Removing

1. Disconnect the wire terminal «masses» (-) from the negative pole of the battery.

2. Remove the windshield wiper motor (see relevant chapter).

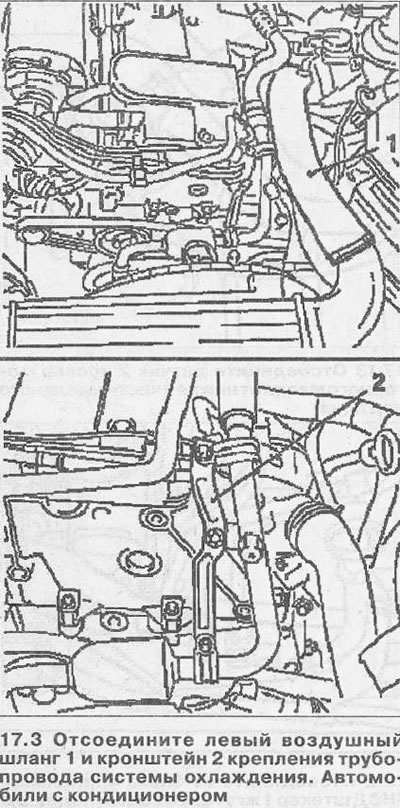

3. Cars with air conditioning. Disconnect the left air hose 1 and bracket 2 for fastening the cooling system pipeline and set them aside from the place of work (see illustration).

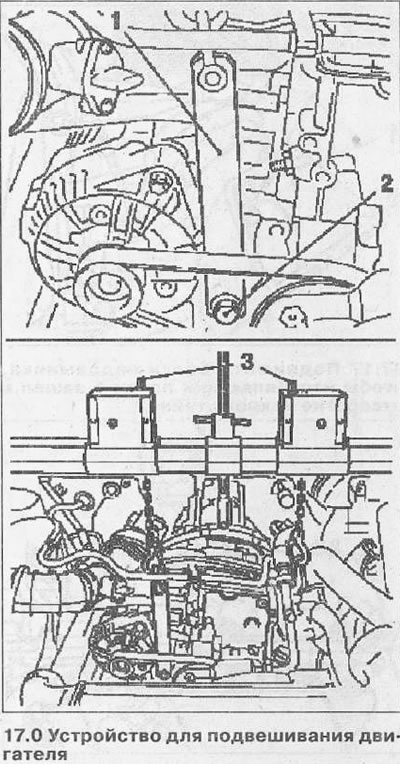

Attention! Diesel engines of 2.0 and 2.2 liters have a so-called double crankcase. To remove the bottom of the crankcase (oil pan) the engine must be supported from below and lifted. To do this, use a special device MKM-883 and a beam for hanging the engine (see illustration 17.0).

4. Attach a lifting device to the engine.

5. Remove the engine mudguard, unscrew the drain plug and drain the engine oil into a suitable container.

6. Screw the plug into the drain hole and tighten it with 10 Nm.

7. Unscrew bolts of fastening of forward support of the engine on a crossbeam.

8. Disconnect the steering arm using tool 3 KM-236-B (see illustration).

9. Install a garage jack under the subframe beam and raise it (see illustration).

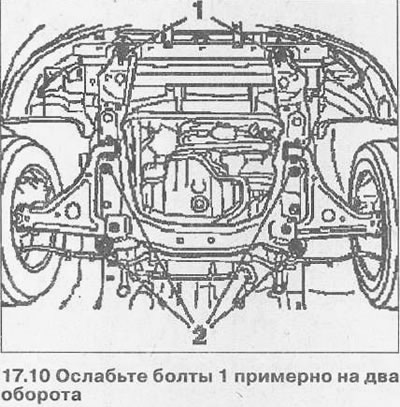

10. Loosen bolts 1 by about two turns, and unscrew bolts 2 (see illustration).

11. Carefully lower the subframe beam about 10 cm.

12. Unscrew the bolts securing the lower part 1 of the oil pan and carefully lower it by about 15 cm (see illustration).

Attention! Take some care not to damage the wires of the engine oil level sensor.

13. Disconnect the 2nd engine oil level sensor from the bottom of the oil pan (see illustration).

Installation

14. Clean the sealing surfaces and remove any remaining seal from them.

15. Reinstall the bottom of the oil pan along with a new seal and engine oil level sensor. The tightening torque of the sensor bolts is 8 Nm.

16. Fasten the lower part of the pallet to the upper one with a tightening torque of the fastening bolts of 8 Nm.

17. Raise the subframe beam so that the guide pin 1 goes into the hole on the bracket (see illustration).

18. Attach the subframe to the installation site and attach the engine mounts to it (see relevant chapter). The tightening torque for the support bolts is 55 Nm.

Further installation is carried out in the reverse order of removal.

19. Fill in engine oil, start the engine and check the tightness of the oil pan. Add oil if necessary.

Visitor comments