the spray can and use a regular paint brush. Apply only one thin coat of lacquer at a time. This will prevent the varnish from spreading. Let the paint dry well. Repeat these steps until the scratch is completely aligned with the surface of the body.

Body straightening

Small dents in the bodywork can be smoothed out with a straightening hammer and an appropriate anvil (heels). If the body is rusted in some places, then it is recommended, depending on the degree of rust damage, to replace the corresponding part or weld it.

Smooth out small dents on the body with a straightening hammer. On the opposite side of the dent, hold the heel of the anvil and use a hammer to gently hit the area to be flattened. It is not recommended to apply strong blows, because in such cases the metal is stretched and the dent cannot be straightened properly. Tapping with a hammer should go in the direction from the edge to the center of the dent.

Always check the straightened surface by touch, achieving the desired shape. Minor irregularities can later be leveled with putty.

Rust and remnants of the old paintwork after straightening must be carefully removed from the restored area. This is done with a grinder and coarse sandpaper (120). Cover or apply protective tape to nearby decorative trims or plastic parts to avoid damage if the grinder slips off.

Wash the vehicle before refinishing. Carry out restoration work at an air temperature above 12°C, but not in an open place under the bright sun or in windy weather.

Adjacent surfaces around the place where the repair will be carried out, paste over the protective film well so as not to damage their paintwork.

Remove any rust you can see with a wire brush, screwdriver, or 120 grit sandpaper.

Then sand the edges around the area to be treated with 320 grit sandpaper, capturing the undamaged paintwork by about 1-2 cm.

On galvanized body parts, remove, if possible, only the top layer of paint, leaving the primer and not sanding to «naked» zinc.

Wipe the repair area with a clean cloth soaked in nitro thinner and let it dry.

The primer as well as the base coat must be from the same manufacturer to avoid possible incompatibility emblems. Otherwise, the varnish may blister or peel off.

The primer from an aerosol can is applied to the prepared place from a distance of 25 cm in a very thin but dense layer. To avoid getting paint on nearby parts, they should be covered with newspapers or film.

After 10-15 minutes, you can apply a new layer of primer. If putty is to be applied over the primer to smooth out irregularities, then the primer must be allowed to dry well.

There are two types of putty: two-component and for finishing, ready to use. As for the two-component, a hardener is added to it before use. The resulting mixture quickly hardens, so it must be used quickly enough for its intended purpose. This putty is used to level relatively large body irregularities.

Finishing putty, ready for use, is a thick mass, which is convenient to level small irregularities. This putty can be applied in several layers. Both types of putty are sold in tubes and jars.

Finishing putty, ready to use, also available in aerosol packaging.

Attention! Despite the fact that the packaging indicates that the putty can be applied to «clean» metal, we recommend first treating the surface with a primer to protect against corrosion.

Apply a two-component putty to the leveled and prepared area. Let the putty dry. Before using the putty, read the instructions for its use.

After the putty has dried, smooth out the unevenness by hand or with a vibration sander and sanding paper, grit 180. Sanding can be done with the so-called wet sanding. To do this, the area to be sanded, as well as the corresponding sanding paper, should be well moistened with water from time to time.

When finished, wipe the area clean and dry.

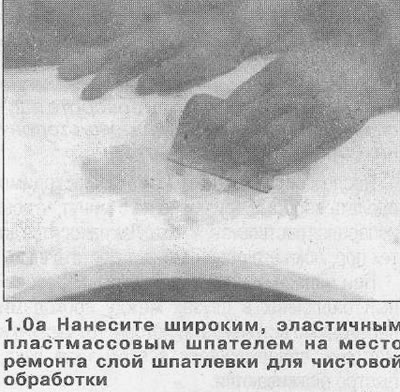

Use a wide, flexible plastic trowel to apply a layer of finishing putty to the repair area and let it dry for about two hours. When repairing convex or rounded areas, it is recommended to apply finishing putty from an aerosol can.

Depending on the thickness of the applied finishing layer of putty, it must be allowed to dry for 2-3 hours.

Sanding paper has different grain sizes. The smaller the number indicating its grit, the coarser the sandpaper. For sanding two-component putty, it is recommended to use sanding paper with a grit of 180-240.

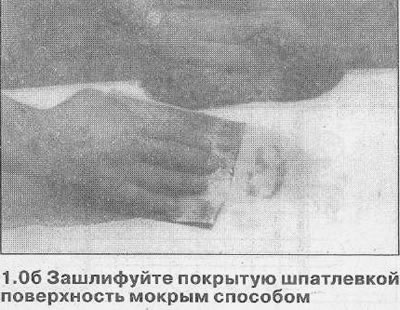

The finishing putty and the old paintwork are wet sanded with 360 grit sandpaper. For wet finishing, it is recommended to use 600 grit sandpaper.

Sand the putty-coated surface wet, regularly squeezing water from a sponge onto the area to be sanded and using 360 grit sanding paper.

Sanding paper with a grit of 600 is best suited for wet finishing. In this case, the sanding captures adjacent areas with an undamaged varnish coating, on which a new varnish will be applied. Sanding should only be carried out in the direction of travel of the vehicle. Scratches that appear on intact varnish will then be almost invisible.

Before applying the lacquer coating, the prepared surface itself, as well as areas adjacent to the damaged area no narrower than a palm, must be cleaned of grease and silicone residues. Silicone solvent is best suited for processing.

After grinding, carefully clean the repaired surface, and carefully and precisely cover the adjacent surfaces with newspapers or film. If varnishing is to be done on the fenders, also cover the tires and shock absorbers.

Cover the surfaces adjacent to the place of applying the varnish so as to ensure a smooth transition between the new and the old varnish coating. If there is a decorative trim or an edge of a body part nearby, then cover the whole place with a new varnish up to the trim.

As already mentioned, in order to avoid unnecessary problems when applying varnish, a varnish of the same company as the primer should be used.

Attention! It is recommended that before applying varnish to the repaired surface, practice on a suitable body part, for example, on an old wing.

The surface to be varnished must be dry and clean, free of dust. If possible, blow out the repair site with compressed air.

Moisten the floor on which the car is installed to prevent dust formation.

Wipe the repair site over the entire surface and with the grip of the undamaged lacquer coating with silicone solvent. The adhesive strength of the applied varnish is increased if the surface to be repaired is rubbed with a silicone-free polishing paste.

Shake the contents of the aerosol can for at least 3-5 minutes so that a homogeneous mass is formed and there are no varnish spots during application.

If varnish is to be applied «metallic», then after shaking the can, spray a little varnish on the cardboard. Particles «metallica», adhering to the inner surface of the atomizer will be removed.

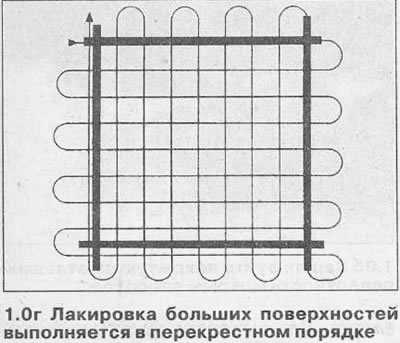

Lacquering of large surfaces, whether vertical or horizontal, is carried out in a cross pattern. Varnish spraying starts outside the surface to be coated and ends also outside the zone of the surface to be coated by turning the spray gun in the opposite direction.

For small surfaces, varnish in a spiral from outside to inside to avoid a large spray range.

Move the spray can at a constant speed, maintaining an equal distance from the surface to be treated. The optimal distance to the treated surface is approximately 25 cm.

The joint between the new and old lacquer is invisible if the lacquer is applied in at least four passes. At the same time, each new thin layer of varnish comes a little on the old varnish coating. This means that each new layer overlaps the previous one by 2-3 cm.

Attention! If the varnish is applied from a very close distance or if the can is moved too slowly, so-called sagging will form on the treated surface. This means that a large amount of varnish has got into some places and its spreading has occurred. The same sags are formed when the sprayer is turned in the opposite direction not over the protective coating.

After each application of the varnish, it is necessary to take a break for about 5 minutes so that the varnish thinner evaporates. The varnish is applied until its layer is sufficient.

When applying varnish «metallic» the aerosol can must be shaken between passes, because the metal particles contained in this type of varnish settle quickly.

Attention! Ensure that the color of the repaired surface is identical with the main paintwork during varnishing «metallic» very difficult. The so-called pigmentation (distribution of aluminum particles) it will be more uniform if, during the last pass, the varnish is sprayed from a distance of not 25 cm, but from about 30 cm. In this way, a certain uniformity of the color of the varnish coating is also achieved. With slow spraying of the paintwork, its color becomes more saturated and dark, and when the can is moved quickly, it becomes lighter.

Base coat of varnish «metallic» acquires its brilliance only after a layer of colorless varnish is applied to it. In this case, 3-4 thin layers of colorless varnish are also applied. At the same time, a break is made each time for a few minutes so that the previous layer dries.

Allow the base coat to dry for at least 30 minutes before applying the clear coat. A colorless varnish is applied to the base coat of the area to be repaired, overlapping with the previous paintwork. The width of this entry is approximately the width of the palm.

Before applying a clear coat, the protective cover on adjacent parts must be moved by approximately this distance.

Clean the sprayer of lacquer residue. Turn the can upside down and, pressing the sprayer, hold it in this position until the varnish is completely out.

Remove the protective cover from nearby parts after painting is complete. If the lacquer was sprayed only up to the edge of the protective cover, not with an approach to it, then the formation of a drip at the joint is not excluded.

Let the newly varnished surface dry. The drying process can be accelerated by a suitable heater or a powerful photo lamp.

Attention! Do not dry the varnish with a fan heater. The dust raised by the fan will settle on the still wet varnish.

After the paintwork has dried, but not earlier than after 48 hours, you can carefully remove the varnish that has settled on the surface of nearby parts. To do this, use a soft polishing agent or cotton swabs. Polishing should be done in the longitudinal direction.

Visitor comments