On vehicles with 2.5 liter diesel engines, the coolant must be changed every 4 years as part of maintenance.

If, as a result of the repair, a new cylinder head, its gasket, radiator, heater or engine was installed, then it is imperative to fill in new coolant. This is due to the fact that the anti-corrosion additives present in the liquid are deposited on new parts made from an alloy of light metals and form a protective film on them. In the old liquid, such particles are no longer enough.

Draining liquid

1. Unscrew the mounting bolts and remove, if any, the mudguard (protection) engine (see relevant chapter).

2. Unscrew and remove the cap from the filler neck of the expansion tank.'

Attention! When the engine is hot, it is recommended to put a thick layer of rags on the cover to protect yourself from burns from spilled hot liquid or steam. Slowly unscrew the cap and, depressurizing the system, remove it. The cover should be removed when the coolant temperature does not exceed 90°C!

3. Place a container under the radiator to collect the coolant.

4. Unscrew plug 1 from the drain hole on the radiator by hand and completely drain the liquid. The drain hole is located at the front left, above the front axle beam, when viewed in the direction of travel (see illustration).

5. Vehicles with a 2.5L diesel engine. Unscrew the plug from the drain hole on the cylinder block, under the exhaust manifold, if, for example, it needs to be repaired (see arrow in illustration). After draining, screw the plug back in place with a force of 40 Nm.

Refueling

Attention! From 9/2000 red or orange liquid is poured into the engine cooling system. The cooling system of cars produced before 8/2000 was filled with silicate coolant, which has a blue-green color. Only blue-green liquid should be poured into cars of this release. Under no circumstances should liquids of different colors be mixed, as this can lead to serious engine damage!

6. Screw in and tighten the drain plug on the radiator.

7. Fill the coolant into the expansion tank up to mark 1 «KALT» (cold engine).

Vehicles with V6 engine

8. Remove the mounting hole cover from the partition of the engine compartment by unscrewing the bolts 1 (see illustration).

9. Disconnect the hose 1 for supplying coolant from the branch pipe 3 of the heater radiator by pressing on the fixing leash 4 and pulling the retaining ring 5 in the direction of travel (see illustration). Return hose 2 does not need to be disconnected.

10. Fill the disconnected hose completely with coolant.

11. Connect a hose to a branch pipe and fix it with a lock ring.

12. Add, if necessary, coolant to the expansion tank, bringing its level to the mark «KALT».

13. Replace the mounting hole cover on the bulkhead of the engine compartment.

All engines

14. Screw on a jellied mouth of a broad tank a cover and tighten it against the stop.

15. Warm up the engine at 3000 rpm to open the thermostat. The lower radiator hose will then heat up.

Attention! When the engine warms up, air is removed from the cooling system automatically.

16. Check up tightness of system of cooling.

17. Stop the engine and let it cool down. Then check the coolant level again and top up if necessary. When the engine is warm, the coolant level should be slightly above the mark «KALT» on the expansion tank.

18. Reinstall, if equipped, the engine mudguard.

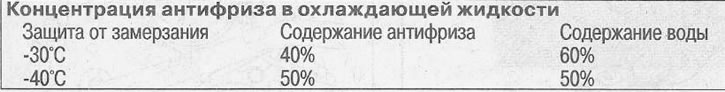

Concentration test

The cooling system is filled all year round with a mixture of water, antifreeze and anti-corrosion agent. This mixture protects against damage caused by freezing, corrosion, lime deposits and, in addition, increases the boiling point of the coolant. In the cooling circuit, when the liquid is heated, as a result of its expansion, excess pressure arises, which also contributes to an increase in the boiling point of the coolant. Due to the heating of the coolant and its expansion, pressure is formed in the cooling system, which also contributes to an increase in the boiling point of the coolant. The pressure in the system is regulated by a valve installed on the cap of the expansion tank. The valve opens at a pressure of approx. 1.3 bar. A high boiling point of the coolant is necessary for the perfect operation of the engine cooling system. Too low a boiling point of the fluid can lead to heat lock, which impedes the circulation of the coolant and impairs engine cooling. For this reason, the cooling system must always be filled with a mixture of cooling concentrate throughout the year.

The radiator and heater are made of aluminum, therefore, only liquid recommended by OPEL should be poured into the cooling system in order to prevent premature corrosion of these components.

Attention! There are two types of coolant used in OPEL.C9/2000 vehicles. red or orange liquid is poured into the engine cooling system. The cooling system of cars produced before 8/2000 was filled with silicate coolant, which has a blue-green color. Only blue-green liquid should be poured into cars of this release. Under no circumstances should liquids of different colors be mixed, as this can lead to serious engine damage! Mixing of coolant of the same color is allowed.

Visitor comments