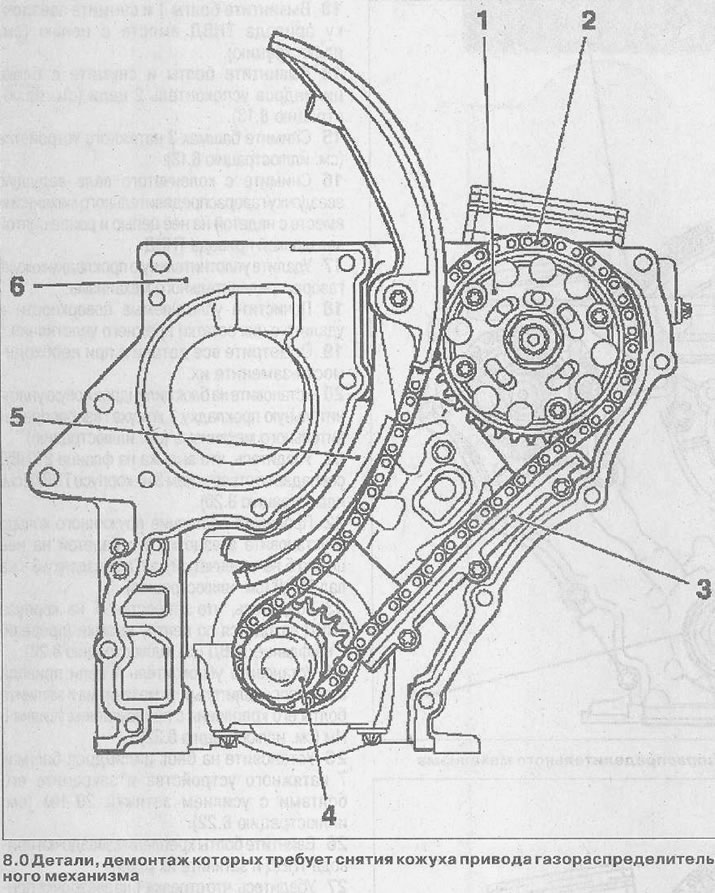

Attention! Dismantling the casing of the gas distribution mechanism is necessary when performing the following work:

- removal and installation of sprocket 1 of the injection pump drive,

- removal and installation of a chain 2 of a drive of the gas-distributing mechanism,

- removal and installation of damper 3 timing chains,

- removal and installation of the drive sprocket 4 of the gas distribution mechanism from the crankshaft,

- removal and installation of shoe 5 of the tensioner of the timing chain drive,

- removal and installation of casing 6 of the gas distribution mechanism drive,

- removal and installation of the oil pump (see illustration 8.0). The oil pump is not visible in the illustration.

Removing

1. Remove the engine (see relevant chapter).

2. Remove the oil pan (see relevant chapter).

3. Remove the cylinder head (see relevant chapter).

4. Disconnect wires from the generator.

5. Unscrew a bolt 1 fastenings of the generator and remove it (see illustration).

6. Remove the thrust pin 2 KM-929, with which the crankshaft was locked at TDC of the piston of cylinder No. 1 (see illustration).

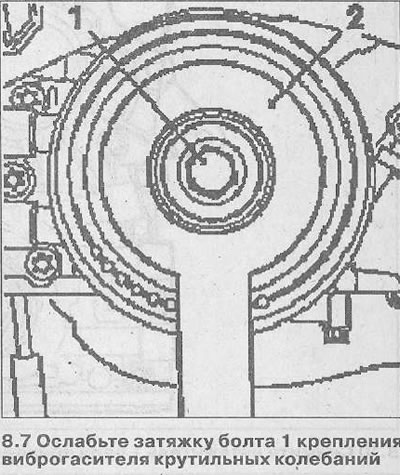

7. Loosen the bolt 1 fastening the vibration damper, holding the crankshaft from turning with tool 2 KM-977-2 (see illustration). The vibration damper bolt does not need to be fully unscrewed.

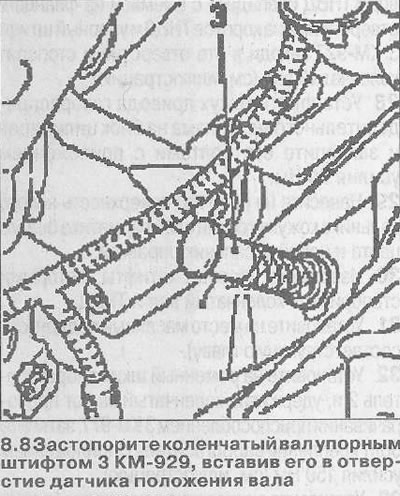

8. Lock the crankshaft with thrust pin 3 KM-929 by inserting it into the hole of the shaft position sensor (see illustration).

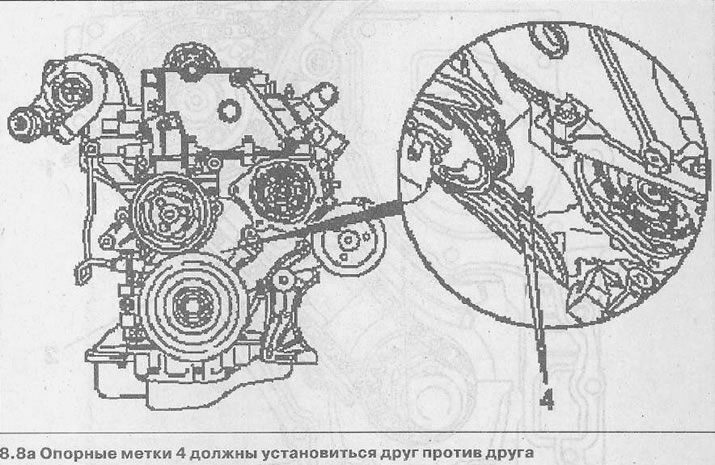

In this position of the crankshaft, reference marks 4 must be set opposite each other (see illustration 8.8a).

9. Remove the vibration damper from the accessory drive pulley.

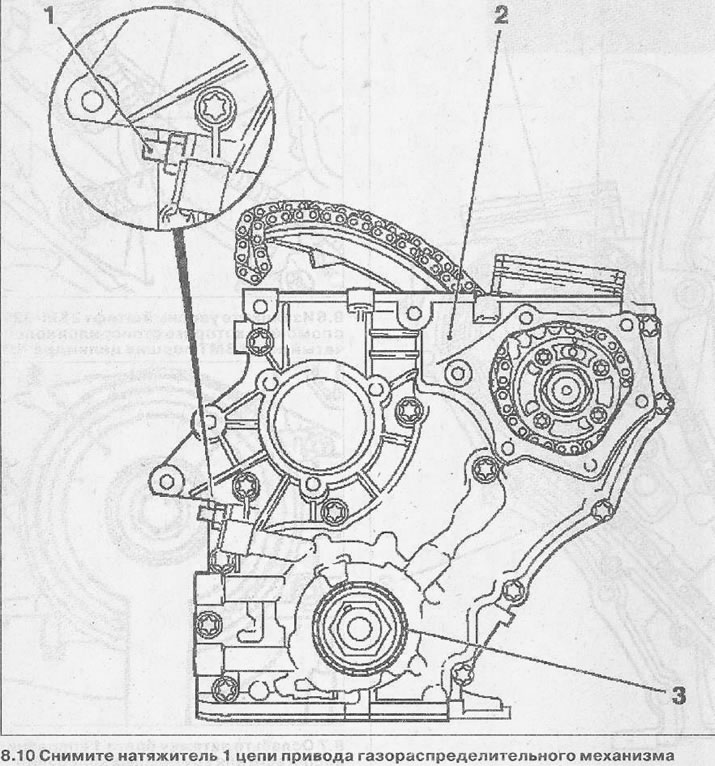

10. Remove tensioner 1 drive chain

11. Unscrew bolts of fastening of a casing 2 of a drive of the gas-distributing mechanism (see illustration 8.10).

Attention! Mark the mounting position of the bolts for their subsequent installation. The bolts are of different lengths.

12. Remove oil seal 3 from the casing of the timing gear drive and make sure that the sealing surfaces are not damaged (see illustration 8.10).

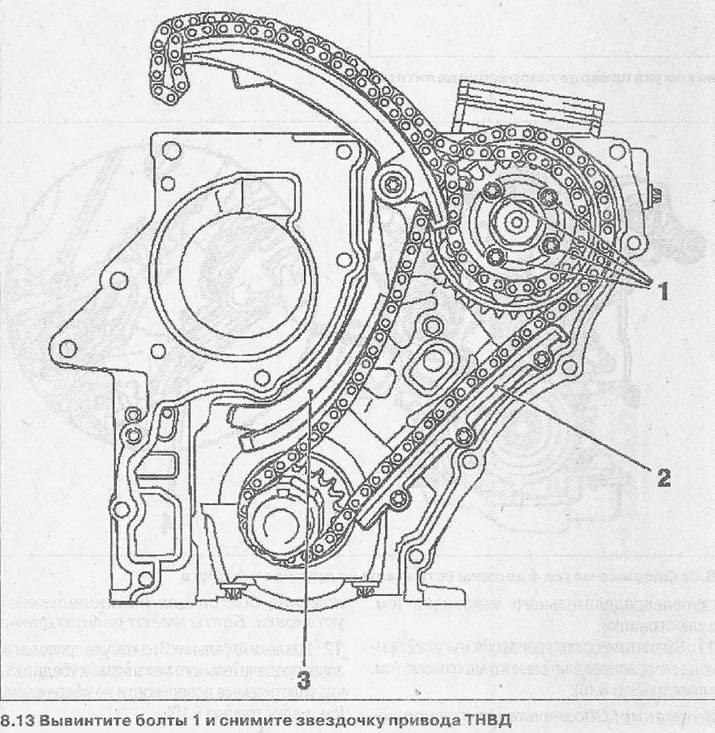

13. Unscrew the bolts 1 and remove the injection pump drive sprocket together with the chain (see illustration).

14. Unscrew the bolts and remove the damper 2 chains from the cylinder block (see illustration 8.13).

15. Remove shoe 3 tensioner (see illustration 8.13).

16. Remove the drive sprocket of the gas distribution mechanism from the crankshaft together with the chain put on it and the previously removed injection pump drive sprocket.

17. Remove the sealing gasket of the casing of the gas distribution mechanism.

18. Clean the sealing surfaces and remove the remnants of the old seal from them.

19. Inspect all parts and replace if necessary.

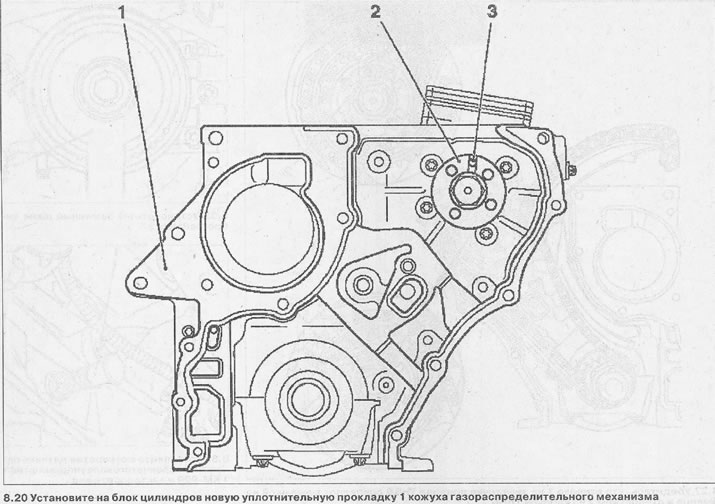

20. Install a new sealing gasket 1 of the timing cover on the cylinder block (see illustration).

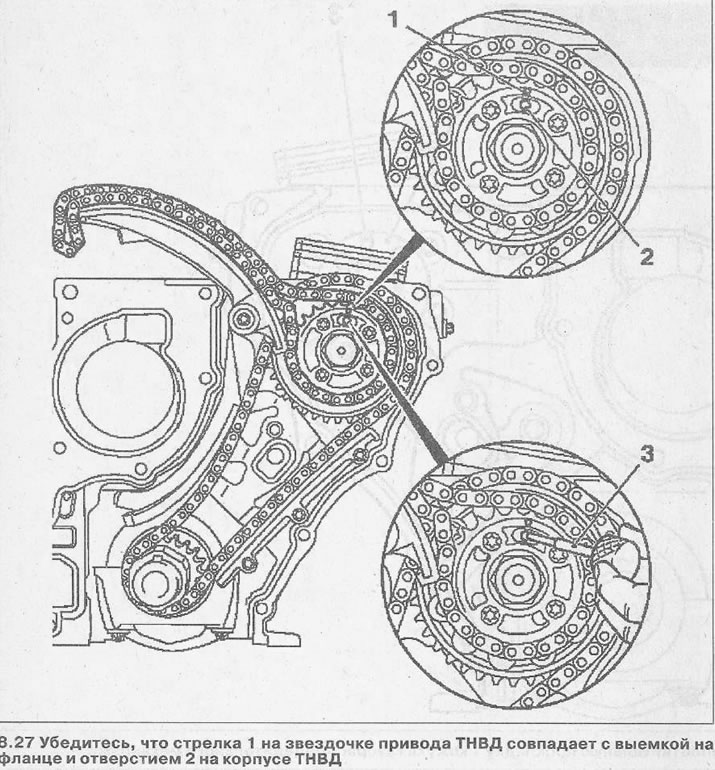

21. Make sure that the notch on the flange 2 of the injection pump matches the hole 3 on the injection pump housing (see illustration 8.20).

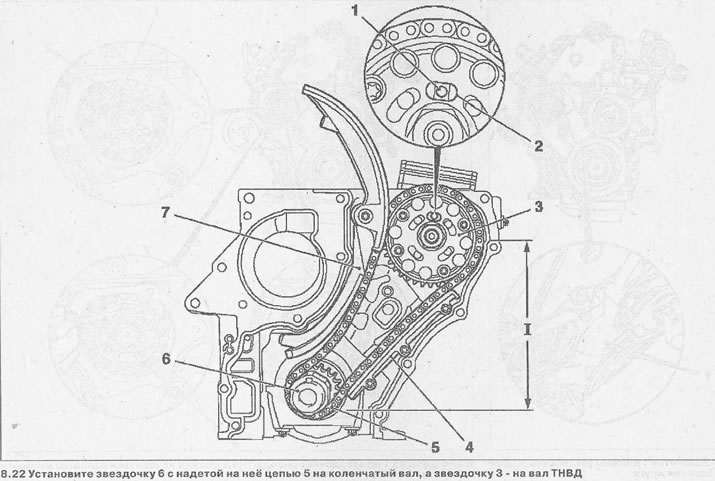

22. Check the condition of the spring ring and install the sprocket 6 with the chain 5 put on it on the crankshaft, and the sprocket 3 on the injection pump shaft (see illustration).

23. Make sure that hole 1 on the injection pump housing is in the center of the recess (slots) 2 on the injection pump flange (see illustration 8.22).

24. Install the damper 4 of the timing chain and tighten the bolts of its fastening with a force of 8 Nm (see illustration 8.22).

25. Install the shoe 7 of the tensioner on the cylinder block and fix it with bolts with a tightening torque of 20 Nm (see illustration 8.22).

26. Screw in the bolts for fastening the injection pump drive sprocket and tighten them by hand.

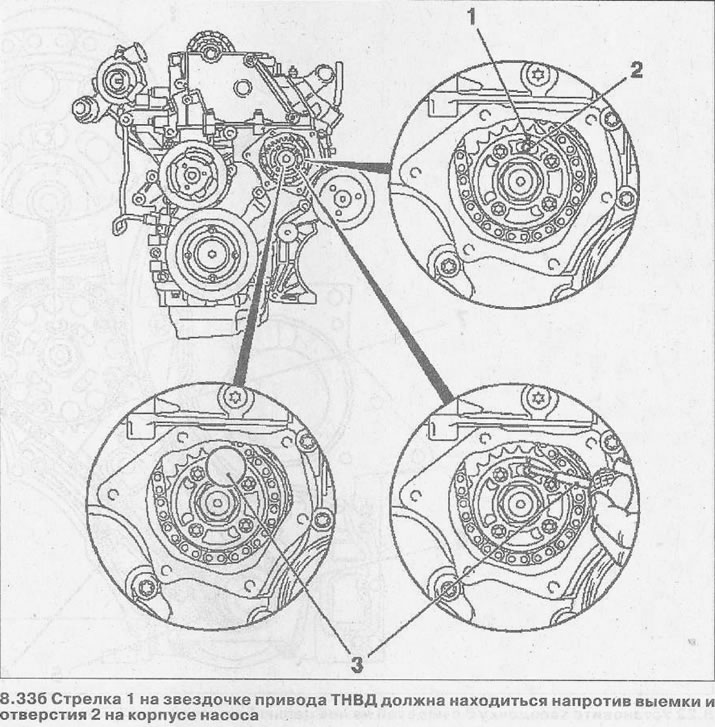

27. Make sure that arrow 1 on the injection pump drive sprocket coincides with the notch on the flange and hole 2 on the injection pump housing and stop pin 3 KM-927 enter this hole and lock the crankshaft (see illustration).

28. Install the timing cover on the cylinder block and bolt it with a force of 20 Nm.

29. Apply a thin layer of white sealant to the working surface of the new casing gland and stuff the gland with a mandrel.

30. Remove the thrust pins that locked the crankshaft and injection pump.

31. Reinstall the oil pan (see relevant chapter).

32. Install vibration damper 2 on the belt pulley and, holding the crankshaft from turning with tool 3 Km-977, tighten the vibration damper fastening bolt with a force of 150 Nm (see illustration).

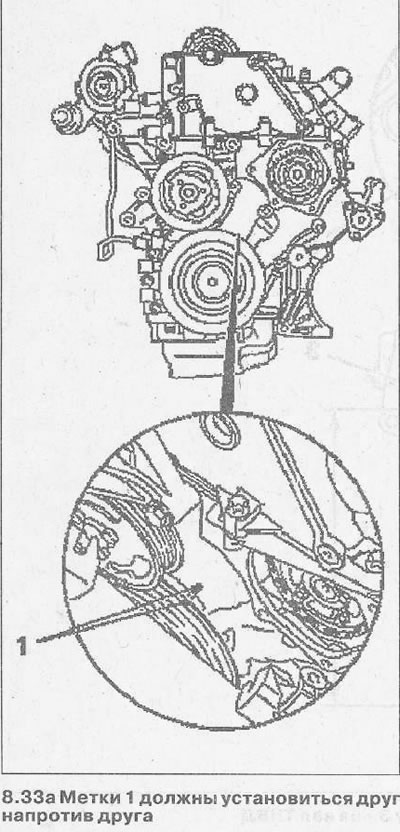

33. Install thrust pin 1 KM-929 into the crankshaft position sensor hole and lock the shaft (see illustration). In this position of the crankshaft, the alignment marks 1 should be set opposite each other, and the arrow 1 on the injection pump drive sprocket should be opposite the recess and hole 2 on the pump housing (see illustrations 8.33a 8.33b).

34. Lock the injection pump by inserting a thrust pin 3 KM-927 into hole 2 (see illustration 8.336).

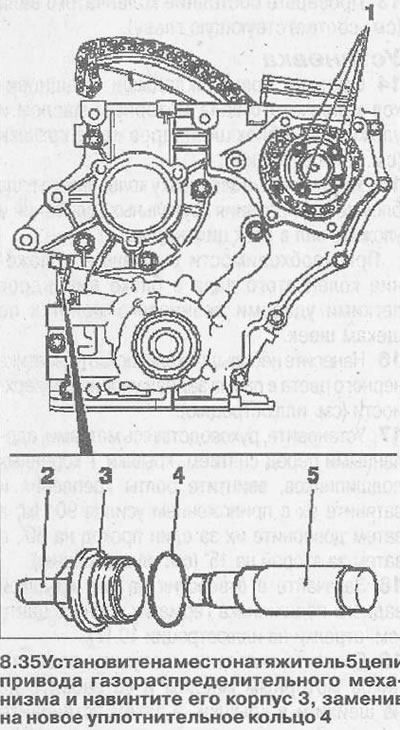

35. Reinstall the tensioner 5 of the timing chain and screw on its housing 3, replacing it with a new sealing ring 4 (see illustration).

Subsequent installation of dismantled parts is carried out in the reverse order of removal.

Visitor comments