The coolant must provide a cooling and anti-corrosion effect all year round. Before the start of the winter season, you need to check the concentration of the coolant.

The expansion tank is a container for coolant. It accumulates liquid expanding when heated, and after cooling the engine, it flows back into the cooling circuit. As a result, the circuit constantly remains filled, and the cooling is full. Topping up the coolant is also carried out in the expansion tank.

The tank cap has a safety valve that provides a constant pressure in the cooling system of approximately 1.3 bar and a boiling point of the coolant of about 125°C. To prevent compression of the coolant hoses when the engine cools, the cover also has a low pressure valve that opens when the system pressure drops to about 0.10 bar and lets air into the cooling system.

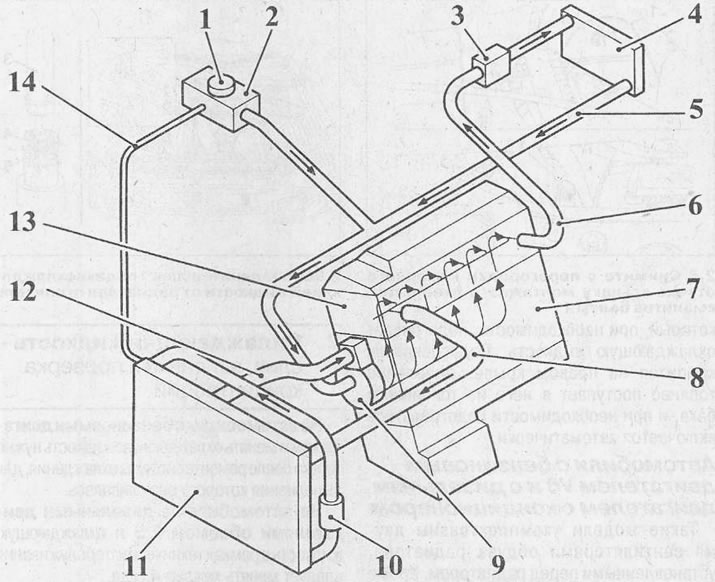

Coolant in the radiator flows from top to bottom (vertical flow radiator). In this case, the liquid is cooled by the oncoming air flow when the car is moving or by the air flow from the electric fan. The coolant is taken from the lower radiator reservoir by a water pump through the lower hose and fed into the cooling jacket of the head and cylinder block.

The design of the cylinder head is such that the cooling channels run close to the valve seats and form an intensive cooling zone. From here, the coolant enters the cylinder block, and from the block - to the thermostat and to the upper radiator reservoir, from where a new cooling cycle begins (see illustration 1.0).

1.0 Coolant circuit. Vehicles with a 2.5L diesel engine

1 - expansion tank cap

2 - expansion tank

3 - heater valve

4 - heater radiator

5 - return pipeline of the cooling liquid

6 - coolant supply pipeline

7 - cylinder block

8 - pipeline for returning coolant to the radiator

9 - water pump

10 - additional pump

11 - radiator

12 - pipeline for supplying coolant from the radiator to the cooling jacket

13 - cylinder head

14 - ventilation hose

When the coolant temperature is below 92°C (for 2.5 l diesel engines below 80°C) the thermostat remains closed. In this case, the coolant is supplied to the circuit through the bypass channel of the water pump, and is taken by the pump from the thermostat housing. This ensures that the engine warms up quickly and evenly. At a temperature of 92°C, the thermostat begins to open and at a temperature of about 107°C it opens completely.

An electric fan provides additional liquid cooling. As soon as the coolant temperature rises to 100°C, the thermal switch turns on the radiator fan. As soon as the coolant temperature falls below 95°C, the fan automatically turns off.

Vehicles with a 2.5L diesel engine

The fan is located on the pump shaft and is driven by a ribbed belt. There is a viscous coupling between the pump shaft and the fan (viscous coupling). As soon as the temperature of the air blowing on the radiator reaches approximately 82°C, the bimetallic plate of the viscous coupling turns on the fan. It starts to rotate at a high speed and works until the temperature of the air blowing the radiator drops to 60°C.

At this temperature, the viscous coupling disengages and the fan rotates at a slower speed. Due to the intermittent operation of the fan, the useful power of the engine is increased and fuel consumption is reduced.

Direct injection diesel vehicles

This type of engine has a low heat output due to its high efficiency. Therefore, it needs an additional heater, which, if necessary, heats the coolant. The heater is mounted on the right wing. Diesel fuel enters it from the fuel tank, and if necessary, the heater turns on automatically.

Vehicles with V6 petrol and diesel engines with air conditioning

Such models are equipped with two radiator fans installed in front of the radiator. In addition, there is an additional electrically driven water pump on the radiator for additional fluid cooling.

Attention! The radiator fan can automatically turn on and off repeatedly even when the engine is turned off and the ignition is on (Ignition key in position «II»). This occurs in particular in hot weather due to the accumulation of heat in the engine compartment. When working in the engine compartment with a warm engine, you must always keep in mind the possibility of sudden activation of the fan. Therefore, if possible, turn off the ignition beforehand.

Attention! When working on the cooling system, make sure that coolant does not get on the toothed belt. It can damage the belt material so much that it breaks after a while, causing serious engine damage.

Visitor comments