Attention! Place the removed head on wooden blocks so as not to damage the nozzles, glow plugs and valves.

2. Disconnect from the cylinder head the exhaust manifold together with the turbocharger, the alternator mounting bracket, the bottom of the intake manifold and the engine lifting lugs.

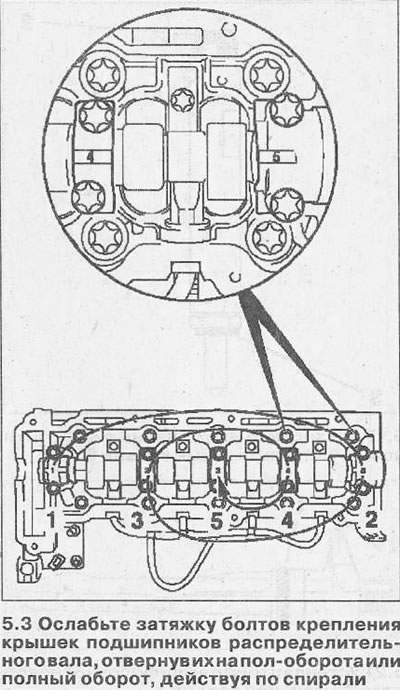

Attention! Mark all camshaft bearing caps before removing them so that they can be reinstalled in their original positions during reassembly.

3. Loosen the camshaft bearing cap bolts by backing out a half turn or a full turn in a spiral motion as shown in the illustration. After loosening the bolts of all covers, unscrew them and remove the camshaft (see illustration).

Attention! Place the removed nozzles, rocker arms and hydraulic tappets in the order of their dismantling so that they can be installed in their original places during assembly.

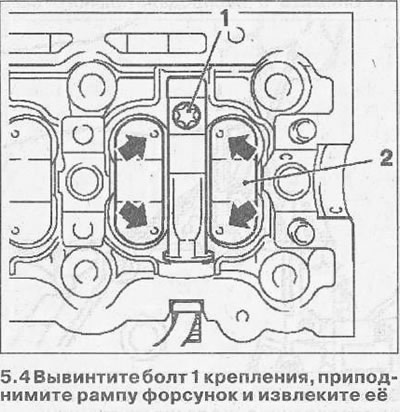

4. Unscrew the fastening bolt 1, lift the injector rail and remove it (see illustration).

5. Remove the rocker arms 2 of the valve drive, having previously marked their position (see illustration 5.4). Reference marks on the rocker arms in the form of arrows are located on the ends adjacent to the injector ramp.

6. Remove the o-rings from the fuel injectors.

7. Screw the KM-931 adapter onto the fuel injectors, install the KM-328-B puller on it, unscrew the fuel injectors and remove the heat-shielding gaskets.

8. Unscrew the glow plugs using the KM-980 key.

9. Designate valves and their seats.

10. Compress the valve springs using a puller 1 KM-348 and an adapter 2 KM-653-A, remove crackers, remove the plate and springs (see illustration).

11. Using a KM-840 puller, remove the oil seals and remove the support washers of the lower (outdoor) valve springs.

12. Clean all parts.

13. Inspect all parts and their surfaces for damage and wear.

14. Grease valves with engine oil and establish them in directing on a head of the block of cylinders, being guided by designations made before removal.

15. Install the support washers of the lower springs and oil seals 1 (see illustration).

16. Install the springs and their plates, compress the springs with the KM-348 puller and KM-653-A adapter and insert crackers.

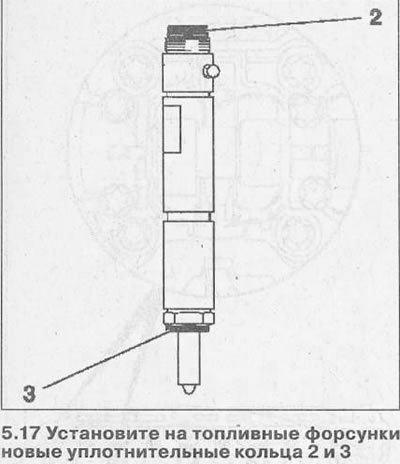

17. Install new O-rings 2 and 3 on the fuel injectors and apply white sealant to them (see illustration).

18. Install the fuel injectors on the cylinder head.

19. Screw in the glow plugs, tightening them to 10 Nm.

20. Grease hydraulic pushers with engine oil and establish them in on a head of the block of cylinders according to the designations made before removal.

21. Install a new sealing ring 1 on the injector rail and lubricate it with a thin layer of white sealant (see illustration).

22. Install the injector rail into the cylinder head, being careful not to damage the O-ring.

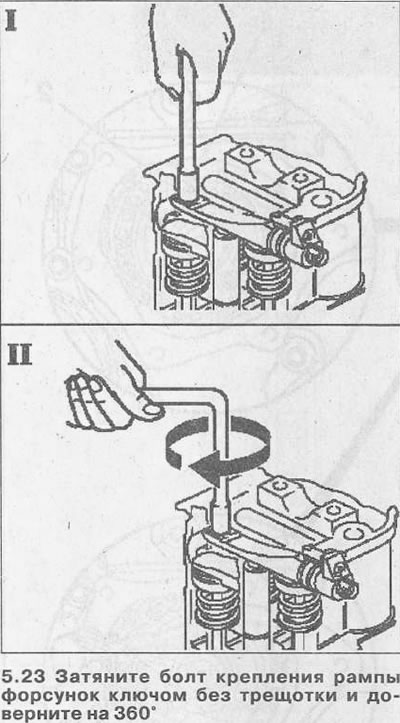

23. Fix the injector rail with a new bolt, tighten it with a wrench without a ratchet and tighten it 360° (see illustration).

Attention! Only this procedure of fixing the injector rail ensures the correct fit of the rail on the injectors.

24. Establish rocker arms of valves in a head of the block of cylinders, being guided by the designations made before removal.

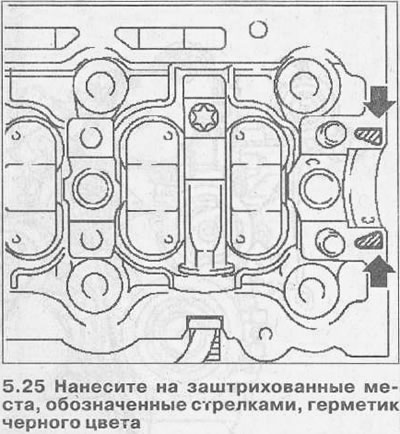

25. Apply black sealant to the shaded areas indicated by the arrows (see illustration).

26. Apply gray molybdenum grease to the mating surfaces of the rocker arms and camshaft and place the camshaft in the cylinder head.

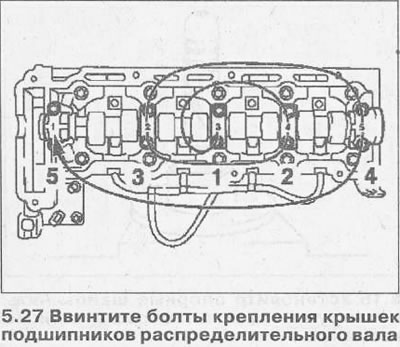

27. Establish covers of bearings of a camshaft, observing the designations made before removal, screw in bolts of their fastening and tighten bolts, acting on a spiral (see illustration). Pre-tighten all bolts a half turn or a full turn, and then, maintaining the specified order, tighten them with a force of 15 Nm.

28. Install the lower part of the intake manifold on the head of the block, replacing the old sealing gasket and fastening nuts with new ones. The tightening torque of the nuts is 22 Nm.

29. Connect the upper part of the intake manifold to the lower part of the intake manifold fixed to the cylinder head, replacing the gasket with a new one and tightening the mounting bolts with a force of 8 Nm.

30. Connect the exhaust manifold to the head, replacing the gasket and fastening nuts with new ones. The tightening torque of the nuts is 22 Nm.

31. Install the alternator mounting bracket, replacing its seal with a new one. The tightening torque of the bracket mounting bolts is 20 Nm.

32. Screw the eyelets to the head to lift the engine with a force of 20 Nm.

Visitor comments