2. Gently spread the rings and remove them from the piston head (see illustration). Use two or three old feeler gauges to keep the rings from slipping into the already empty grooves. Be careful not to scratch the piston with the ends of the rings. Please note that the third (oil scraper) The ring consists of a spacer and two parts. Keep ring sets with the piston.

3. Clean off the main deposits from the piston head. Then clean it with a wire brush or fine sandpaper. The piston identification marks should now be visible.

4. Remove carbon deposits from the piston ring grooves using a piece of the old ring (break the ring in half, being careful not to cut your fingers). Be careful not to remove metal along with soot and do not scratch the walls of the grooves.

5. After removing carbon deposits, clean the piston/connecting rod assembly with kerosene or a suitable solvent and dry it thoroughly. Make sure the oil return holes in the annular grooves are not clogged.

6. If the pistons and cylinder walls are not damaged or worn and if the cylinder block does not need regrinding (see chapter 11), check the pistons as follows.

7. Carefully inspect each piston for cracks in the skirt, around the piston pin holes, and between the ring grooves.

8. Inspect the piston skirt for damage and the piston head for holes and burnt edges. If the skirt is scratched or nicked, or there are pits or burn marks on the piston crown, the engine may have overheated and/or misfired (incorrectly adjusted fuel mixture ratio or injection/ignition timing). Carefully check the cooling and lubrication systems. Burnt areas on the sides of the pistons indicate that a gas breakthrough has occurred. If any of the above damage is found, identify the causes and eliminate them, otherwise the damage will occur again. The cause may be an intake air leak, improper fuel/air mixture adjustment, incorrect ignition timing, or a defective injector.

9. Piston corrosion indicates that coolant has leaked into the combustion chamber and/or crankcase. Find the cause of the leak and fix it.

10. Measure the piston diameter perpendicular to the axis of the piston pin; compare results with specifications at the beginning of this Section. Please note that there are different size groups of nominal diameter pistons subject to manufacturing tolerances; the size group marking is imprinted on the piston head.

11. To determine the clearance between the piston and the cylinder wall, measure the bore diameter of the cylinder (see chapter 11) and piston skirt diameter (the difference between the measurements obtained will be the gap), or insert the piston into its corresponding cylinder bore, then determine the clearance by inserting a feeler gauge between the piston and the cylinder wall. The probe must be installed between the piston and the walls of the channel on one of the thrust surfaces at the base of the cylinder. If the clearance is too large, a new piston will be required. If the piston is stuck at the bottom of the cylinder and released at the top, the cylinder is tapered. If the feeler gauge sticks in some places as it moves around the perimeter of the piston in the cylinder bore, the cylinder is oval.

12. Repeat this procedure for the remaining pistons and cylinders. Worn pistons must be replaced.

13. Carefully inspect each connecting rod for damage: cracks around the bearing of the lower and upper heads. Check that the connecting rod is not bent or distorted. The connecting rod assemblies can only be checked in detail by an Opel dealer or an engine rebuilder.

14. On 2.0 and 2.5 liter engines, the piston pins are pressed into the bushing of the upper head of the connecting rod. Therefore, replacement of the piston and/or connecting rod should be done by an Opel dealer or engine rebuilder who has the necessary tools to remove and install the piston pins. If new pistons need to be installed, make sure they are the correct size group for each cylinder (see chapter 12).

Attention! Piston/connecting rod assemblies must not be separated. If any component requires replacement, the complete assembly must be replaced. Do not install a new piston on an old connecting rod or vice versa.

15. On 3.0L engines, floating piston pins secured with two circlips. On these engines, the pistons can be separated from the connecting rods as follows.

16. Using a small flathead screwdriver, remove the circlips and push out the piston pin. Mark the piston and connecting rod to ensure correct assembly. Discard retaining rings, use new ones when reassembling.

17. Inspect the piston pin and connecting rod bushing for damage and signs of wear. If worn, the pin and connecting rod must be replaced.

18. The connecting rods themselves should not need to be replaced unless the engine is jammed or otherwise mechanically damaged. Visually inspect the connecting rods, and if they appear to be bent, have an engine overhaul specialist for a detailed check.

19. Inspect all components, purchase new parts. New pistons will be fitted with pins and circlips. Retaining rings can also be purchased separately.

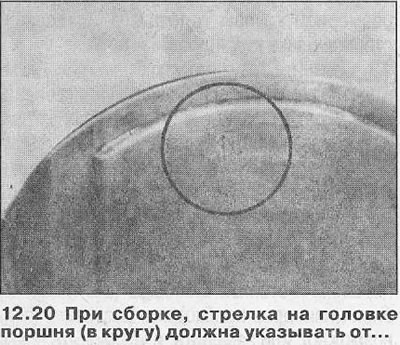

20. Assemble the piston and connecting rod so that the arrow on the piston head points away from the mark that is cast on one side of the lower connecting rod head (see illustrations).

21. Apply a small amount of clean engine oil to the piston pin. Insert it through the top end of the connecting rod into the piston. Then secure the pin with two new circlips, correctly positioning them in the grooves.

Visitor comments